Introduction to PCB Surface Finish

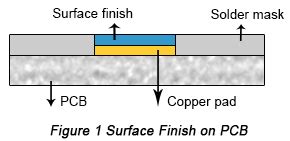

When designing and manufacturing a printed circuit board (PCB), one crucial aspect to consider is the surface finish. The PCB surface finish not only affects the aesthetic appearance of the board but also plays a significant role in its functionality, reliability, and longevity. Choosing the right surface finish for your PCB depends on various factors, such as the application, environmental conditions, soldering requirements, and cost constraints.

In this article, we will explore the different types of PCB surface finishes, their characteristics, advantages, and disadvantages. We will also discuss the factors to consider when selecting the appropriate surface finish for your specific project. By the end of this article, you will have a better understanding of how to choose the best surface finish for your PCB, ensuring optimal performance and reliability.

Types of PCB Surface Finishes

There are several types of PCB surface finishes available, each with its unique properties and benefits. Some of the most common surface finishes include:

1. Hot Air Solder Leveling (HASL)

HASL is one of the most widely used PCB surface finishes. In this process, the PCB is dipped into a molten solder bath, and then hot air is used to level the solder on the surface. This results in a uniform coating of solder on the exposed copper pads and through-holes.

Advantages:

– Cost-effective

– Excellent solderability

– Good shelf life

– Compatible with a wide range of soldering processes

Disadvantages:

– Uneven surface due to solder dipping process

– Potential for solder bridges and shorts

– Not suitable for fine-pitch components

– Contains lead (Pb), which may not be RoHS compliant

2. Immersion Silver (IAg)

Immersion silver is a chemical process that deposits a thin layer of silver onto the exposed copper surfaces of the PCB. This process provides excellent solderability and conductivity.

Advantages:

– Flat and uniform surface finish

– Excellent solderability

– Good electrical conductivity

– RoHS compliant

– Suitable for fine-pitch components

Disadvantages:

– Relatively short shelf life due to silver tarnishing

– Higher cost compared to HASL

– Potential for silver migration, causing short circuits

– Not suitable for high-temperature applications

3. Electroless Nickel Immersion Gold (ENIG)

ENIG is a two-step process that first deposits a layer of nickel onto the copper surface, followed by a thin layer of gold. The nickel layer provides a barrier against copper migration, while the gold layer offers excellent solderability and protection against oxidation.

Advantages:

– Flat and uniform surface finish

– Excellent solderability

– Good shelf life

– Suitable for fine-pitch components

– RoHS compliant

– Provides a barrier against copper migration

Disadvantages:

– Higher cost compared to HASL and IAg

– Potential for black pad syndrome (brittle nickel-phosphorus layer)

– Gold can dissolve into molten solder during assembly

4. Organic Solderability Preservative (OSP)

OSP is a chemical process that applies a thin, organic coating onto the copper surfaces of the PCB. This coating acts as a protective layer, preventing oxidation and preserving solderability.

Advantages:

– Cost-effective

– Flat and uniform surface finish

– Excellent solderability

– RoHS compliant

– Suitable for fine-pitch components

Disadvantages:

– Limited shelf life (typically 6-12 months)

– Requires careful handling and storage to maintain solderability

– Not suitable for multiple reflow cycles or rework

– Potential for contamination during the coating process

Factors to Consider When Choosing a PCB Surface Finish

When selecting the right surface finish for your PCB, there are several factors to consider:

1. Application and Environment

The intended application and the environment in which the PCB will be used play a crucial role in determining the appropriate surface finish. For example, if your PCB will be exposed to harsh environmental conditions, such as high humidity or corrosive atmospheres, you may want to choose a surface finish with better protection, such as ENIG.

2. Soldering Process and Component Compatibility

Different surface finishes have varying levels of solderability and compatibility with different soldering processes and component types. For instance, if your PCB requires fine-pitch components or multiple reflow cycles, you may want to opt for a surface finish like ENIG or IAg, which offer excellent solderability and are suitable for fine-pitch components.

3. Shelf Life and Storage Requirements

The shelf life and storage requirements of the surface finish should also be taken into account. Some surface finishes, like OSP, have a limited shelf life and require careful handling and storage to maintain their solderability. If your PCB needs to be stored for an extended period before assembly, you may want to choose a surface finish with a longer shelf life, such as ENIG.

4. Cost Considerations

The cost of the surface finish is another important factor to consider, especially for large-scale production or cost-sensitive projects. HASL is generally the most cost-effective option, while ENIG tends to be the most expensive. It’s essential to balance the cost with the required performance and reliability of your PCB.

Comparison of PCB Surface Finishes

To help you make an informed decision, here’s a comparison table of the four main PCB surface finishes discussed in this article:

| Surface Finish | Solderability | Shelf Life | Fine-Pitch Compatibility | Cost |

|---|---|---|---|---|

| HASL | Excellent | Good | Not suitable | Low |

| IAg | Excellent | Short | Suitable | Medium |

| ENIG | Excellent | Good | Suitable | High |

| OSP | Excellent | Limited | Suitable | Low |

FAQ

1. What is the most common PCB surface finish?

The most common PCB surface finish is Hot Air Solder Leveling (HASL). It is widely used due to its cost-effectiveness, excellent solderability, and compatibility with a wide range of soldering processes.

2. Which PCB surface finish is the most expensive?

Electroless Nickel Immersion Gold (ENIG) is generally the most expensive PCB surface finish. The two-step process of depositing nickel and gold layers contributes to its higher cost compared to other surface finishes.

3. Which PCB surface finish is RoHS compliant?

Immersion Silver (IAg), Electroless Nickel Immersion Gold (ENIG), and Organic Solderability Preservative (OSP) are all RoHS compliant surface finishes. HASL, on the other hand, may not be RoHS compliant if it contains lead (Pb).

4. What is the shelf life of Organic Solderability Preservative (OSP)?

The shelf life of OSP is typically 6-12 months. It is relatively limited compared to other surface finishes and requires careful handling and storage to maintain its solderability.

5. Which PCB surface finish is suitable for fine-pitch components?

Immersion Silver (IAg), Electroless Nickel Immersion Gold (ENIG), and Organic Solderability Preservative (OSP) are all suitable for fine-pitch components. These surface finishes provide a flat and uniform surface that allows for accurate placement and soldering of fine-pitch components.

Conclusion

Selecting the right surface finish for your PCB is a critical decision that impacts the performance, reliability, and cost of your electronic device. By understanding the different types of PCB surface finishes, their advantages, and disadvantages, and considering factors such as the application, soldering process, shelf life, and cost, you can make an informed choice that best suits your project requirements.

Remember, there is no one-size-fits-all solution when it comes to PCB surface finishes. Each project has its unique demands, and it’s essential to evaluate your specific needs before making a decision. If you’re unsure about which surface finish to choose, consult with your PCB manufacturer or an experienced electronics engineer to get expert advice tailored to your project.

By selecting the right PCB surface finish, you can ensure that your electronic device performs optimally, maintains its reliability over time, and meets the required industry standards and regulations. With the knowledge gained from this article, you are now better equipped to make the best choice for your PCB surface finish, contributing to the success of your electronic projects.

No responses yet