Introduction to PCB Surface Finish

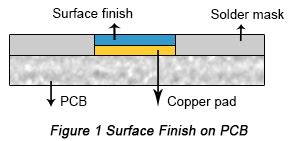

When designing and manufacturing printed circuit boards (PCBs), selecting the appropriate surface finish is crucial for ensuring optimal performance, reliability, and longevity. The surface finish not only protects the copper traces from oxidation and corrosion but also enhances the solderability and electrical conductivity of the board. With a variety of surface finish options available, it is essential to understand their characteristics, advantages, and limitations to make an informed decision based on your specific application requirements.

In this comprehensive article, we will explore the various PCB surface finish options, their properties, and the factors to consider when choosing the right finish for your project. We will also delve into the benefits and drawbacks of each surface finish, as well as their suitability for different manufacturing processes and environmental conditions.

The Importance of Choosing the Right PCB Surface Finish

Protection against Oxidation and Corrosion

One of the primary functions of a PCB surface finish is to protect the exposed copper traces from oxidation and corrosion. Copper, being a highly reactive metal, readily oxidizes when exposed to air and moisture, forming a layer of copper oxide on its surface. This oxidation process can lead to reduced electrical conductivity, poor solderability, and decreased reliability of the PCB. By applying a suitable surface finish, the copper traces are shielded from the environment, preventing oxidation and ensuring the long-term integrity of the board.

Enhancing Solderability

Another critical aspect of PCB surface finish is its impact on solderability. Solderability refers to the ease and effectiveness with which solder can wet and bond to the surface of the PCB. A good surface finish should promote excellent solder wetting, allowing for the formation of strong and reliable solder joints between components and the board. Poor solderability can result in weak or inconsistent solder connections, leading to potential failures and reduced reliability of the assembled PCB.

Electrical Conductivity

The surface finish also plays a role in the electrical conductivity of the PCB. While the copper traces themselves are highly conductive, the surface finish material can impact the overall conductivity of the board. Some surface finishes, such as immersion silver and electroless nickel/immersion gold (ENIG), offer excellent electrical conductivity, making them suitable for high-frequency and high-speed applications. On the other hand, surface finishes with lower conductivity, such as organic solderability preservatives (OSP), may be more appropriate for general-purpose applications.

Compatibility with Manufacturing Processes

When selecting a PCB surface finish, it is crucial to consider its compatibility with the manufacturing processes involved in assembling the board. Different surface finishes have varying levels of compatibility with soldering techniques, such as wave soldering, reflow soldering, and hand soldering. Some finishes may require specific processing conditions or have limitations in terms of the maximum soldering temperature they can withstand. Choosing a surface finish that is compatible with your manufacturing processes ensures smooth and reliable assembly of components onto the PCB.

Environmental Considerations

Environmental factors also play a significant role in the selection of PCB surface finish. Depending on the intended operating environment of the PCB, certain surface finishes may be more suitable than others. For example, in harsh environments with high humidity or exposure to corrosive agents, a surface finish with excellent corrosion resistance, such as ENIG or immersion tin, may be preferred. On the other hand, in applications with strict environmental regulations, such as RoHS (Restriction of Hazardous Substances) compliance, lead-free surface finishes like immersion silver or OSP may be required.

Common PCB Surface Finish Options

Hot Air Solder Leveling (HASL)

Hot Air Solder Leveling (HASL) is one of the most widely used PCB surface finishes. The process involves dipping the PCB into a molten solder bath, typically consisting of a tin-lead alloy, and then using hot air to level the solder on the surface. HASL provides excellent solderability and is compatible with most soldering processes. However, it can result in an uneven surface due to the formation of solder bumps, which may pose challenges for fine-pitch components. Additionally, the use of lead in the solder alloy raises environmental concerns, leading to the development of lead-free HASL alternatives.

Advantages:

– Excellent solderability

– Good shelf life

– Cost-effective

– Widely available and well-established process

Disadvantages:

– Uneven surface due to solder bumps

– Limitations for fine-pitch components

– Environmental concerns with lead-based solder alloys

Electroless Nickel Immersion Gold (ENIG)

Electroless Nickel Immersion Gold (ENIG) is a popular choice for high-reliability and high-performance applications. The process involves depositing a layer of nickel onto the copper traces through an autocatalytic chemical reaction, followed by a thin layer of gold deposited through immersion. ENIG offers excellent solderability, flatness, and corrosion resistance. The gold layer provides a protective barrier against oxidation, while the nickel layer acts as a diffusion barrier, preventing the formation of brittle intermetallic compounds. However, ENIG is relatively expensive compared to other surface finishes and may be prone to “black pad” syndrome, where the nickel layer separates from the copper substrate.

