Introduction to PCB materials

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a platform for electronic components to be mounted and interconnected, enabling the creation of complex circuits that power our devices. The choice of materials used in PCB Fabrication plays a crucial role in determining the performance, reliability, and longevity of the final product. In this article, we will explore the various materials used in PCB manufacturing, their properties, and their applications.

Types of PCB Materials

1. FR-4

FR-4 (Flame Retardant 4) is the most commonly used material for PCB substrates. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin binder. FR-4 offers excellent mechanical strength, good insulation properties, and reasonable thermal stability. It is suitable for a wide range of applications, from consumer electronics to industrial equipment.

Properties of FR-4

| Property | Value |

|---|---|

| Dielectric Constant | 4.5 at 1 MHz |

| Dissipation Factor | 0.02 at 1 MHz |

| Thermal Conductivity | 0.3 W/mK |

| Thermal Expansion Coefficient | 14-16 ppm/°C |

| Flammability Rating | UL 94 V-0 |

2. High Tg FR-4

High Tg (Glass Transition Temperature) FR-4 is an enhanced version of standard FR-4. It features a higher glass transition temperature, typically around 170°C, compared to 130°C for standard FR-4. This improvement allows High Tg FR-4 to maintain its mechanical and electrical properties at higher temperatures, making it suitable for applications that require higher thermal stability, such as automotive and aerospace electronics.

3. Polyimide

Polyimide is a high-performance polymer material known for its excellent thermal stability, chemical resistance, and mechanical strength. It is often used in applications that require operation at high temperatures or exposure to harsh environments. Polyimide PCBs are commonly found in aerospace, military, and industrial applications.

Properties of Polyimide

| Property | Value |

|---|---|

| Dielectric Constant | 3.5 at 1 MHz |

| Dissipation Factor | 0.002 at 1 MHz |

| Thermal Conductivity | 0.2 W/mK |

| Thermal Expansion Coefficient | 12-14 ppm/°C |

| Continuous Operating Temperature | -269°C to 400°C |

4. Rogers Materials

Rogers Corporation offers a range of high-performance PCB materials designed for demanding applications. These materials are known for their excellent electrical properties, low dielectric loss, and controlled dielectric constants. Some popular Rogers materials include:

- RO4003C: A hydrocarbon ceramic laminate with low dielectric loss and stable dielectric constant. It is suitable for high-frequency applications, such as wireless communication and radar systems.

- RT/duroid 5870: A PTFE (polytetrafluoroethylene) composite material with low dielectric constant and low loss tangent. It is ideal for microwave and millimeter-wave applications.

- RO3000 series: A ceramic-filled PTFE material with low dielectric loss and stable dielectric constant. It is commonly used in high-frequency and high-speed digital applications.

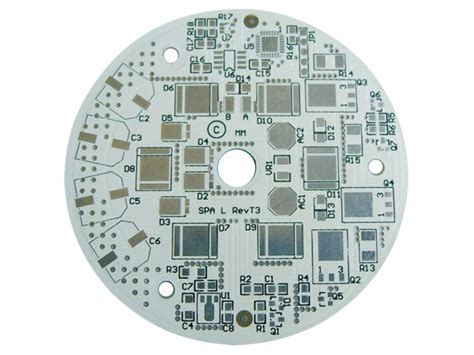

5. Aluminum PCBs

Aluminum PCBs consist of an aluminum substrate with a dielectric layer and copper traces on top. The aluminum substrate provides excellent thermal conductivity, allowing for efficient heat dissipation. Aluminum PCBs are often used in high-power applications, such as LED lighting and power electronics, where thermal management is critical.

6. Flexible PCBs

Flexible PCBs are made using flexible substrate materials, such as polyimide or polyester. They can bend and flex without damaging the circuits, making them suitable for applications that require conformity to irregular shapes or where space is limited. Flexible PCBs are commonly found in wearable devices, medical equipment, and automotive electronics.

PCB Material Selection Considerations

When selecting PCB materials, several factors should be considered to ensure optimal performance and reliability:

-

Electrical Properties: The dielectric constant, dissipation factor, and insulation resistance of the material should be suitable for the intended application. High-frequency and high-speed applications require materials with low dielectric loss and stable dielectric constants.

-

Thermal Properties: The thermal conductivity and thermal expansion coefficient of the material should be considered, especially for applications that generate significant heat or operate in varying temperature environments. Proper thermal management helps prevent component failure and ensures long-term reliability.

