Introduction to PCB Soldering

Printed circuit board (PCB) soldering is the process of joining electronic components to a PCB using solder, a fusible metal alloy. Proper soldering technique is essential for creating reliable electrical connections and a functional finished product. However, hand soldering PCBs can present various challenges and potential issues.

In this article, we will explore 10 common PCB hand soldering problems and provide solutions to help you achieve optimal results. By understanding these issues and implementing the appropriate techniques, you can improve your soldering skills and ensure the quality and longevity of your PCB assemblies.

1. Cold Solder Joints

What are cold solder joints?

Cold solder joints occur when the solder does not melt completely, resulting in a weak and unreliable connection. These joints appear dull, grainy, or lumpy and can cause intermittent electrical issues or complete failure of the circuit.

Causes of cold solder joints

- Insufficient heat applied to the joint

- Inadequate flux or contaminated surfaces

- Moving the component or PCB during soldering

- Using the wrong type of solder

Solutions

- Ensure your soldering iron is set to the appropriate temperature for the solder type and PCB materials.

- Clean the component leads and PCB pads thoroughly before soldering.

- Use a high-quality flux to promote proper solder flow and adhesion.

- Keep the component and PCB stable during the soldering process.

- Select the appropriate solder alloy for your application.

2. Bridging

What is bridging?

Bridging occurs when excess solder accidentally connects two or more adjacent pads or traces, creating an unintended short circuit. This can lead to malfunctions or damage to the components.

Causes of bridging

- Applying too much solder

- Using a soldering iron tip that is too large for the job

- Inadequate spacing between pads or traces on the PCB

Solutions

- Use the appropriate amount of solder for the joint size.

- Select a soldering iron tip that matches the size of the pads or traces.

- Ensure proper spacing between pads and traces during PCB design.

- If bridging occurs, use solder wick or a desoldering pump to remove the excess solder.

3. Overheating Components

What is component overheating?

Overheating occurs when excessive heat is applied to a component during soldering, potentially causing damage or altering its performance characteristics.

Causes of component overheating

- Applying the soldering iron for too long

- Using an excessively high soldering iron temperature

- Insufficient heat sinking or thermal management

Solutions

- Limit soldering time to the minimum required for a good joint.

- Adjust the soldering iron temperature based on the component’s heat sensitivity.

- Use heat sinks or thermal clamps to protect heat-sensitive components.

- Allow components to cool down between soldering operations.

4. Insufficient Wetting

What is insufficient wetting?

Insufficient wetting occurs when the solder does not flow properly onto the component lead or PCB pad, resulting in a weak or incomplete connection.

Causes of insufficient wetting

- Dirty or oxidized component leads or PCB pads

- Inadequate flux or incorrect flux type

- Incorrect soldering iron temperature

- Insufficient solder application

Solutions

- Clean the component leads and PCB pads before soldering.

- Use an appropriate flux to promote solder flow and adhesion.

- Adjust the soldering iron temperature to match the solder and PCB materials.

- Apply enough solder to create a proper joint, but avoid excess.

5. Lifted Pads

What are lifted pads?

Lifted pads occur when the copper pad on the PCB separates from the substrate during the soldering process, causing a break in the electrical connection.

Causes of lifted pads

- Excessive heat applied to the pad

- Inadequate adhesion between the copper pad and PCB substrate

- Mechanical stress during component removal or rework

Solutions

- Control the soldering iron temperature and duration to avoid overheating the pad.

- Ensure proper adhesion between the copper pad and PCB substrate during manufacturing.

- Use care when removing or replacing components to minimize mechanical stress on the pads.

- If a lifted pad occurs, use a jumper wire to restore the electrical connection.

6. Solder Balls

What are solder balls?

Solder balls are small, spherical pieces of solder that can form during the soldering process and may cause short circuits if they come into contact with other components or traces.

Causes of solder balls

- Excessive solder application

- High soldering iron temperature

- Inadequate flux or contaminated surfaces

Solutions

- Apply the appropriate amount of solder for the joint size.

