Introduction to Gold-Plated Connectors

Gold-plated connectors are a type of electrical connector that features a thin layer of gold plating over the contact surfaces. The gold plating provides several benefits, including improved conductivity, corrosion resistance, and durability. These connectors are widely used in various industries, such as telecommunications, aerospace, automotive, and consumer electronics, where reliable and high-quality electrical connections are essential.

Advantages of Gold-Plated Connectors

- Enhanced conductivity: Gold is an excellent conductor of electricity, which ensures minimal signal loss and optimal performance in high-frequency applications.

- Corrosion resistance: Gold is highly resistant to corrosion, oxidation, and tarnishing, making gold-plated connectors suitable for use in harsh environments.

- Durability: Gold-plated connectors can withstand numerous mating cycles without significant wear, ensuring a long lifespan and reliable performance.

- Low contact resistance: The gold plating helps maintain low contact resistance, which is crucial for sensitive electronic devices and applications.

- Compatibility: Gold-plated connectors are compatible with a wide range of mating surfaces, including other gold-plated connectors and bare metal contacts.

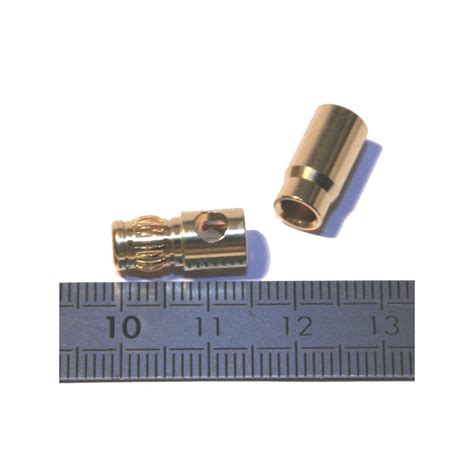

Types of Gold-Plated Connectors

There are several types of gold-plated connectors available, each designed for specific applications and requirements. Some common types include:

1. Edge Connectors

Gold-Plated Edge Connectors are used to connect printed circuit boards (PCBs) to other components or systems. They feature a row of gold-plated contacts along one edge of the PCB, which mates with a corresponding socket or connector. Edge connectors are commonly used in computer memory modules, expansion cards, and various industrial applications.

2. USB Connectors

USB (Universal Serial Bus) connectors are widely used in consumer electronics for data transfer and charging purposes. Gold-plated USB connectors ensure reliable connections and protect against corrosion, which is especially important for frequently used devices such as smartphones, tablets, and laptops.

3. HDMI Connectors

HDMI (High-Definition Multimedia Interface) connectors are used to transmit high-quality digital video and audio signals between devices. Gold-plated HDMI connectors provide optimal signal integrity and resistance to corrosion, ensuring a clear and stable connection for home entertainment systems, gaming consoles, and professional A/V equipment.

4. RF Connectors

RF (Radio Frequency) connectors are used in wireless communication systems, such as antennas, transmitters, and receivers. Gold-plated RF connectors offer excellent electrical conductivity and low signal loss, which is crucial for maintaining signal quality and minimizing interference in high-frequency applications.

Manufacturing Process of Gold-Plated Connectors

The manufacturing process of gold-plated connectors involves several steps to ensure high quality and reliability:

- Base metal selection: The base metal for the connector, typically copper or brass, is selected based on its electrical and mechanical properties.

- Stamping or machining: The base metal is stamped or machined into the desired connector shape and size.

- Pre-plating processes: The connectors undergo cleaning, degreasing, and activation to prepare the surface for plating.

- Nickel plating: A layer of nickel is plated onto the base metal to provide a smooth, uniform surface and improve adhesion for the gold plating.

- Gold plating: The connectors are plated with a thin layer of gold using electroplating or other plating methods. The thickness of the gold plating depends on the specific application and requirements.

- Post-plating processes: The gold-plated connectors are rinsed, dried, and inspected for quality control.

