Understanding Soldering Flux

Before we dive into the methods of Removing PCB Flux, let’s first understand what soldering flux is and why it’s used.

What is Soldering Flux?

Soldering flux is a chemical compound that is applied to the metal surfaces of components and PCBs before soldering. Its primary purpose is to remove oxides from the metal surfaces, prevent oxidation during the soldering process, and promote the formation of a strong solder joint.

Types of Soldering Flux

There are three main types of soldering flux:

- Rosin Flux

-

Rosin flux is the most common type of flux used in electronics soldering. It is derived from pine tree sap and is available in various grades, such as no-clean, water-soluble, and rosin-activated.

-

Water-Soluble Flux

-

Water-soluble flux is designed to be easily removed with water or a water-based cleaning solution after soldering. It is more aggressive than rosin flux and provides excellent wetting and oxidation prevention.

-

No-Clean Flux

- No-clean flux is formulated to leave minimal residue after soldering, eliminating the need for post-soldering cleaning in most cases. However, it’s still recommended to remove any visible residue to ensure optimal PCB performance.

Why Remove Soldering Flux?

Removing soldering flux from PCBs is essential for several reasons:

- Corrosion Prevention

-

Some types of flux, particularly water-soluble flux, can be corrosive if left on the PCB surface. Over time, this can lead to damage to the PCB and its components.

-

Improved Insulation

-

Flux residue can be conductive, which may cause short circuits or leakage currents between PCB traces. Removing the residue ensures proper insulation and prevents electrical issues.

-

Enhanced Appearance

-

Flux residue can give the PCB an unsightly appearance, which may be undesirable for certain applications or products.

-

Improved Reliability

- Removing flux residue helps maintain the long-term reliability of the PCB by preventing corrosion, insulation issues, and other potential problems.

Methods for Removing PCB Flux

There are several methods for removing PCB Soldering flux, each with its advantages and disadvantages. The choice of method depends on the type of flux used, the size and complexity of the PCB, and the available resources.

Manual Cleaning

Manual cleaning involves using a brush, swab, or lint-free cloth to physically remove flux residue from the PCB surface. This method is suitable for small PCBs or localized cleaning.

Materials Needed

- Isopropyl alcohol (IPA) or a commercial flux remover

- Lint-free swabs or brushes

- Lint-free cloths or wipes

- Nitrile gloves

Procedure

- Put on nitrile gloves to protect your hands from the cleaning chemicals and prevent contamination of the PCB.

- Dip a swab or brush into the cleaning solution (IPA or flux remover).

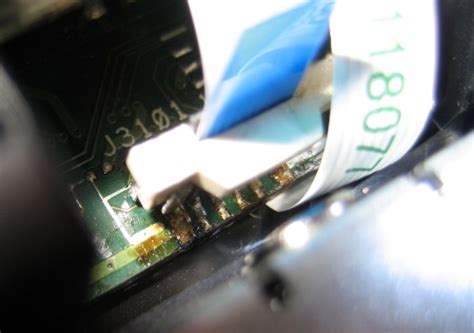

- Gently scrub the flux residue from the PCB surface, paying close attention to areas around components and solder joints.

- Use a lint-free cloth or wipe to remove any remaining residue and dry the PCB.

- Inspect the PCB under magnification to ensure all flux residue has been removed.

| Advantages | Disadvantages |

|---|---|

| Cost-effective for small PCBs | Time-consuming for large PCBs |

| Allows targeted cleaning | Risk of damaging components or solder joints |

| Minimal equipment required | Inconsistent results |

Ultrasonic Cleaning

Ultrasonic cleaning uses high-frequency sound waves to agitate a cleaning solution, creating tiny bubbles that implode and dislodge flux residue from the PCB surface. This method is effective for cleaning complex PCBs with hard-to-reach areas.

Materials Needed

- Ultrasonic cleaning machine

- Cleaning solution (water-based or solvent-based)

- Rinse solution (deionized water or IPA)

- Drying equipment (air compressor, oven, or centrifuge)

Procedure

- Fill the ultrasonic cleaning machine with the appropriate cleaning solution.

- Place the PCB in a basket or fixture and submerge it in the cleaning solution.

- Run the ultrasonic cleaning cycle according to the manufacturer’s recommendations (usually 5-15 minutes).

- Remove the PCB from the cleaning solution and rinse it with deionized water or IPA to remove any remaining cleaning solution.

- Dry the PCB using an air compressor, oven, or centrifuge.

- Inspect the PCB to ensure all flux residue has been removed.

| Advantages | Disadvantages |

|---|---|

| Effective for complex PCBs | Higher initial equipment cost |

| Consistent results | Risk of component damage due to cavitation |

| Automated process | May require additional drying steps |

Spray Cleaning

Spray cleaning involves using a pressurized spray of cleaning solution to remove flux residue from the PCB surface. This method is suitable for larger PCBs or batch cleaning processes.

