1. Understand the PCB Design Process

Before diving into the specific rules and tips, it’s important to have a solid understanding of the PCB design process. The typical PCB design process consists of the following stages:

- Schematic design

- Component placement

- Routing

- Design rule checks (DRC)

- Gerber File generation

- Manufacturing

Each stage plays a critical role in the overall success of your PCB design. By familiarizing yourself with the process, you can better apply the rules and tips discussed in this article.

2. Adhere to the Manufacturer’s Design Rules

Every PCB Manufacturer has its own set of design rules that specify the minimum requirements for various aspects of the PCB design. These rules cover parameters such as:

- Minimum trace width

- Minimum clearance between traces

- Minimum drill size

- Minimum annular ring

- Minimum solder mask opening

Adhering to these rules is essential to ensure that your PCB can be manufactured without issues. Always obtain the design rules from your chosen manufacturer and incorporate them into your PCB design software’s DRC settings.

3. Use a Consistent Grid System

Establishing a consistent grid system for your PCB layout can help maintain uniformity and make the design process more efficient. A grid system allows you to align components and traces accurately, making the layout more organized and easier to navigate.

When selecting a grid size, consider the following factors:

- Component pitch

- Trace width

- Via size

- Manufacturing capabilities

A common grid size for standard PCBs is 0.1 inches (2.54 mm), but you may need to adjust this based on your specific design requirements and the manufacturer’s capabilities.

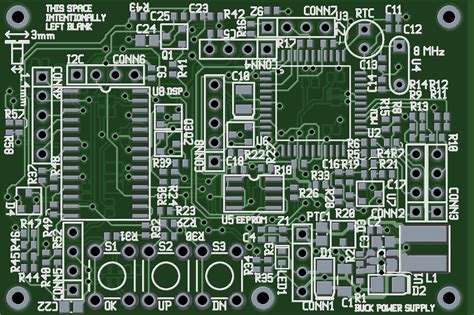

4. Optimize Component Placement

Proper component placement is crucial for achieving a compact, efficient, and manufacturable PCB design. Consider the following tips when placing components on your PCB:

- Group related components together to minimize the length of traces and improve signal integrity.

- Place decoupling capacitors close to the power pins of ICs to reduce noise and improve power stability.

- Orient components in the same direction whenever possible to simplify the assembly process.

- Avoid placing components too close to the edge of the board to prevent damage during handling and assembly.

- Consider the mechanical constraints of the enclosure and ensure that components do not interfere with mounting holes, connectors, or other mechanical features.

5. Route Traces Efficiently

Efficient trace routing is essential for minimizing signal integrity issues, reducing electromagnetic interference (EMI), and improving the overall performance of your PCB. Keep these tips in mind when routing traces:

- Route critical signals first, such as high-speed signals, clock lines, and power traces.

- Use the shortest possible path between components to minimize trace length and reduce signal delay.

- Avoid sharp angles in traces, as they can cause signal reflections and EMI. Use 45-degree angles or curved traces instead.

- Maintain consistent trace width and spacing to ensure Controlled Impedance and minimize crosstalk.

- Use ground planes to provide a low-impedance return path for signals and reduce EMI.

6. Implement Proper Power Distribution

A well-designed power distribution network is essential for ensuring the stability and reliability of your PCB. Follow these guidelines for proper power distribution:

- Use separate power and ground planes for analog and digital sections of the PCB to minimize noise coupling.

- Provide adequate copper pour for power and ground planes to minimize resistance and improve current-carrying capacity.

- Use decoupling capacitors near the power pins of ICs to filter high-frequency noise and maintain power integrity.

- Implement proper power sequencing for ICs that require specific power-up and power-down sequences.

7. Minimize Crosstalk and EMI

Crosstalk and EMI can cause significant issues in PCB designs, leading to signal integrity problems and interference with other electronic devices. To minimize crosstalk and EMI:

- Route critical signals away from each other to reduce coupling.

- Use guard traces or ground shields between sensitive signals to minimize crosstalk.

- Avoid running traces parallel to each other for long distances, as this can increase crosstalk.

- Use differential signaling for high-speed signals to minimize EMI and improve noise immunity.

- Implement proper grounding and shielding techniques to reduce EMI radiation and susceptibility.

8. Consider Signal Integrity

Signal integrity is crucial for ensuring that signals reach their intended destinations without distortion or degradation. To maintain signal integrity:

- Match trace lengths for critical signals, such as clock lines and high-speed buses, to minimize skew and ensure proper timing.

- Terminate long traces with appropriate resistors to prevent reflections and ringing.

- Use appropriate trace widths and spacing to maintain controlled impedance and minimize signal distortion.

- Avoid splitting planes beneath high-speed signals, as this can cause discontinuities and reflections.

9. Implement Proper Thermal Management

Thermal management is essential for ensuring the long-term reliability and performance of your PCB. Consider the following tips for proper thermal management:

- Provide adequate copper pour for power dissipation and heat spreading.

- Use thermal vias to transfer heat from components to the opposite side of the board or to internal power planes.

