What are PCB Manufacturing Tolerances?

PCB manufacturing tolerances refer to the acceptable range of variation in the dimensions and properties of a printed circuit board (PCB) that can occur during the manufacturing process. These tolerances are essential to ensure that the PCB functions as intended and meets the required specifications.

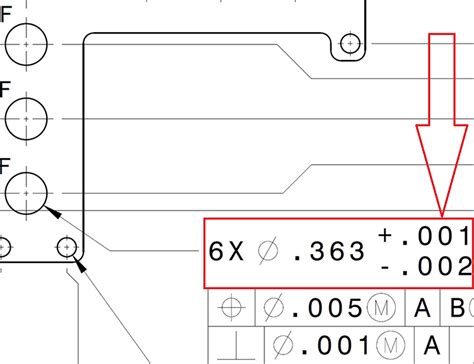

Manufacturing tolerances are typically expressed as a plus or minus (±) value, indicating the maximum allowable deviation from the nominal or desired value. For example, if a PCB track has a nominal width of 0.2 mm with a tolerance of ±0.05 mm, the actual track width can range from 0.15 mm to 0.25 mm and still be considered acceptable.

Why are PCB Manufacturing Tolerances Important?

PCB manufacturing tolerances play a crucial role in ensuring the reliability, performance, and functionality of the final product. Here are some key reasons why these tolerances are important:

-

Functionality: PCB Tolerances ensure that the board functions as intended. If the tolerances are not met, it can lead to issues such as short circuits, open circuits, or signal integrity problems, which can affect the overall performance of the device.

-

Compatibility: Adherence to manufacturing tolerances ensures that the PCB is compatible with other components and can be easily assembled. If the tolerances are not met, it may result in difficulties during the assembly process or even component failure.

-

Reliability: Maintaining the specified tolerances contributes to the long-term reliability of the PCB. Deviations from the tolerances can lead to premature failure or reduced lifespan of the board.

-

Cost-effectiveness: Adhering to manufacturing tolerances helps minimize production costs by reducing the number of rejected or reworked boards. It also ensures that the PCB can be manufactured consistently and efficiently.

Track Width Tolerances

Track width, also known as trace width, refers to the width of the copper tracks on a PCB. The track width is determined by the current carrying capacity required for the specific trace and the manufacturing capabilities of the PCB fabricator.

Factors Affecting Track Width Tolerances

Several factors can influence the track width tolerances on a PCB:

-

Manufacturing process: The PCB manufacturing process, such as etching or plating, can introduce variations in the track width. Different processes have different tolerances and limitations.

-

Copper thickness: The thickness of the copper layer on the PCB can affect the track width tolerances. Thicker copper layers generally have larger tolerances compared to thinner layers.

-

PCB material: The type of PCB material, such as FR-4 or high-frequency laminates, can impact the track width tolerances. Some materials have better dimensional stability and can achieve tighter tolerances.

-

Feature size: The overall feature size of the PCB, including the track width and spacing, can influence the achievable tolerances. Smaller features typically have tighter tolerances.

Typical Track Width Tolerances

The track width tolerances can vary depending on the PCB manufacturer and the specific manufacturing process used. However, here are some typical track width tolerances for different track sizes:

| Nominal Track Width | Tolerance |

|---|---|

| 0.1 mm | ±0.03 mm |

| 0.2 mm | ±0.05 mm |

| 0.3 mm | ±0.08 mm |

| 0.5 mm | ±0.10 mm |

| 1.0 mm | ±0.15 mm |

It’s important to consult with the PCB manufacturer to determine their specific track width tolerances and design guidelines to ensure the best results.

Isolation Gap Tolerances

Isolation gaps, also known as clearances, refer to the minimum distance between two adjacent copper features on a PCB, such as tracks, pads, or planes. These gaps provide electrical isolation and prevent short circuits between the copper elements.

Factors Affecting Isolation Gap Tolerances

Several factors can influence the isolation gap tolerances on a PCB:

-

Manufacturing process: The PCB manufacturing process, particularly the etching and plating steps, can introduce variations in the isolation gaps. Different processes have different tolerances and limitations.

-

PCB material: The type of PCB material can impact the isolation gap tolerances. Some materials have better dimensional stability and can achieve tighter tolerances.

-

Voltage requirements: The voltage requirements of the PCB design can dictate the minimum isolation gap needed to prevent electrical breakdown or arcing.

-

Feature size: The overall feature size of the PCB, including the track width and spacing, can influence the achievable isolation gap tolerances. Smaller features typically have tighter tolerances.