- Assembly and packaging: The connectors are assembled into their final form, such as edge connectors or USB connectors, and packaged for distribution.

| Step | Process | Purpose |

|---|---|---|

| 1 | Base metal selection | Choose material with suitable electrical and mechanical properties |

| 2 | Stamping or machining | Shape the base metal into the desired connector form |

| 3 | Pre-plating processes | Clean and prepare the surface for plating |

| 4 | Nickel plating | Provide a smooth, uniform surface and improve gold adhesion |

| 5 | Gold plating | Deposit a thin layer of gold onto the connector surface |

| 6 | Post-plating processes | Rinse, dry, and inspect the gold-plated connectors |

| 7 | Assembly and packaging | Assemble connectors into final form and package for distribution |

Gold Plating Techniques

Several gold plating techniques are used in the manufacturing of gold-plated connectors, each with its advantages and limitations:

1. Electroplating

Electroplating is the most common method for gold plating connectors. In this process, the connector is submerged in a gold electrolyte solution, and an electrical current is applied. The gold ions in the solution are attracted to the connector surface, forming a thin, uniform layer of gold. Electroplating offers good control over the plating thickness and can be easily automated for high-volume production.

2. Electroless Plating

Electroless plating, also known as autocatalytic plating, is a chemical process that deposits a layer of gold onto the connector surface without the use of an electrical current. This method involves immersing the connector in a gold plating solution containing a reducing agent, which causes the gold to deposit onto the surface. Electroless plating is suitable for complex shapes and provides a more uniform coating than electroplating.

3. Immersion Plating

Immersion plating is a simple process in which the connector is dipped into a gold plating solution, and a thin layer of gold is deposited onto the surface through a chemical exchange reaction. This method is less common for gold plating connectors due to its limited thickness control and slower plating rate compared to electroplating and electroless plating.

| Plating Technique | Advantages | Limitations |

|---|---|---|

| Electroplating | Good thickness control, easily automated | Requires electrical current, may have uneven coating on complex shapes |

| Electroless Plating | Uniform coating, suitable for complex shapes | Slower plating rate, more expensive than electroplating |

| Immersion Plating | Simple process, no electrical current required | Limited thickness control, slower plating rate |

Gold Plating Thickness and Specifications

The thickness of the gold plating on connectors is a critical factor in determining their performance and durability. The appropriate plating thickness depends on the specific application and the requirements for wear resistance, corrosion protection, and electrical conductivity.

Common gold plating thicknesses for connectors include:

- Flash gold: 0.08-0.20 microinches (2-5 nanometers)

- Thin gold: 0.20-1.18 microinches (5-30 nanometers)

- Thick gold: 1.18-3.94 microinches (30-100 nanometers)

Thicker gold plating generally provides better wear resistance and corrosion protection, but it also increases the cost of the connector. Thin gold plating is often sufficient for most applications, while flash gold is used for decorative purposes or as a protective layer for other plating materials.

Several industry standards and specifications govern the gold plating of connectors, ensuring consistency and reliability across different manufacturers:

- MIL-DTL-45204: A military specification for gold plating of electrical and electronic components

- ASTM B488: A standard specification for electrodeposited coatings of gold for engineering uses

- IPC-4552: A standard for electroplated gold on copper for printed circuit boards and related applications

Factors Affecting Gold-Plated Connector Performance

Several factors can impact the performance and reliability of gold-plated connectors:

- Plating thickness: As mentioned earlier, the thickness of the gold plating plays a crucial role in determining the connector’s wear resistance, corrosion protection, and electrical conductivity.

- Base metal: The choice of base metal, such as copper or brass, can affect the connector’s mechanical strength, electrical properties, and compatibility with the gold plating process.

- Plating quality: The uniformity and consistency of the gold plating across the connector surface can impact its performance. Defects such as pinholes, nodules, or cracks can lead to reduced corrosion resistance and electrical conductivity.