Advantages:

– Excellent solderability and wettability

– Flat and uniform surface

– Good corrosion resistance

– Suitable for fine-pitch components

– Excellent shelf life

Disadvantages:

– Higher cost compared to other surface finishes

– Potential for “black pad” syndrome

– Sensitive to process control and contamination

Immersion Silver

Immersion silver is a lead-free surface finish that involves depositing a thin layer of silver onto the copper traces through a chemical displacement reaction. It offers excellent solderability, electrical conductivity, and a flat surface finish. Immersion silver is also compatible with aluminum wire bonding, making it suitable for certain packaging applications. However, it has a limited shelf life due to the tendency of silver to tarnish over time, which can affect solderability. Additionally, immersion silver is sensitive to sulfur-containing environments and may require special handling and storage conditions.

Advantages:

– Excellent solderability

– Good electrical conductivity

– Flat and uniform surface

– Suitable for aluminum wire bonding

– RoHS compliant and lead-free

Disadvantages:

– Limited shelf life due to silver tarnishing

– Sensitivity to sulfur-containing environments

– May require special handling and storage conditions

Organic Solderability Preservative (OSP)

Organic Solderability Preservative (OSP) is a lead-free and cost-effective surface finish option. It involves applying a thin, organic coating onto the copper traces to protect them from oxidation. OSP is compatible with most soldering processes and provides good solderability. However, it has a limited shelf life and may require careful handling to prevent contamination of the coating. OSP is also sensitive to high temperatures and may not be suitable for multiple reflow cycles or high-temperature applications.

Advantages:

– Cost-effective

– Good solderability

– Lead-free and RoHS compliant

– Suitable for most soldering processes

Disadvantages:

– Limited shelf life

– Sensitive to contamination and handling

– May not be suitable for high-temperature applications or multiple reflow cycles

Immersion Tin

Immersion tin is another lead-free surface finish that involves depositing a layer of pure tin onto the copper traces through a chemical displacement reaction. It offers good solderability, excellent corrosion resistance, and is compatible with most soldering processes. Immersion tin is also relatively cost-effective compared to other surface finishes. However, it is prone to the formation of tin whiskers, which are thin, conductive filaments that can grow from the tin surface and cause short circuits. Proper process control and the use of tin alloys with added elements can help mitigate the risk of tin whisker formation.

Advantages:

– Good solderability

– Excellent corrosion resistance

– Cost-effective

– Compatible with most soldering processes

– RoHS compliant and lead-free

Disadvantages:

– Prone to tin whisker formation

– May require additional process control measures to mitigate tin whisker risk

Factors to Consider When Selecting PCB Surface Finish

Application Requirements

The intended application of the PCB is a critical factor in selecting the appropriate surface finish. Different applications may have specific requirements in terms of solderability, electrical performance, environmental resistance, and reliability. For example, high-frequency and high-speed applications may require surface finishes with excellent electrical conductivity, such as immersion silver or ENIG. On the other hand, applications exposed to harsh environments may prioritize corrosion resistance and opt for finishes like ENIG or immersion tin.

Manufacturing Process Compatibility

The compatibility of the surface finish with the manufacturing processes used in PCB Assembly is another essential consideration. Different soldering techniques, such as wave soldering, reflow soldering, and hand soldering, may have specific requirements or limitations when it comes to surface finishes. It is crucial to choose a surface finish that is compatible with the soldering processes employed in your manufacturing setup to ensure reliable and consistent solder joint formation.

Cost and Budget Constraints

Cost is often a significant factor in the selection of PCB surface finish. Different surface finishes have varying costs associated with them, depending on the materials used, processing steps involved, and the overall complexity of the finish. It is important to consider the cost implications of each surface finish option and align them with your project budget. While some high-performance finishes like ENIG may have a higher cost, they may be justified for critical applications that demand superior reliability and performance.