- Adjust the soldering iron temperature to prevent solder spattering.

- Use a high-quality flux and clean the surfaces before soldering.

- Inspect the PCB after soldering and remove any solder balls using tweezers or a solder vacuum.

7. Tombstoning

What is tombstoning?

Tombstoning, also known as drawbridging, occurs when a surface-mount component stands up on one end due to uneven heating or solder surface tension, resulting in an open circuit.

Causes of tombstoning

- Uneven heating of the component pads

- Imbalanced solder volumes on the pads

- Incorrect component placement or alignment

Solutions

- Apply heat evenly to both component pads simultaneously.

- Ensure equal amounts of solder on the pads.

- Use a soldering iron tip appropriate for the component size.

- Verify proper component placement and alignment before soldering.

8. Flux Residue

What is flux residue?

Flux residue is the remaining non-conductive material left on the PCB after the soldering process. While some flux residue is acceptable, excessive amounts can cause issues such as poor appearance, reduced insulation resistance, or corrosion.

Causes of excessive flux residue

- Using too much flux

- Selecting an inappropriate flux type for the application

- Inadequate cleaning after soldering

Solutions

- Apply flux sparingly, using only the amount necessary for proper solder flow.

- Choose a flux type that is compatible with your PCB materials and cleaning process.

- Clean the PCB thoroughly after soldering, using the appropriate solvents or cleaning agents.

9. Inadequate Fillets

What are inadequate fillets?

A fillet is the concave meniscus of solder that forms between the component lead and the PCB pad. Inadequate fillets are characterized by insufficient solder coverage or poor wetting, leading to weak mechanical and electrical connections.

Causes of inadequate fillets

- Insufficient solder application

- Poor wetting due to contamination or oxidation

- Incorrect soldering iron temperature or technique

Solutions

- Apply enough solder to create a proper fillet, ensuring good coverage of the lead and pad.

- Clean the component leads and PCB pads before soldering to promote proper wetting.

- Use the appropriate soldering iron temperature and technique for the solder type and PCB materials.

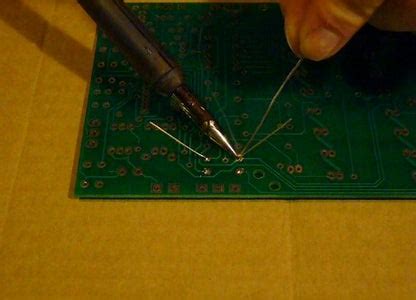

10. Whiskers

What are whiskers?

Whiskers are thin, hair-like metallic growths that can develop on soldered surfaces over time, particularly on tin-based solder joints. These whiskers can cause short circuits and reliability issues.

Causes of whiskers

- Stress in the solder joint due to thermal cycling or mechanical strain

- Impurities in the solder alloy

- Exposure to certain environmental conditions (e.g., high humidity, temperature fluctuations)

Solutions

- Use lead-based or lead-free solder alloys that are less prone to whisker growth.

- Minimize stress on the solder joints through proper PCB design and component selection.

- Control environmental factors, such as humidity and temperature, to reduce the risk of whisker formation.

- Apply conformal coatings or encapsulants to protect the solder joints from environmental factors.

Frequently Asked Questions (FAQ)

1. What is the ideal soldering iron temperature for PCB soldering?

The ideal soldering iron temperature depends on the type of solder and the PCB materials. For leaded solder, a temperature range of 315-370°C (600-700°F) is typically used. For lead-free solder, a higher temperature range of 370-425°C (700-800°F) is recommended. Always refer to the solder manufacturer’s guidelines and the PCB specifications for the most accurate temperature settings.

2. How do I choose the right solder for my PCB project?

When selecting solder for your PCB project, consider the following factors:

- Alloy composition (e.g., tin-lead, lead-free)

- Solder diameter (e.g., 0.5mm, 0.8mm, 1.0mm)

- Flux core type (e.g., rosin, no-clean, water-soluble)

Choose a solder alloy that is compatible with your PCB materials and meets any regulatory requirements (e.g., RoHS Compliance). The solder diameter should be appropriate for the size of the components and pads. The flux core type should be selected based on your cleaning process and the desired level of residue after soldering.

