What You’ll Need for PCB Soldering

Before starting your PCB soldering project, make sure you have the following tools and materials:

| Tools | Materials |

|---|---|

| Soldering iron | Solder (lead or lead-free) |

| Soldering iron stand | Solder wick (desoldering braid) |

| Sponge or brass wool | Flux |

| Tweezers | Isopropyl alcohol |

| Wire cutters | PCB |

| Multimeter | Electronic components |

| Safety glasses | PCB Holder (optional) |

Choosing the Right Soldering Iron

A soldering iron is the most important tool for PCB soldering. When selecting a soldering iron, consider the following factors:

- Wattage: For PCB soldering, a soldering iron with 20-50 watts is suitable.

- Temperature control: Adjustable temperature control allows you to set the optimal temperature for the solder and components you are using.

- Tip size and shape: Choose a tip that matches the size of the components and pads on your PCB. Common tip shapes include chisel, conical, and fine point.

Preparing Your Workspace for PCB Soldering

Having a clean, well-organized workspace is crucial for successful PCB soldering. Follow these steps to prepare your workspace:

- Clean your work surface and ensure it is free of clutter.

- Set up your soldering iron stand and sponge or brass wool for cleaning the iron tip.

- Place your PCB on a PCB holder or a stable, non-flammable surface.

- Organize your electronic components and tools within easy reach.

- Ensure proper ventilation to avoid inhaling solder fumes.

PCB Soldering Techniques

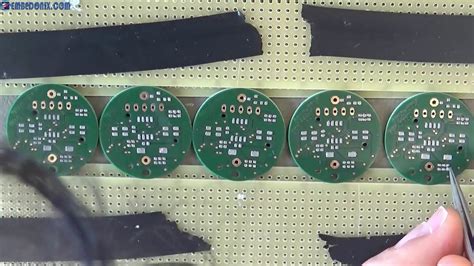

There are two main techniques for soldering components to a PCB: through-hole soldering and surface-mount soldering.

Through-Hole Soldering

Through-hole soldering involves inserting component leads through pre-drilled holes in the PCB and soldering them on the opposite side. Follow these steps for through-hole soldering:

- Insert the component leads through the corresponding holes in the PCB.

- Bend the leads slightly outward to hold the component in place.

- Heat the soldering iron to the appropriate temperature (typically between 315°C and 400°C).

- Clean the soldering iron tip on the sponge or brass wool.

- Apply a small amount of solder to the iron tip to create a heat bridge.

- Touch the iron tip to the component lead and the PCB pad simultaneously.

- Feed solder into the joint, allowing it to melt and flow around the lead and pad.

- Remove the solder and the iron tip, and let the joint cool for a few seconds.

- Trim the excess component leads with wire cutters.

Surface-Mount Soldering

Surface-mount soldering involves attaching components directly to the surface of the PCB without using through-holes. SMD (Surface Mount Device) components are smaller and require more precision when soldering. Follow these steps for surface-mount soldering:

- Apply a small amount of solder paste or flux to the PCB pads.

- Place the SMD component on the pads using tweezers, ensuring proper alignment.

- Heat the soldering iron to the appropriate temperature (typically between 315°C and 400°C).

- Clean the soldering iron tip on the sponge or brass wool.

- Touch the iron tip to the component lead and the PCB pad simultaneously.

- Feed a small amount of solder into the joint, allowing it to melt and flow around the lead and pad.

- Remove the solder and the iron tip, and let the joint cool for a few seconds.

- Repeat the process for the remaining leads.

Inspecting and Testing Your Soldered PCB

After soldering all the components, it’s essential to inspect and test your work to ensure proper connections and functionality.

Visual Inspection

Perform a visual inspection of the soldered joints using a magnifying glass or microscope. Look for the following:

- Shiny, concave solder joints

- Solder covering the entire pad and component lead

- No excess solder bridging adjacent pads or leads

- No cold joints (dull, cracked, or lumpy solder joints)

Continuity Testing

Use a multimeter to test the continuity of the soldered connections. Set the multimeter to the continuity or resistance mode and follow these steps:

- Place one multimeter probe on a component lead.

- Place the other probe on the corresponding PCB pad.

- The multimeter should indicate continuity (a beep or low resistance reading).

- Repeat the process for all soldered connections.

Functional Testing

Power on the PCB and test its functionality according to the circuit’s intended purpose. If the PCB doesn’t function as expected, recheck your solder joints and component placement for any errors.

Common PCB Soldering Mistakes and How to Avoid Them

To ensure a successful PCB soldering project, avoid these common mistakes:

-

Using the wrong soldering iron temperature: Too low a temperature can result in cold joints, while too high a temperature can damage components. Refer to the solder and component specifications for the optimal temperature range.

-

Applying too much or too little solder: Excessive solder can create bridges between pads, while insufficient solder can lead to weak joints. Apply just enough solder to cover the pad and component lead.

-

Soldering for too long: Prolonged heat exposure can damage components and lift PCB pads. Solder quickly and efficiently, removing the iron as soon as the solder flows properly.

-

Not cleaning the soldering iron tip: A dirty or oxidized tip can hinder heat transfer and cause poor solder joints. Clean the tip frequently on a damp sponge or brass wool.

-

Forgetting to apply flux: Flux helps the solder flow evenly and prevents oxidation. Apply a small amount of flux to the pads before soldering, especially for surface-mount components.

FAQ

- What is the difference between lead and lead-free solder?

-

Lead solder contains a mixture of tin and lead, while lead-free solder is typically made of tin, copper, and silver. Lead-free solder has a higher melting point and requires slightly different soldering techniques. Choose lead-free solder for safer and more environmentally-friendly electronics assembly.

-

How do I remove excess solder from a PCB?

-

To remove excess solder, use desoldering braid (solder wick). Place the braid on the excess solder, heat it with the soldering iron, and the solder will wick up into the braid. Alternatively, you can use a desoldering pump (solder sucker) to suck up the molten solder.

-

Can I reuse a PCB after desoldering components?

-

Yes, you can reuse a PCB after desoldering components, provided that the PCB pads and traces are not damaged during the desoldering process. Clean the pads thoroughly with isopropyl alcohol and inspect them for any lifting or damage before soldering new components.

-

How do I prevent static damage to sensitive electronic components?

-

To prevent static damage, wear an anti-static wrist strap connected to a grounded point, or work on an anti-static mat. Avoid touching component leads or PCB pads directly, and hold components by their edges or packaging.

-

What should I do if I accidentally create a solder bridge between two pads?

- If you create a solder bridge, use desoldering braid to remove the excess solder. Place the braid over the bridge, heat it with the soldering iron, and the solder will wick up into the braid. If the bridge persists, you may need to use a fine-tipped soldering iron to carefully remove the excess solder.

By following this guide and practicing proper PCB soldering techniques, you’ll be well on your way to creating professional-quality electronic assemblies. Remember to always prioritize safety, work in a well-ventilated area, and take your time to ensure the best possible results.

No responses yet