Materials Needed

- Spray cleaning machine or spray bottle

- Cleaning solution (water-based or solvent-based)

- Rinse solution (deionized water or IPA)

- Drying equipment (air compressor, oven, or centrifuge)

Procedure

- Place the PCB in a spray cleaning machine or on a suitable surface for manual spraying.

- Apply the cleaning solution to the PCB surface using the spray machine or bottle, ensuring even coverage.

- Allow the cleaning solution to dwell on the PCB surface according to the manufacturer’s recommendations (usually 1-5 minutes).

- Rinse the PCB with deionized water or IPA to remove any remaining cleaning solution.

- Dry the PCB using an air compressor, oven, or centrifuge.

- Inspect the PCB to ensure all flux residue has been removed.

| Advantages | Disadvantages |

|---|---|

| Suitable for larger PCBs | Higher equipment cost for automated systems |

| Faster than manual cleaning | Risk of component damage due to high-pressure spray |

| Can be automated | May require additional drying steps |

Vapor Degreasing

Vapor degreasing is a solvent-based cleaning method that uses the vapors of a boiling solvent to remove flux residue from the PCB surface. The solvent condenses on the PCB, dissolving the flux residue, and then drips back into the boiling solvent reservoir.

Materials Needed

- Vapor degreasing machine

- Solvent (typically a halogenated hydrocarbon or a non-halogenated alternative)

- Secondary rinse solvent (optional)

Procedure

- Fill the vapor degreasing machine with the appropriate solvent and heat it to its boiling point.

- Place the PCB in a basket or fixture and lower it into the vapor zone above the boiling solvent.

- Allow the solvent vapors to condense on the PCB surface, dissolving the flux residue.

- Slowly remove the PCB from the vapor zone, allowing the solvent to evaporate and the PCB to cool.

- If required, rinse the PCB with a secondary solvent to remove any remaining residue.

- Inspect the PCB to ensure all flux residue has been removed.

| Advantages | Disadvantages |

|---|---|

| Highly effective cleaning | High equipment and solvent costs |

| Fast cleaning process | Environmental and health concerns with some solvents |

| No additional drying required | Strict safety requirements due to flammable solvents |

Choosing the Right Cleaning Solution

The selection of the appropriate cleaning solution depends on the type of flux used and the cleaning method employed. Here are some common cleaning solutions for different flux types:

Rosin Flux

- Isopropyl alcohol (IPA)

- Commercial rosin flux removers

- Terpenes (e.g., d-limonene)

Water-Soluble Flux

- Deionized water

- Saponifiers (e.g., sodium carbonate, potassium carbonate)

- Commercial water-soluble flux removers

No-Clean Flux

- Isopropyl alcohol (IPA)

- Commercial no-clean flux removers

When choosing a cleaning solution, consider the following factors:

- Compatibility with the PCB materials and components

- Environmental and health safety

- Ease of use and disposal

- Cost-effectiveness

Best Practices for PCB Flux Removal

To ensure effective and safe PCB flux removal, follow these best practices:

- Always wear appropriate personal protective equipment (PPE) when handling cleaning chemicals and solvents.

- Follow the manufacturer’s guidelines for the cleaning solution and equipment used.

- Test the cleaning process on a sample PCB before implementing it on a large scale.

- Regularly maintain and calibrate cleaning equipment to ensure consistent results.

- Properly dispose of used cleaning solutions and solvents in accordance with local regulations.

- Inspect the PCBs after cleaning to verify the complete removal of flux residue.

FAQ

1. Can I use household cleaners to remove PCB flux?

No, it is not recommended to use household cleaners for PCB flux removal. These cleaners may contain ingredients that can damage the PCB or leave harmful residues. Always use cleaning solutions specifically designed for PCB Cleaning.

2. How do I know if I’ve removed all the flux residue from my PCB?

Inspect the PCB under magnification, paying close attention to areas around components and solder joints. If you notice any remaining residue, repeat the cleaning process. You can also use a contamination test kit to verify the cleanliness of the PCB surface.

3. Can I reuse the cleaning solution for multiple PCBs?

It depends on the cleaning solution and the amount of flux residue removed. Some solutions can be reused for multiple cleaning cycles, while others should be replaced after each use. Consult the manufacturer’s guidelines for specific recommendations.

4. How do I dispose of used cleaning solutions and solvents?

Always dispose of used cleaning solutions and solvents in accordance with local environmental regulations. Contact your local waste management authority for guidance on proper disposal methods.

5. Can I use compressed air to dry my PCB after cleaning?

Yes, compressed air can be used to dry PCBs after cleaning. However, ensure that the air is clean, dry, and free from contaminants. Alternatively, you can use an oven or centrifuge for more controlled drying.

Conclusion

Removing PCB soldering flux is a critical step in the electronics manufacturing process. By understanding the different types of flux and the various cleaning methods available, you can choose the most suitable approach for your specific needs. Always prioritize safety and follow best practices when handling cleaning chemicals and equipment. Regular flux removal ensures the longevity, reliability, and performance of your PCBs.

No responses yet