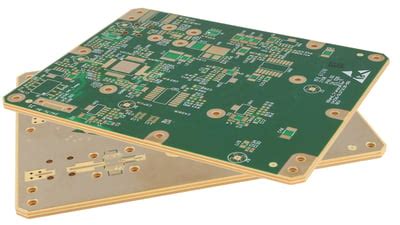

What is PCB Lamination?

PCB lamination is a crucial step in the manufacturing process of printed circuit boards (PCBs). It involves bonding together multiple layers of PCB materials using heat and pressure to create a single, solid board. The lamination process ensures that the layers are properly aligned and that there are no air gaps or voids between them, which could lead to electrical or mechanical issues.

The Importance of PCB Lamination

PCB lamination is essential for several reasons:

- It provides mechanical strength and rigidity to the PCB, allowing it to withstand the stresses of assembly and use.

- It ensures proper electrical insulation between layers, preventing short circuits and signal interference.

- It helps to distribute heat evenly across the board, which is important for thermal management.

The PCB Lamination Process

The PCB lamination process typically involves the following steps:

1. Material Preparation

The first step in PCB lamination is to prepare the materials that will be used to create the board. This includes the copper-clad laminates (CCLs), prepregs, and other materials such as solder masks and silkscreens.

Copper-Clad Laminates (CCLs)

CCLs are the base material for PCBs and consist of a layer of copper foil bonded to a substrate material, such as FR-4 or polyimide. The copper foil is typically available in various thicknesses, ranging from 0.5 oz to 2 oz per square foot.

Prepregs

Prepregs are sheets of partially cured resin that are used to bond the layers of the PCB together. They are typically made from glass fiber cloth impregnated with a heat-curable resin, such as epoxy or polyimide.

2. Layer Stacking

Once the materials have been prepared, the next step is to stack the layers of the PCB in the correct order. This typically involves alternating layers of CCLs and prepregs, with the outer layers being CCLs to provide a surface for the copper traces.

The number of layers in a PCB can vary depending on the complexity of the design and the requirements of the application. Simple designs may only require two layers, while more complex designs can have up to 50 layers or more.

3. Lamination

After the layers have been stacked, they are placed in a lamination press. The press applies heat and pressure to the stack, causing the prepregs to melt and flow between the layers, bonding them together.

The lamination process typically involves the following steps:

- The stack is placed between two metal plates called “platens.”

- The platens are heated to a temperature of around 180-200°C (356-392°F).

- Pressure is applied to the stack, typically in the range of 200-400 psi.

- The stack is held at this temperature and pressure for a specific time, usually around 1-2 hours.

- The stack is then cooled while maintaining pressure to ensure that the layers remain bonded together.

4. Finishing

After the lamination process is complete, the PCB undergoes several finishing steps to prepare it for assembly. These steps may include:

- Drilling holes for through-hole components and vias

- Applying solder mask and silkscreen

- Surface finishing, such as HASL, ENIG, or OSP

Factors Affecting PCB Lamination

Several factors can affect the quality and reliability of the PCB lamination process, including:

Material Selection

The choice of materials used in the PCB, such as the type of CCL and prepreg, can have a significant impact on the lamination process. Different materials have different thermal and mechanical properties, which can affect the bonding strength and durability of the final board.

Lamination Parameters

The lamination parameters, such as temperature, pressure, and time, must be carefully controlled to ensure a successful lamination process. If the temperature or pressure is too low, the layers may not bond properly, while if they are too high, the materials may degrade or warp.

Cleanliness

Cleanliness is critical in the PCB lamination process, as any contaminants or debris on the surface of the layers can lead to voids or delamination. It is important to ensure that the materials and equipment used in the lamination process are clean and free from contaminants.

PCB Lamination Techniques

There are several different techniques that can be used for PCB lamination, each with its own advantages and disadvantages.

Vacuum Lamination

Vacuum lamination involves placing the PCB stack in a vacuum chamber before applying heat and pressure. The vacuum helps to remove any air or moisture from between the layers, reducing the risk of voids or delamination.

Hydraulic Lamination

Hydraulic lamination uses a hydraulic press to apply pressure to the PCB stack. This technique allows for more precise control over the pressure applied to the stack, which can help to ensure a more consistent lamination process.

Autoclave Lamination

Autoclave lamination involves placing the PCB stack in a pressurized vessel filled with heated nitrogen gas. The high pressure and temperature help to ensure a strong bond between the layers, while the nitrogen gas helps to prevent oxidation of the copper layers.

Challenges in PCB Lamination

Despite advances in PCB lamination technology, there are still several challenges that can arise during the lamination process.

Delamination

Delamination is one of the most common issues in PCB lamination and occurs when the layers of the PCB separate or peel apart. This can be caused by a variety of factors, such as poor material selection, insufficient pressure or temperature during lamination, or contamination of the layers.

Warpage

Warpage is another common issue in PCB lamination and occurs when the board bends or twists out of shape. This can be caused by uneven heating or cooling during the lamination process, or by differences in the thermal expansion coefficients of the materials used in the board.

Voids

Voids are small air pockets that can form between the layers of the PCB during lamination. These voids can lead to electrical or mechanical issues and can be caused by poor material preparation, insufficient pressure during lamination, or contamination of the layers.

Conclusion

PCB lamination is a critical step in the manufacturing process of printed circuit boards, ensuring that the layers of the board are properly bonded together to create a single, solid unit. The lamination process involves careful material selection, layer stacking, and the application of heat and pressure to bond the layers together.

While there are several different techniques that can be used for PCB lamination, each with its own advantages and disadvantages, the key to a successful lamination process is careful control of the lamination parameters and ensuring the cleanliness and quality of the materials used.

Despite advances in PCB lamination technology, there are still several challenges that can arise during the lamination process, such as delamination, warpage, and voids. By understanding these challenges and taking steps to mitigate them, PCB Manufacturers can ensure the highest quality and reliability of their products.

Frequently Asked Questions (FAQ)

1. What is the difference between CCLs and prepregs in PCB lamination?

CCLs (copper-clad laminates) are the base material for PCBs and consist of a layer of copper foil bonded to a substrate material, such as FR-4 or polyimide. Prepregs, on the other hand, are sheets of partially cured resin that are used to bond the layers of the PCB together during the lamination process.

2. What is the purpose of applying pressure during PCB lamination?

Applying pressure during PCB lamination helps to ensure that the layers of the board are properly bonded together and that there are no air gaps or voids between them. The pressure helps to compress the layers and force the prepreg to flow between them, creating a strong and reliable bond.

3. What is the typical temperature and pressure used in PCB lamination?

The typical temperature used in PCB lamination is around 180-200°C (356-392°F), while the typical pressure is in the range of 200-400 psi. These parameters can vary depending on the specific materials and techniques used in the lamination process.

4. What are some common issues that can arise during PCB lamination?

Some common issues that can arise during PCB lamination include delamination (separation of the layers), warpage (bending or twisting of the board), and voids (small air pockets between the layers). These issues can be caused by a variety of factors, such as poor material selection, insufficient pressure or temperature during lamination, or contamination of the layers.

5. How can PCB manufacturers ensure the highest quality and reliability of their products through the lamination process?

PCB manufacturers can ensure the highest quality and reliability of their products through the lamination process by carefully controlling the lamination parameters, such as temperature and pressure, and ensuring the cleanliness and quality of the materials used. They can also use advanced techniques such as vacuum lamination or autoclave lamination to reduce the risk of issues such as delamination or voids. Additionally, regular testing and inspection of the laminated boards can help to identify and address any issues before they become more serious problems.

No responses yet