Environmental Regulations and Sustainability

Environmental regulations and sustainability considerations are becoming increasingly important in the electronics industry. When selecting a PCB surface finish, it is necessary to consider compliance with environmental directives such as RoHS, which restricts the use of certain hazardous substances, including lead. Lead-free surface finishes, such as immersion silver, OSP, and immersion tin, are preferred options for meeting RoHS requirements. Additionally, the environmental impact of the surface finish process itself, including waste generation and energy consumption, should be taken into account.

Shelf Life and Storage Conditions

The shelf life and storage conditions of the PCB surface finish are also important factors to consider. Some surface finishes, such as OSP and immersion silver, have limited shelf life due to the tendency of the protective coating to degrade over time. This can impact the solderability and reliability of the PCB if not used within the specified shelf life. Other finishes, like ENIG and immersion tin, have longer shelf life and are less sensitive to storage conditions. It is essential to consider the expected storage duration and conditions of your PCBs and choose a surface finish that can maintain its integrity throughout the required period.

Comparison of PCB Surface Finishes

| Surface Finish | Solderability | Flatness | Corrosion Resistance | Shelf Life | Cost |

|---|---|---|---|---|---|

| HASL | Excellent | Poor | Good | Long | Low |

| ENIG | Excellent | Excellent | Excellent | Long | High |

| Immersion Silver | Excellent | Excellent | Good | Limited | Moderate |

| OSP | Good | Excellent | Poor | Limited | Low |

| Immersion Tin | Good | Excellent | Excellent | Long | Moderate |

Frequently Asked Questions (FAQ)

-

Q: What is the most cost-effective PCB surface finish option?

A: Organic Solderability Preservative (OSP) and Hot Air Solder Leveling (HASL) are generally the most cost-effective PCB surface finish options. However, it is important to consider other factors such as application requirements, manufacturing compatibility, and environmental regulations when making the final decision. -

Q: Which surface finish is best suited for high-frequency applications?

A: For high-frequency applications, surface finishes with excellent electrical conductivity, such as immersion silver and Electroless Nickel Immersion Gold (ENIG), are preferred. These finishes provide a smooth and uniform surface, minimizing signal loss and ensuring optimal high-frequency performance. -

Q: Are all PCB surface finishes RoHS compliant?

A: No, not all PCB surface finishes are RoHS compliant. Surface finishes that contain lead, such as traditional Hot Air Solder Leveling (HASL) with lead-based solder alloys, do not meet RoHS requirements. Lead-free alternatives, such as immersion silver, OSP, immersion tin, and lead-free HASL, are RoHS compliant options. -

Q: What is the shelf life of different PCB surface finishes?

A: The shelf life of PCB surface finishes varies depending on the specific finish. ENIG and immersion tin have a relatively long shelf life, typically exceeding 12 months. On the other hand, OSP and immersion silver have limited shelf life, usually around 6 months, due to the degradation of the protective coating over time. HASL has a long shelf life, but the solder surface may oxidize over extended periods. -

Q: Can the choice of PCB surface finish affect the reliability of the assembled board?

A: Yes, the choice of PCB surface finish can impact the reliability of the assembled board. Surface finishes play a crucial role in protecting the copper traces from oxidation and ensuring good solderability. Finishes with excellent corrosion resistance, such as ENIG and immersion tin, can enhance the long-term reliability of the PCB. Additionally, the compatibility of the surface finish with the soldering process and the formation of reliable solder joints are critical factors in the overall reliability of the assembled board.

Conclusion

Selecting the right surface finish for your PCB is a critical decision that requires careful consideration of various factors, including application requirements, manufacturing compatibility, cost, environmental regulations, and shelf life. Each surface finish option has its own advantages and limitations, and the choice ultimately depends on the specific needs of your project.

By understanding the characteristics and properties of different surface finishes, such as HASL, ENIG, immersion silver, OSP, and immersion tin, you can make an informed decision that balances performance, reliability, and cost-effectiveness. It is also essential to work closely with your PCB manufacturer and assembly partner to ensure that the selected surface finish is compatible with their processes and meets the required quality standards.

Investing time and effort in choosing the appropriate PCB surface finish can significantly contribute to the success and longevity of your electronic products. By considering the factors discussed in this article and leveraging the expertise of industry professionals, you can optimize the performance and reliability of your PCBs while meeting the demands of your specific application.

Word count: 2634 words

No responses yet