-

Mechanical Properties: The mechanical strength, flexibility, and dimensional stability of the material should be evaluated based on the application requirements. Some applications may require high mechanical strength, while others may need flexibility for conformity to specific shapes.

-

Environmental Factors: The material’s resistance to moisture, chemicals, and other environmental factors should be considered. Applications exposed to harsh environments may require materials with high chemical resistance and low moisture absorption.

-

Cost: The cost of the PCB material should be balanced against the performance requirements. Higher-performance materials tend to be more expensive, so it is essential to select a material that meets the necessary specifications while staying within budget constraints.

PCB Material Comparison

| Material | Dielectric Constant | Dissipation Factor | Thermal Conductivity (W/mK) | Thermal Expansion Coefficient (ppm/°C) |

|---|---|---|---|---|

| FR-4 | 4.5 at 1 MHz | 0.02 at 1 MHz | 0.3 | 14-16 |

| High Tg FR-4 | 4.5 at 1 MHz | 0.02 at 1 MHz | 0.3 | 14-16 |

| Polyimide | 3.5 at 1 MHz | 0.002 at 1 MHz | 0.2 | 12-14 |

| Rogers RO4003C | 3.38 at 10 GHz | 0.0027 at 10 GHz | 0.71 | 11 |

| Rogers RT/duroid 5870 | 2.33 at 10 GHz | 0.0012 at 10 GHz | 0.22 | 24 |

| Aluminum PCB | – | – | 150-200 | 23-24 |

| Flexible PCB (Polyimide) | 3.5 at 1 MHz | 0.002 at 1 MHz | 0.2 | 12-14 |

Frequently Asked Questions (FAQ)

-

What is the most commonly used PCB material?

FR-4 is the most commonly used PCB material due to its good electrical and mechanical properties, as well as its cost-effectiveness. It is suitable for a wide range of applications, from consumer electronics to industrial equipment. -

What PCB materials are suitable for high-frequency applications?

For high-frequency applications, materials with low dielectric loss and stable dielectric constants are preferred. Rogers materials, such as RO4003C and RT/duroid 5870, are commonly used in high-frequency applications like wireless communication, radar systems, and microwave circuits. -

What are the advantages of using aluminum PCBs?

Aluminum PCBs offer excellent thermal conductivity, allowing for efficient heat dissipation. This makes them suitable for high-power applications, such as LED lighting and power electronics, where thermal management is critical. Aluminum PCBs also provide good mechanical stability and can serve as a heat sink for components. -

When should I consider using flexible PCBs?

Flexible PCBs are suitable for applications that require conformity to irregular shapes or where space is limited. They are commonly used in wearable devices, medical equipment, automotive electronics, and applications that need the PCB to bend or flex without damaging the circuits. -

How do I select the right PCB material for my application?

When selecting a PCB material, consider the electrical, thermal, and mechanical properties required for your application. Evaluate the material’s dielectric constant, dissipation factor, thermal conductivity, thermal expansion coefficient, and mechanical strength. Also, consider environmental factors such as moisture and chemical resistance. Balance the performance requirements against the cost to choose the most suitable material for your specific application.

Conclusion

The choice of PCB materials is a critical aspect of PCB design and manufacturing. Different materials offer unique properties that cater to specific application requirements. FR-4 is the most widely used material, providing a good balance of electrical, mechanical, and thermal properties. High-performance materials like polyimide and Rogers materials are used in demanding applications that require superior thermal stability, low dielectric loss, and controlled dielectric constants. Aluminum PCBs are ideal for high-power applications that demand efficient thermal management, while flexible PCBs offer conformity and space-saving advantages.

When selecting PCB materials, it is essential to consider the electrical, thermal, mechanical, and environmental requirements of the application. By carefully evaluating these factors and balancing them against cost constraints, designers can choose the most suitable material to ensure optimal performance, reliability, and longevity of the final product.

As technology advances and new applications emerge, the development of advanced PCB materials continues to evolve. Materials with improved properties, such as higher thermal conductivity, lower dielectric loss, and better mechanical stability, are being developed to meet the ever-increasing demands of modern electronics. By staying informed about the latest advancements in PCB materials, designers and manufacturers can make informed decisions and create innovative products that push the boundaries of performance and reliability.

No responses yet