3. What are some essential tools for PCB hand soldering?

Essential tools for PCB hand soldering include:

- Soldering iron with adjustable temperature control

- Soldering iron tips of various sizes and shapes

- Solder (wire or paste)

- Flux (if not using flux-cored solder)

- Solder wick or desoldering pump

- Tweezers or needle-nose pliers

- Side cutters

- PCB Holder or vise

- Magnifying lens or microscope

- ESD-safe mat and wrist strap

Having the right tools and keeping them in good condition will help you achieve better soldering results and work more efficiently.

4. How do I clean my PCB after soldering?

Cleaning your PCB after soldering is essential for removing flux residue and ensuring a professional appearance. The cleaning method depends on the type of flux used:

- Rosin flux: Use isopropyl alcohol (IPA) and a soft brush to remove the residue. Alternatively, you can use a commercial flux cleaner designed for rosin-based fluxes.

- Water-soluble flux: Clean the PCB with distilled water and a soft brush. You may also use a commercial flux cleaner designed for water-soluble fluxes.

- No-clean flux: Minimal cleaning is required, as the flux residue is designed to be non-conductive and non-corrosive. However, you may still clean the PCB with IPA for a better appearance.

Always follow the manufacturer’s guidelines for cleaning agents and methods compatible with your PCB materials and components.

5. How can I improve my PCB soldering skills?

To improve your PCB soldering skills, consider the following tips:

- Practice regularly on scrap PCBs or practice kits to develop muscle memory and technique.

- Watch tutorial videos and read guides from experienced professionals to learn best practices and tips.

- Invest in high-quality tools, such as a reliable soldering iron with adjustable temperature control and well-maintained tips.

- Pay attention to detail, and work on developing a steady hand and consistent technique.

- Seek feedback from experienced peers or join online communities to share your work and receive constructive criticism.

- Experiment with different solder alloys, flux types, and techniques to find what works best for your projects.

- Take breaks and maintain good posture to avoid fatigue and strain during lengthy soldering sessions.

Remember that mastering PCB soldering takes time, patience, and dedication. With consistent practice and a willingness to learn, you can improve your skills and achieve professional-quality results.

Conclusion

PCB hand soldering can present various challenges, but by understanding common problems and implementing the appropriate solutions, you can achieve reliable and professional results. Remember to select the right tools and materials, maintain a clean workspace, and practice proper technique.

By addressing issues such as cold solder joints, bridging, overheating, insufficient wetting, lifted pads, solder balls, tombstoning, flux residue, inadequate fillets, and whiskers, you can significantly improve the quality and longevity of your PCB assemblies.

Regularly practicing and staying up-to-date with best practices will help you refine your skills and tackle even the most complex PCB soldering projects with confidence.

| Problem | Causes | Solutions |

|---|---|---|

| Cold Solder Joints | – Insufficient heat – Inadequate flux – Moving components – Wrong solder type |

– Adjust soldering iron temperature – Clean surfaces and use proper flux – Keep components stable – Select appropriate solder alloy |

| Bridging | – Excess solder – Oversized iron tip – Inadequate pad spacing |

– Use appropriate solder amount – Match tip size to pads/traces – Ensure proper pad spacing in design |

| Overheating Components | – Prolonged soldering time – High iron temperature – Insufficient heat sinking |

– Limit soldering time – Adjust temperature for component sensitivity – Use heat sinks or thermal clamps |

| Insufficient Wetting | – Dirty/oxidized surfaces – Inadequate/incorrect flux – Incorrect iron temperature – Insufficient solder |

– Clean surfaces before soldering – Use appropriate flux type – Adjust iron temperature for solder and PCB – Apply enough solder for proper joint |

| Lifted Pads | – Excessive pad heating – Poor pad adhesion – Mechanical stress during rework |

– Control iron temperature and duration – Ensure proper pad adhesion in manufacturing – Minimize stress during component removal/replacement |

No responses yet