- Environmental conditions: Gold-plated connectors may be exposed to various environmental factors, such as temperature fluctuations, humidity, and chemical contaminants, which can degrade the plating over time.

- Mating cycles: The number of times a connector is mated and unmated can affect its durability and performance. Repeated mating cycles can cause wear on the gold plating, leading to reduced contact area and increased contact resistance.

To ensure optimal performance and reliability, it is essential to select gold-plated connectors that are designed and manufactured to meet the specific requirements of the application and to follow proper handling and maintenance practices.

Applications of Gold-Plated Connectors

Gold-plated connectors find use in a wide range of industries and applications, where reliable and high-quality electrical connections are essential. Some common applications include:

- Telecommunications: Gold-plated connectors are used in telecom equipment, such as switchgear, routers, and base stations, to ensure reliable signal transmission and protection against corrosion.

- Aerospace: In aerospace applications, gold-plated connectors are used in avionics, satellite systems, and other critical components that require high reliability and resistance to harsh environments.

- Automotive: Gold-plated connectors are used in various automotive electronic systems, such as engine control units, sensors, and infotainment systems, to ensure stable and reliable connections in demanding conditions.

- Consumer electronics: Many consumer electronic devices, such as smartphones, laptops, and gaming consoles, use gold-plated connectors for USB, HDMI, and other interfaces to provide optimal signal quality and durability.

- Medical devices: Gold-plated connectors are used in medical equipment, such as patient monitors, diagnostic devices, and surgical instruments, where reliable and corrosion-resistant connections are crucial for patient safety and device performance.

- Industrial automation: In industrial automation systems, gold-plated connectors are used in sensors, controllers, and communication interfaces to ensure reliable data transmission and protection against harsh industrial environments.

Frequently Asked Questions (FAQ)

1. What are the benefits of using gold-plated connectors?

Gold-plated connectors offer several benefits, including:

– Enhanced electrical conductivity

– Corrosion resistance

– Durability and wear resistance

– Low contact resistance

– Compatibility with various mating surfaces

2. How do I choose the right gold plating thickness for my application?

The choice of gold plating thickness depends on the specific requirements of your application. Factors to consider include the desired level of wear resistance, corrosion protection, and electrical conductivity, as well as the cost constraints. Consult the relevant industry standards and specifications, such as MIL-DTL-45204 or IPC-4552, for guidance on selecting the appropriate plating thickness.

3. Can gold-plated connectors be used in high-temperature applications?

Yes, gold-plated connectors can be used in high-temperature applications, as gold remains stable and conductive at elevated temperatures. However, it is important to ensure that the base metal and other materials used in the connector are also suitable for high-temperature use.

4. How do I maintain and clean gold-plated connectors?

To maintain the performance and longevity of gold-plated connectors, follow these tips:

– Handle connectors with care to avoid scratches or damage to the plating

– Use dust covers or caps to protect connectors when not in use

– Clean connectors periodically with a soft, lint-free cloth and isopropyl alcohol to remove dirt and contaminants

– Avoid using abrasive materials or harsh chemicals that can damage the gold plating

5. Are gold-plated connectors more expensive than other connector types?

Yes, gold-plated connectors are generally more expensive than connectors with other plating materials, such as tin or nickel. This is due to the higher cost of gold and the additional processing steps required for gold plating. However, the superior performance and reliability of gold-plated connectors often justify the increased cost in applications where high-quality electrical connections are critical.

Conclusion

Gold-plated connectors are essential components in a wide range of industries and applications, offering superior electrical conductivity, corrosion resistance, and durability. By understanding the different types of gold-plated connectors, their manufacturing processes, and the factors affecting their performance, designers and engineers can select the most appropriate connectors for their specific needs.

As technology continues to advance, the demand for reliable and high-quality electrical connections will only increase. Gold-plated connectors will continue to play a crucial role in enabling the development of new technologies and ensuring the optimal performance of electronic devices and systems across various industries.

No responses yet