Typical Isolation Gap Tolerances

The isolation gap tolerances can vary depending on the PCB manufacturer and the specific manufacturing process used. However, here are some typical isolation gap tolerances for different voltage levels:

| Voltage Level | Minimum Isolation Gap |

|---|---|

| < 50 V | 0.1 mm |

| 50 V – 100 V | 0.2 mm |

| 100 V – 150 V | 0.3 mm |

| 150 V – 250 V | 0.6 mm |

| > 250 V | 1.0 mm |

These are general guidelines, and it’s essential to consult with the PCB manufacturer for their specific isolation gap tolerances and design recommendations based on the project requirements.

Designing with Manufacturing Tolerances in Mind

When designing a PCB, it’s crucial to consider manufacturing tolerances to ensure the board can be successfully fabricated and function as intended. Here are some tips for designing with tolerances in mind:

-

Understand the manufacturer’s capabilities: Consult with the PCB manufacturer to understand their specific manufacturing tolerances and design guidelines. This information will help you design a PCB that can be reliably manufactured.

-

Use appropriate design rules: Establish design rules in your PCB design software that incorporate the manufacturer’s tolerances. This includes setting the minimum track width, isolation gaps, and other relevant parameters.

-

Provide clear documentation: Clearly communicate the desired tolerances and any critical dimensions in the PCB design documentation. This helps the manufacturer understand your requirements and ensures that the PCB is fabricated to your specifications.

-

Consider the assembly process: When designing the PCB, also consider the tolerances and requirements of the assembly process, such as component placement and soldering. Ensure that the PCB design is compatible with the assembly tolerances to avoid issues during manufacturing.

-

Allow for additional margin: Where possible, design with additional margin or buffer to account for manufacturing tolerances. This can help ensure that the PCB functions correctly even if there are slight variations in the dimensions.

-

Perform design reviews: Conduct thorough design reviews to catch any potential issues related to manufacturing tolerances. This can include reviewing the PCB layout, performing design rule checks (DRC), and consulting with the manufacturer for feedback.

FAQ

1. What happens if the PCB manufacturing tolerances are not met?

If the PCB manufacturing tolerances are not met, it can lead to various issues, such as:

– Functionality problems: The PCB may not function as intended, resulting in performance issues or complete failure.

– Assembly difficulties: The PCB may not be compatible with the components or may be difficult to assemble, leading to delays and additional costs.

– Reliability concerns: Out-of-tolerance PCBs may have reduced reliability and a shorter lifespan compared to boards that meet the specified tolerances.

2. How can I ensure that my PCB design meets the manufacturing tolerances?

To ensure that your PCB design meets the manufacturing tolerances:

– Consult with the PCB manufacturer to understand their specific tolerances and design guidelines.

– Use appropriate design rules in your PCB design software that incorporate the manufacturer’s tolerances.

– Provide clear documentation of the desired tolerances and critical dimensions.

– Consider the tolerances of the assembly process when designing the PCB.

– Allow for additional margin or buffer in your design to account for manufacturing tolerances.

– Perform thorough design reviews and checks to identify any potential issues.

3. Can I request tighter tolerances for my PCB?

Yes, it is possible to request tighter tolerances for your PCB. However, keep in mind that tighter tolerances may increase the manufacturing cost and lead time. It’s important to discuss your specific requirements with the PCB manufacturer to determine the feasibility and cost implications of achieving tighter tolerances.

4. What is the impact of copper thickness on track width tolerances?

The thickness of the copper layer on the PCB can affect the track width tolerances. Generally, thicker copper layers have larger tolerances compared to thinner layers. This is because the etching process used to create the tracks becomes more challenging with increasing copper thickness. It’s essential to consider the copper thickness when specifying track width tolerances and consult with the PCB manufacturer for their recommendations.

5. How do I determine the appropriate isolation gap for my PCB design?

The appropriate isolation gap for your PCB design depends on several factors, including:

– Voltage requirements: Higher voltages typically require larger isolation gaps to prevent electrical breakdown or arcing.

– PCB material: Different PCB materials have varying dielectric properties and can influence the required isolation gap.

– Manufacturing process: The capabilities and tolerances of the PCB manufacturing process can impact the achievable isolation gaps.

To determine the appropriate isolation gap, consult with the PCB manufacturer and refer to industry standards and guidelines specific to your application and voltage requirements. The manufacturer can provide recommendations based on their experience and the specific manufacturing process they use.

Conclusion

Understanding and properly specifying manufacturing tolerances is crucial for ensuring the successful fabrication and functionality of a PCB. Track width and isolation gap tolerances are two key aspects that designers must consider when creating PCB layouts.

By taking into account factors such as the manufacturing process, PCB material, copper thickness, and voltage requirements, designers can establish appropriate tolerances and design rules to ensure the PCB can be reliably manufactured and performs as intended.

Effective communication with the PCB manufacturer, clear documentation of requirements, and thorough design reviews are essential for managing manufacturing tolerances throughout the PCB development process.

By designing with tolerances in mind and collaborating closely with the PCB manufacturer, designers can minimize issues, reduce costs, and improve the overall quality and reliability of their PCB designs.

No responses yet