Introduction to PCB Grounding

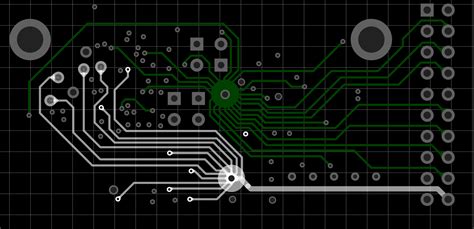

Printed Circuit Board (PCB) grounding is a crucial aspect of electronic design that ensures the proper functioning, reliability, and safety of electronic devices. Grounding techniques are employed to provide a low-impedance path for unwanted signals, minimize electromagnetic interference (EMI), and protect sensitive components from electrical noise and transients. In this comprehensive article, we will delve into the various PCB grounding techniques, their importance, and best practices for achieving optimal grounding in PCB designs.

The Importance of Proper PCB Grounding

Proper PCB grounding is essential for several reasons:

-

Signal Integrity: Effective grounding helps maintain signal integrity by providing a stable reference point for signals and reducing the impact of electrical noise and interference.

-

EMI Reduction: Grounding techniques help minimize electromagnetic interference (EMI) by providing a low-impedance path for high-frequency noise to be shunted away from sensitive components.

-

Safety: Proper grounding ensures the safety of users and equipment by providing a path for fault currents to be safely diverted to ground, preventing electric shock hazards.

-

Reliability: Well-designed grounding improves the overall reliability of electronic devices by minimizing the risk of component damage due to electrical transients and overvoltage conditions.

Types of PCB Grounding Techniques

There are several PCB grounding techniques commonly used in electronic design, each with its own advantages and considerations. Let’s explore some of the most prevalent techniques:

1. Single-Point Grounding

Single-point grounding, also known as star grounding, is a technique where all ground connections are made to a single point on the PCB. This central grounding point serves as a common reference for all ground connections, minimizing ground loops and reducing the impact of ground noise.

Advantages of single-point grounding:

– Simplifies the grounding scheme

– Minimizes ground loops

– Reduces ground noise and interference

Considerations for single-point grounding:

– May not be suitable for large or complex PCBs

– Requires careful placement of the central grounding point

– May introduce ground impedance issues at high frequencies

2. Multi-Point Grounding

Multi-point grounding involves connecting ground points at multiple locations on the PCB, typically using a ground plane or a grid of ground traces. This technique provides a low-impedance path for ground currents and helps distribute the ground potential evenly across the board.

Advantages of multi-point grounding:

– Provides a low-impedance ground path

– Distributes ground potential evenly

– Suitable for larger and more complex PCBs

Considerations for multi-point grounding:

– Requires careful design to avoid ground loops

– May introduce ground noise if not properly implemented

– Requires sufficient ground plane or trace coverage

3. Hybrid Grounding

Hybrid grounding combines elements of both single-point and multi-point grounding techniques. It involves using a single-point ground for sensitive analog circuits and a multi-point ground for digital circuits. This approach helps isolate sensitive analog signals from digital noise while still providing a low-impedance ground path for digital circuits.

Advantages of hybrid grounding:

– Isolates sensitive analog circuits from digital noise

– Combines benefits of single-point and multi-point grounding

– Suitable for mixed-signal PCBs

Considerations for hybrid grounding:

– Requires careful segregation of analog and digital grounds

– May introduce complexity in PCB layout and routing

– Requires appropriate ground plane or trace coverage for each section

4. Isolated Grounding

Isolated grounding involves separating the ground of a specific section or component from the main ground of the PCB. This technique is commonly used for sensitive analog circuits, high-power devices, or sections that require galvanic isolation for safety or noise reduction purposes.

Advantages of isolated grounding:

– Provides galvanic isolation for sensitive or high-power sections

– Reduces noise coupling between different sections of the PCB

– Enhances safety by preventing ground loops and fault currents

Considerations for isolated grounding:

– Requires careful design and implementation

– May introduce additional complexity in PCB layout and manufacturing

– Requires appropriate isolation techniques, such as optocouplers or transformers

Best Practices for PCB Grounding

To achieve optimal grounding in PCB designs, consider the following best practices:

-

Use a Solid Ground Plane: Incorporate a solid ground plane on one or more layers of the PCB to provide a low-impedance path for ground currents and minimize ground noise.

-

Minimize Ground Loops: Avoid creating ground loops by ensuring that ground connections follow a single path and do not form closed loops.

-

Separate Analog and Digital Grounds: Keep analog and digital grounds separate to prevent digital noise from interfering with sensitive analog signals. Use a hybrid grounding approach when necessary.

