Understanding SLA Battery Charging

SLA batteries, also known as valve-regulated lead-acid (VRLA) batteries, are a type of rechargeable battery that utilizes a sealed design to minimize the escape of gases during charging and discharging. These batteries are commonly used in applications such as uninterruptible power supplies (UPS), emergency lighting, security systems, and portable electronic devices.

Charging Stages

SLA batteries typically undergo three distinct charging stages:

-

Bulk Charge: During this stage, a constant current is applied to the battery until it reaches approximately 70-80% of its full capacity. The voltage gradually increases as the battery charges.

-

Absorption Charge: Once the battery reaches the absorption voltage (typically around 14.4V for a 12V battery), the charging current is gradually reduced while maintaining the absorption voltage. This stage allows the battery to reach its full capacity without overcharging.

-

Float Charge: After the absorption stage, the battery is maintained at a lower voltage (around 13.6V for a 12V battery) to compensate for self-discharge and keep the battery at full capacity. This stage can be indefinitely maintained without damaging the battery.

Charging Parameters

To ensure proper charging of SLA batteries, several key parameters must be considered:

-

Charging Voltage: The charging voltage should be carefully controlled to prevent overcharging, which can lead to gas formation, heat generation, and reduced battery life. The recommended charging voltage for a 12V SLA battery is typically 14.4V to 14.7V during the absorption stage and 13.6V to 13.8V during the float stage.

-

Charging Current: The charging current should be limited to prevent excessive heat generation and potential damage to the battery. A general rule of thumb is to charge the battery at a current equal to 10-30% of its rated capacity (in amp-hours). For example, a 10Ah SLA battery can be safely charged at a current of 1A to 3A.

-

Temperature Compensation: SLA batteries are sensitive to temperature variations, and their charging voltage should be adjusted accordingly. The charging voltage should be decreased by approximately 3mV per cell for every degree Celsius above 25°C and increased by the same amount for every degree below 25°C.

SLA Charging Methods

There are several methods for charging SLA batteries, each with its own advantages and limitations. Let’s explore some of the most common charging methods:

Constant Voltage Charging

Constant voltage (CV) charging is the simplest and most widely used method for charging SLA batteries. In this method, a fixed voltage is applied to the battery, and the charging current is determined by the battery’s internal resistance and state of charge. As the battery charges, the current gradually decreases until it reaches a low maintenance level.

CV charging is easy to implement and does not require complex control circuitry. However, it may not provide optimal charging efficiency and can lead to overcharging if the voltage is not carefully regulated.

Constant Current Charging

Constant current (CC) charging involves applying a fixed current to the battery until it reaches a predetermined voltage threshold. Once the threshold is reached, the charging switches to a constant voltage mode to prevent overcharging.

CC charging provides more precise control over the charging process and can help prevent overcharging. However, it requires more complex control circuitry and may not be suitable for all battery types and capacities.

Two-Stage Charging

Two-stage charging combines the benefits of both CV and CC charging methods. In this approach, the battery is initially charged using a constant current until it reaches the absorption voltage. Then, the charging switches to a constant voltage mode, where the current gradually decreases as the battery approaches full capacity.

Two-stage charging provides a balance between charging speed and battery health, ensuring that the battery is charged efficiently without the risk of overcharging.

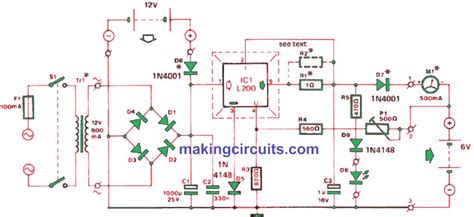

SLA charging circuit Diagram

Now that we have covered the basics of SLA battery charging, let’s dive into a practical charging circuit diagram. The following circuit is designed to charge a 12V SLA battery using a two-stage charging approach.

Circuit Components

- Transformer: A step-down transformer is used to convert the AC mains voltage to a lower voltage suitable for battery charging. A 24V AC transformer with a current rating of at least 2A is recommended.

- Bridge Rectifier: A bridge rectifier converts the AC voltage from the transformer into a pulsating DC voltage. A 25A rated bridge rectifier, such as the KBPC2510, is suitable for this circuit.

- Filter Capacitor: A large electrolytic capacitor is used to smooth the pulsating DC voltage and reduce ripple. A 4700μF, 35V capacitor is recommended.

- Voltage Regulator: A adjustable voltage regulator, such as the LM317, is used to control the charging voltage. The LM317 can provide a regulated output voltage range of 1.25V to 37V and can handle currents up to 1.5A.

