How Pre-heaters Work

Pre-heaters work by transferring heat from a heating medium to the substance being processed. The heating medium can be steam, hot water, thermal oil, or exhaust gases, depending on the application and the required temperature range. The substance being heated flows through tubes or passages inside the pre-heater, while the heating medium flows around the outside of the tubes or through a separate chamber.

The heat transfer occurs through a combination of conduction, convection, and radiation, depending on the design of the pre-heater and the properties of the fluids involved. Some common types of pre-heaters include:

1. Shell and Tube Pre-heaters

Shell and tube pre-heaters consist of a bundle of tubes enclosed in a cylindrical shell. The substance being heated flows through the tubes, while the heating medium flows through the shell and around the outside of the tubes. Baffles are often used to direct the flow of the heating medium and improve heat transfer.

2. Plate Heat Exchangers

Plate heat exchangers consist of a stack of thin metal plates with gaskets or welds around the edges. The substance being heated and the heating medium flow through alternate channels between the plates, allowing heat transfer to occur through the metal. Plate heat exchangers are compact and efficient, and can handle high pressures and temperatures.

3. Spiral Heat Exchangers

Spiral heat exchangers consist of two spiral channels wound around a central core. The substance being heated and the heating medium flow through the separate channels in a counter-current direction, allowing for efficient heat transfer. Spiral heat exchangers are compact and can handle high viscosity fluids and solid particles.

Benefits of Using Pre-heaters

Using pre-heaters in industrial processes can provide several benefits, including:

-

Increased efficiency: By pre-heating the substance before further processing, the overall energy requirements of the process can be reduced, leading to increased efficiency and cost savings.

-

Improved product quality: Pre-heating can help to ensure consistent temperature control throughout the process, which can lead to improved product quality and reduced defects.

-

Enhanced safety: Pre-heating can reduce the risk of thermal shock or sudden temperature changes, which can cause damage to equipment or pose safety hazards to personnel.

-

Reduced environmental impact: By improving energy efficiency and reducing fuel consumption, pre-heaters can help to reduce greenhouse gas emissions and other environmental impacts associated with industrial processes.

Applications of Pre-heaters

Pre-heaters are used in a wide range of industrial applications, some of which are described below:

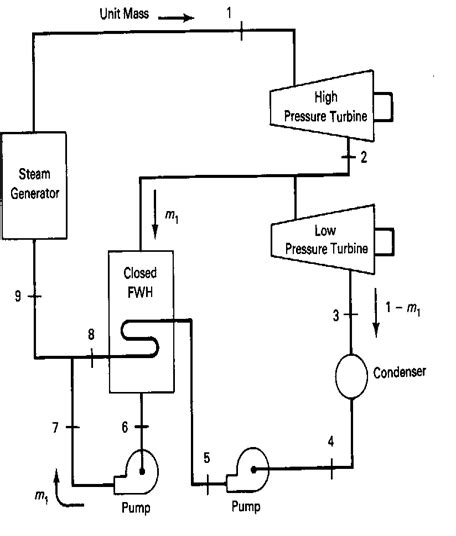

Power Generation

In power plants, pre-heaters are used to heat the feedwater before it enters the boiler. This helps to improve the efficiency of the steam cycle and reduce fuel consumption. Pre-heaters can also be used to heat the combustion air before it enters the furnace, which can improve combustion efficiency and reduce emissions.

Oil and Gas Processing

In oil and gas processing, pre-heaters are used to heat crude oil before it enters the distillation column. This helps to vaporize the lighter components of the oil and improve the separation efficiency. Pre-heaters can also be used to heat natural gas before it enters the processing plant, which can prevent hydrate formation and improve the efficiency of the gas treatment process.

Chemical Manufacturing

In chemical manufacturing, pre-heaters are used to heat reactants before they enter the reactor vessel. This can help to initiate the chemical reaction and improve the yield and selectivity of the process. Pre-heaters can also be used to heat solvents or other process fluids to the required temperature for extraction, distillation, or other separation processes.

Food Processing

In food processing, pre-heaters are used to heat raw materials before further processing, such as cooking, pasteurization, or sterilization. This can help to improve the quality and safety of the final product, as well as reduce processing times and energy consumption. Pre-heaters can also be used to heat water for washing or cleaning purposes in food processing facilities.

Design Considerations for Pre-heaters

When designing a pre-heater system for a specific application, several factors need to be considered, including:

-

Heat duty: The required heat transfer rate and temperature change will determine the size and type of pre-heater needed.