-

Provide Adequate Ground Connections: Ensure that all components have a proper ground connection to the ground plane or ground traces. Use sufficient via holes to connect ground planes on different layers.

-

Use Ground Pours: Utilize ground pours, also known as Copper fills, to provide additional grounding coverage and reduce ground impedance.

-

Consider High-Frequency Effects: At high frequencies, ground impedance becomes significant. Use techniques such as ground stitching, via fencing, or segmented ground planes to minimize high-frequency effects.

-

Employ Shielding Techniques: Use shielding techniques, such as grounded metal enclosures or shielded cables, to reduce EMI and protect sensitive circuits from external interference.

-

Follow Industry Standards: Adhere to industry standards and guidelines, such as IPC Standards, for PCB design and grounding practices to ensure consistency and reliability.

PCB Grounding Techniques for Specific Applications

Different applications may require specific grounding techniques to address unique challenges and requirements. Let’s explore a few common scenarios:

1. High-Speed Digital Circuits

High-speed digital circuits, such as those found in high-frequency processors or communication systems, require careful grounding to minimize signal integrity issues and EMI.

| Technique | Description |

|---|---|

| Ground Plane Partitioning | Divide the ground plane into separate regions for different circuit blocks to minimize noise coupling. |

| Via Stitching | Place ground vias closely spaced along critical signal paths to provide a low-impedance ground return path. |

| Differential Signaling | Use differential signaling techniques to reduce the impact of ground noise and improve signal integrity. |

2. Analog and Mixed-Signal Circuits

Analog and mixed-signal circuits, such as audio systems or data acquisition devices, require special attention to grounding to maintain signal fidelity and reduce noise.

| Technique | Description |

|---|---|

| Star Grounding | Use a single-point ground for sensitive analog circuits to minimize ground loops and noise coupling. |

| Ground Plane Splitting | Split the ground plane into separate analog and digital regions to isolate sensitive analog signals from digital noise. |

| Grounded Guard Rings | Surround sensitive analog components with grounded guard rings to provide shielding and reduce coupling from nearby noise sources. |

3. Power Electronics

Power electronic circuits, such as switching power supplies or motor drives, require robust grounding techniques to handle high currents and minimize EMI.

| Technique | Description |

|---|---|

| Power Ground Plane | Dedicate a separate ground plane for power circuitry to handle high currents and minimize voltage drops. |

| Ground Plane Cutouts | Use ground plane cutouts around high-current paths to minimize ground noise and improve current flow. |

| Shielding and Filtering | Employ shielding techniques and filtering components to reduce EMI and protect sensitive circuits from power supply noise. |

Frequently Asked Questions (FAQ)

- What is the difference between single-point and multi-point grounding?

-

Single-point grounding connects all ground points to a single central location, while multi-point grounding connects ground points at multiple locations on the PCB using a ground plane or grid.

-

How does proper grounding help reduce EMI in PCBs?

-

Proper grounding provides a low-impedance path for high-frequency noise to be shunted away from sensitive components, minimizing the impact of EMI on the system.

-

What is the purpose of a ground plane in PCB design?

-

A ground plane provides a low-impedance path for ground currents, distributes the ground potential evenly across the board, and helps minimize ground noise and interference.

-

How can I isolate sensitive analog circuits from digital noise?

-

Use techniques such as hybrid grounding, where analog and digital grounds are separated, and employ isolated grounding for sensitive analog sections to prevent noise coupling from digital circuits.

-

What are some best practices for PCB grounding in high-speed digital circuits?

- Use ground plane partitioning, via stitching, and differential signaling techniques to minimize signal integrity issues and EMI in high-speed digital circuits.

Conclusion

PCB grounding is a critical aspect of electronic design that directly impacts the performance, reliability, and safety of electronic devices. By understanding the various grounding techniques, such as single-point, multi-point, hybrid, and isolated grounding, designers can make informed decisions based on the specific requirements of their PCB projects.

Adhering to best practices, such as using solid ground planes, minimizing ground loops, separating analog and digital grounds, and employing appropriate shielding techniques, can significantly enhance the grounding effectiveness and overall system performance.

When designing PCBs for specific applications, such as high-speed digital circuits, analog and mixed-signal circuits, or power electronics, it is crucial to consider the unique grounding challenges and adopt techniques tailored to those scenarios.

By implementing proper PCB grounding techniques and following industry standards and guidelines, designers can ensure the optimal functioning, reliability, and safety of their electronic devices while minimizing the impact of electrical noise, interference, and EMI.

No responses yet