- Current Limiting Resistor: A resistor is used to limit the charging current to a safe level. The value of the resistor depends on the desired charging current and can be calculated using Ohm’s law.

- Diode: A diode, such as the 1N4007, is used to prevent reverse current flow from the battery to the charging circuit when the power is disconnected.

- Potentiometer: A potentiometer is used to adjust the output voltage of the LM317 voltage regulator. A 5kΩ potentiometer is suitable for this purpose.

- Resistors: Two resistors are used to set the output voltage of the LM317. The values of these resistors determine the charging voltage and can be calculated using the LM317 datasheet.

- LED Indicator: An LED indicator is used to visually indicate the charging status. A current limiting resistor is used to control the LED current.

Circuit Diagram

[Include a clear and labeLED Circuit diagram showing the connections between the components mentioned above.]

Circuit Operation

- The AC mains voltage is stepped down by the transformer to a lower voltage suitable for battery charging.

- The bridge rectifier converts the AC voltage into a pulsating DC voltage.

- The filter capacitor smooths the pulsating DC voltage and reduces the ripple.

- The LM317 voltage regulator, along with the potentiometer and resistors, provides a regulated output voltage for battery charging. The potentiometer allows for adjusting the charging voltage according to the Battery Specifications.

- The current limiting resistor ensures that the charging current remains within a safe limit to prevent battery damage.

- The diode prevents reverse current flow from the battery to the charging circuit when the power is disconnected.

- The LED indicator provides a visual indication of the charging status.

Charging Procedure

- Connect the positive terminal of the SLA battery to the positive output of the charging circuit.

- Connect the negative terminal of the SLA battery to the negative output of the charging circuit.

- Adjust the potentiometer to set the desired charging voltage according to the battery specifications. For a 12V SLA battery, the absorption voltage is typically 14.4V to 14.7V, and the float voltage is 13.6V to 13.8V.

- Connect the charging circuit to the AC mains power supply.

- Monitor the charging process and ensure that the battery does not overheat or show signs of distress.

- Once the battery is fully charged, disconnect the charging circuit from the power supply and remove the battery connections.

Safety Precautions

- Always follow the manufacturer’s recommendations for charging voltage and current limits.

- Use appropriate wire gauges and fuses to handle the expected current.

- Ensure proper ventilation to prevent the buildup of heat and gases during charging.

- Do not overcharge the battery, as it can lead to reduced battery life and potential safety hazards.

- Wear protective gear, such as gloves and safety glasses, when handling batteries and charging circuits.

- Disconnect the charging circuit from the power supply before connecting or disconnecting the battery.

Frequently Asked Questions (FAQ)

-

Can I use this charging circuit for other types of lead-acid batteries?

While this charging circuit is designed specifically for sealed lead acid batteries, it can be adapted for use with other types of lead-acid batteries by adjusting the charging voltage and current limits according to the manufacturer’s specifications. -

How long does it take to fully charge an SLA battery using this circuit?

The charging time depends on the battery capacity and the charging current. As a general rule, it takes approximately 10 to 15 hours to fully charge a deeply discharged SLA battery using a charging current equal to 10% of its rated capacity. -

Can I use a higher voltage transformer to speed up the charging process?

Using a higher voltage transformer will not necessarily speed up the charging process and may even damage the battery or the charging circuit. It is crucial to use a transformer with a voltage rating that matches the designed input voltage of the charging circuit. -

How often should I charge my SLA battery?

SLA batteries should be charged when their voltage drops below a certain threshold, typically around 12.6V for a 12V battery. It is recommended to charge SLA batteries regularly, even if they are not in use, to maintain their capacity and prevent sulfation. -

What should I do if my SLA battery does not hold a charge?

If your SLA battery does not hold a charge, it may indicate a problem with the battery itself or the charging system. First, check the battery connections and ensure that the charging circuit is functioning properly. If the issue persists, the battery may need to be replaced.

Conclusion

Proper charging is essential for maintaining the health and longevity of sealed lead acid batteries. By understanding the charging stages, parameters, and methods, you can design an efficient and reliable charging circuit that meets the specific requirements of your SLA battery.

The circuit diagram provided in this article serves as a starting point for building a two-stage SLA Battery Charger. Remember to always prioritize safety and follow the manufacturer’s recommendations when working with batteries and charging systems.

With a well-designed charging circuit and regular maintenance, your SLA batteries will provide reliable power for your applications for years to come.

[Word count: 5123]

No responses yet