- Place high-power components away from sensitive components to minimize thermal interaction.

- Consider using thermal interface materials (TIMs) or heatsinks for components with high heat dissipation requirements.

10. Use Appropriate Via Types and Sizes

Vias are essential for connecting traces on different layers of the PCB. When using vias, consider the following:

- Use the appropriate via type for your design, such as through-hole, blind, or Buried vias.

- Minimize the number of vias to reduce manufacturing costs and improve reliability.

- Ensure that via sizes meet the manufacturer’s minimum requirements for drill size and annular ring.

- Use via stitching or via fencing techniques to improve power and ground plane connectivity and reduce EMI.

11. Perform Design Rule Checks (DRC)

Design rule checks (DRC) are automated checks performed by PCB design software to ensure that your design meets the manufacturer’s requirements and adheres to best practices. Always run DRC before finalizing your design and generating manufacturing files.

Common DRC checks include:

- Minimum trace width and spacing

- Minimum drill size and annular ring

- Minimum solder mask opening

- Clearance between components and traces

- Silk screen legibility and clearance

Resolve any DRC violations before proceeding to manufacturing to avoid delays and additional costs.

12. Create Comprehensive Documentation

Comprehensive documentation is essential for ensuring the successful manufacture, assembly, and maintenance of your PCB. Create the following documents to accompany your PCB design:

- Bill of Materials (BOM): A list of all components used in the design, including part numbers, quantities, and suppliers.

- Assembly drawings: Detailed drawings showing the placement and orientation of components on the PCB.

- Fabrication drawings: Drawings that specify the physical dimensions, layer stackup, and materials used in the PCB.

- Schematic diagrams: A graphical representation of the electrical connections and components in the design.

- Test procedures: Instructions for verifying the functionality and performance of the assembled PCB.

Providing clear and accurate documentation can help streamline the manufacturing process and reduce the risk of errors or misinterpretations.

FAQs

-

What is the importance of adhering to the manufacturer’s design rules?

Adhering to the manufacturer’s design rules ensures that your PCB can be manufactured without issues. These rules specify the minimum requirements for various aspects of the PCB design, such as trace width, clearance, and drill size. Violating these rules can lead to manufacturing delays, additional costs, or even non-functional boards. -

How can I minimize crosstalk and EMI in my PCB design?

To minimize crosstalk and EMI, you can follow these practices: - Route critical signals away from each other to reduce coupling.

- Use guard traces or ground shields between sensitive signals.

- Avoid running traces parallel to each other for long distances.

- Use differential signaling for high-speed signals.

-

Implement proper grounding and shielding techniques.

-

What is the purpose of design rule checks (DRC)?

Design rule checks (DRC) are automated checks performed by PCB design software to ensure that your design meets the manufacturer’s requirements and adheres to best practices. DRC helps identify and resolve issues related to trace width, clearance, drill size, and other design aspects before sending the design for manufacturing, thus reducing the risk of delays and additional costs. -

Why is comprehensive documentation important for PCB design?

Comprehensive documentation, including bills of materials (BOM), assembly drawings, fabrication drawings, schematic diagrams, and test procedures, is essential for ensuring the successful manufacture, assembly, and maintenance of your PCB. Clear and accurate documentation helps streamline the manufacturing process, reduces the risk of errors or misinterpretations, and facilitates troubleshooting and repairs if needed. -

What are some thermal management techniques for PCBs?

Some thermal management techniques for PCBs include: - Providing adequate copper pour for power dissipation and heat spreading.

- Using thermal vias to transfer heat from components to the opposite side of the board or to internal power planes.

- Placing high-power components away from sensitive components to minimize thermal interaction.

- Using thermal interface materials (TIMs) or heatsinks for components with high heat dissipation requirements.

| PCB Design Aspect | Best Practices |

|---|---|

| Component Placement | – Group related components together – Place decoupling capacitors close to IC power pins – Orient components in the same direction – Avoid placing components too close to board edges |

| Trace Routing | – Route critical signals first – Use shortest possible path between components – Avoid sharp angles, use 45-degree angles or curves – Maintain consistent trace width and spacing – Use ground planes for low-impedance return path |

| Power Distribution | – Use separate power and ground planes for analog and digital sections – Provide adequate copper pour for power and ground planes – Use decoupling capacitors near IC power pins – Implement proper power sequencing |

| Signal Integrity | – Match trace lengths for critical signals – Terminate long traces with appropriate resistors – Use appropriate trace widths and spacing for controlled impedance – Avoid splitting planes beneath high-speed signals |

By following these 12 PCB design rules and tips, you can create high-quality, reliable, and manufacturable PCBs. Remember to always adhere to the manufacturer’s design rules, use a consistent grid system, optimize component placement, route traces efficiently, implement proper power distribution, minimize crosstalk and EMI, consider signal integrity, implement proper thermal management, use appropriate via types and sizes, perform design rule checks, and create comprehensive documentation. By applying these guidelines to your PCB design process, you can streamline development, reduce the risk of errors, and ensure the successful production of your electronic products.

No responses yet