-

Fluid properties: The physical and chemical properties of the substance being heated and the heating medium, such as viscosity, density, thermal conductivity, and corrosivity, will influence the design of the pre-heater.

-

Operating conditions: The pressure, temperature, and flow rate of the fluids involved will affect the performance and safety of the pre-heater system.

-

Fouling: The potential for fouling or scaling on the heat transfer surfaces can reduce the efficiency of the pre-heater over time and may require periodic cleaning or maintenance.

-

Materials of construction: The materials used for the pre-heater components must be compatible with the fluids involved and able to withstand the operating conditions, including temperature, pressure, and corrosion.

Maintenance and Troubleshooting of Pre-heaters

To ensure the reliable and efficient operation of pre-heaters, regular maintenance and troubleshooting are essential. Some common issues that can arise with pre-heaters include:

-

Fouling: Over time, deposits can accumulate on the heat transfer surfaces, reducing the efficiency of the pre-heater. Regular cleaning and inspection can help to prevent or mitigate fouling.

-

Leaks: Leaks can occur in the tubes, gaskets, or other components of the pre-heater, leading to loss of fluid and reduced performance. Regular inspections and prompt repairs can help to prevent leaks.

-

Corrosion: Corrosion can occur due to the chemical properties of the fluids involved or the operating conditions, leading to damage to the pre-heater components. Proper material selection and corrosion monitoring can help to prevent or mitigate corrosion.

-

Thermal stress: Thermal stress can occur due to rapid temperature changes or uneven heating, leading to cracking or deformation of the pre-heater components. Proper design and operation can help to minimize thermal stress.

Regular maintenance activities for pre-heaters may include:

- Cleaning and inspection of heat transfer surfaces

- Replacement of gaskets, seals, or other wearing components

- Calibration and testing of instrumentation and controls

- Lubrication and adjustment of moving parts

- Non-destructive testing for cracks, corrosion, or other damage

FAQs

1. What is the difference between a pre-heater and a heat exchanger?

A pre-heater is a specific type of heat exchanger that is used to heat a substance before further processing. Heat exchangers, in general, are devices that transfer heat between two or more fluids, and can be used for heating, cooling, or other purposes.

2. Can pre-heaters be used for cooling applications?

While pre-heaters are primarily used for heating applications, they can also be used for cooling in some cases. For example, a pre-heater can be used to cool a hot process stream by transferring heat to a colder utility stream, such as cooling water or refrigerant.

3. What is the typical temperature range for pre-heaters?

The temperature range for pre-heaters can vary widely depending on the application and the fluids involved. Some pre-heaters may operate at temperatures below 100°C, while others may operate at temperatures above 1000°C. The specific temperature range will depend on the process requirements and the materials of construction.

4. How often should pre-heaters be inspected and cleaned?

The frequency of inspection and cleaning for pre-heaters will depend on the specific application and operating conditions. In general, pre-heaters should be inspected at least annually for signs of fouling, corrosion, or other damage. Cleaning may be required more frequently if the fluids involved are prone to fouling or if the pre-heater is operating under harsh conditions.

5. What are some common materials used for pre-heater construction?

The materials used for pre-heater construction will depend on the specific application and the fluids involved. Some common materials include:

- Carbon steel: For low-temperature and non-corrosive applications

- Stainless steel: For higher-temperature and mildly corrosive applications

- Alloy steels: For high-temperature and corrosive applications

- Nickel alloys: For very high-temperature and highly corrosive applications

- Titanium: For highly corrosive applications

- Graphite: For high-temperature and highly corrosive applications

The selection of materials will also depend on factors such as cost, availability, and ease of fabrication.

Conclusion

Pre-heaters are essential components in many industrial processes, providing a means to increase the temperature of a substance before further processing. By improving efficiency, product quality, safety, and environmental performance, pre-heaters can provide significant benefits to a wide range of industries, from power generation to food processing.

When designing and operating pre-heater systems, it is important to consider factors such as heat duty, fluid properties, operating conditions, fouling potential, and materials of construction. Regular maintenance and troubleshooting are also essential to ensure the reliable and efficient operation of pre-heaters over time.

As industrial processes continue to evolve and become more complex, the use of pre-heaters is likely to remain an important aspect of many applications. By understanding the function and benefits of pre-heaters, as well as the key design and maintenance considerations, engineers and operators can optimize the performance of their processes and achieve their operational goals.

No responses yet