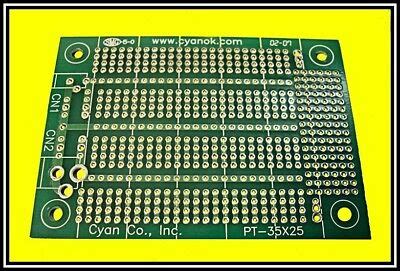

What is PCB Proto?

PCB Proto is a leading provider of printed circuit board (PCB) fabrication and assembly services. With state-of-the-art facilities and experienced engineers, PCB Proto offers high-quality PCB solutions for a wide range of industries, including aerospace, automotive, medical, and consumer electronics.

PCB Fabrication Services

PCB Proto provides comprehensive PCB fabrication services, from prototype to high-volume production. Their capabilities include:

| Service | Description |

|---|---|

| Multilayer PCBs | Up to 40 layers, with blind and buried vias |

| HDI PCBs | High-density interconnect boards with fine pitch and micro vias |

| Flex and Rigid-Flex PCBs | Flexible and combination flexible/rigid boards |

| Specialty Materials | Including high-frequency, high-temperature, and metal core substrates |

PCB Proto uses advanced manufacturing techniques, such as laser drilling, plasma etching, and direct imaging, to ensure precise and reliable PCB fabrication. They also offer a variety of surface finishes, solder masks, and silkscreen options to meet specific application requirements.

PCB Design Support

In addition to fabrication services, PCB Proto provides expert PCB design support to help customers optimize their designs for manufacturability and performance. Their team of experienced engineers can assist with:

- Schematic review and design rule checking (DRC)

- Component selection and placement

- Signal integrity analysis and simulation

- Thermal management and power distribution

- Design for manufacturing (DFM) and design for assembly (DFA)

By collaborating with PCB Proto’s design team, customers can reduce design iterations, improve product reliability, and accelerate time-to-market.

PCB Assembly Services

PCB Proto offers full Turnkey PCB assembly services, including surface mount technology (SMT) and through-hole assembly. Their capabilities include:

| Service | Description |

|---|---|

| SMT Assembly | Placement of components as small as 01005 and BGA packages |

| Through-Hole Assembly | Manual and automated insertion of through-hole components |

| Mixed Technology Assembly | Combination of SMT and through-hole components on the same board |

| Box Build Assembly | Complete product assembly, including PCBs, enclosures, and wiring |

PCB Proto’s assembly lines are equipped with the latest automated equipment, including high-speed pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. They also have experienced technicians for manual assembly and inspection.

Quality Control and Testing

To ensure the highest level of quality, PCB Proto implements strict quality control measures throughout the fabrication and assembly process. Their quality control procedures include:

- Incoming material inspection and vendor qualification

- In-process inspection and monitoring

- Final inspection and functional testing

- Automated optical inspection (AOI) and X-ray inspection

- Flying probe testing and in-circuit testing (ICT)

- Burn-in testing and environmental stress screening (ESS)

PCB Proto is ISO 9001 and ISO 14001 certified, and their facilities are compliant with IPC and ROHS standards. They also offer traceability and documentation services to meet customer and regulatory requirements.

Industries Served

PCB Proto serves a diverse range of industries with their PCB fabrication and assembly services. Some of the key industries they work with include:

Aerospace and Defense

PCB Proto provides high-reliability PCBs and assemblies for aerospace and defense applications, including avionics, communications, and surveillance systems. They are familiar with military and aerospace standards such as MIL-PRF-31032, MIL-PRF-55110, and IPC-6012 Class 3.

Automotive

For the automotive industry, PCB Proto offers PCB solutions for infotainment systems, engine control units, and advanced driver assistance systems (ADAS). They are experienced with automotive quality standards such as IATF 16949 and AEC-Q100.

Medical

PCB Proto serves the medical industry with PCBs and assemblies for diagnostic equipment, patient monitoring devices, and implantable devices. They are certified to ISO 13485 and are familiar with FDA regulations and standards.

Industrial and IoT

PCB Proto provides rugged and reliable PCB solutions for industrial applications, including factory automation, process control, and the Internet of Things (IoT). They offer PCBs with high-temperature materials, conformal coatings, and ruggedized assemblies.

Prototyping and Low-Volume Production

In addition to high-volume production, PCB Proto specializes in quick-turn prototyping and low-volume production. They understand the importance of fast prototyping for product development and testing, and offer the following services:

| Service | Description |

|---|---|

| Quick-Turn Prototypes | PCBs and assemblies in as fast as 24 hours |

| Low-Volume Production | Quantities from 1 to 1,000 pieces |

| Rapid Tooling | Laser-cut stencils and 3D-printed fixtures for fast setup |

| Expedited Shipping | Overnight and international shipping options |

PCB Proto’s prototyping services allow customers to quickly validate their designs, test functionality, and bring products to market faster.

PCB Proto’s Advantages

PCB Proto offers several key advantages that set them apart from other PCB fabrication and assembly providers:

-

Experience and Expertise: With over 20 years of experience in the PCB industry, PCB Proto has the knowledge and skills to handle complex PCB projects and provide expert guidance to customers.

-

Advanced Technology: PCB Proto invests in the latest manufacturing equipment and techniques to stay at the forefront of PCB technology. This allows them to offer cutting-edge PCB solutions and capabilities.

-

Quality and Reliability: PCB Proto is committed to delivering the highest quality PCBs and assemblies. Their strict quality control measures and certifications ensure consistent and reliable products.

-

Fast Turnaround: With quick-turn prototyping and low-volume production services, PCB Proto can help customers get their products to market faster without sacrificing quality.

-

Customer Service: PCB Proto prides itself on providing exceptional customer service. Their team of dedicated account managers and engineers work closely with customers to understand their needs and provide tailored solutions.

Frequently Asked Questions

-

What is the minimum order quantity for PCB fabrication?

PCB Proto has no minimum order quantity for PCB fabrication. They can produce PCBs in quantities from 1 to 1,000,000+. -

How long does it take to get a PCB Prototype?

PCB Proto offers quick-turn prototyping services, with PCBs and assemblies available in as fast as 24 hours. Standard lead times for prototypes are typically 3-5 days. -

What file formats does PCB Proto accept for PCB design?

PCB Proto accepts industry-standard file formats, including Gerber, ODB++, and IPC-2581. They also accept CAD files from popular PCB design software such as Altium, Cadence, and Mentor Graphics. -

Does PCB Proto offer design for manufacturing (DFM) services?

Yes, PCB Proto provides DFM services to help customers optimize their PCB designs for manufacturability and reliability. Their engineers can review designs, provide feedback, and suggest improvements. -

What certifications and standards does PCB Proto comply with?

PCB Proto is certified to ISO 9001 for quality management and ISO 14001 for environmental management. They are also compliant with IPC standards for PCB fabrication and assembly, as well as industry-specific standards such as IATF 16949 for automotive and ISO 13485 for medical devices.

Conclusion

PCB Proto is a trusted partner for PCB fabrication and assembly services, offering high-quality solutions for a wide range of industries. With their advanced technology, experienced team, and commitment to quality and customer service, PCB Proto can help bring your PCB projects to life. Whether you need quick-turn prototypes or high-volume production, PCB Proto has the capabilities and expertise to meet your needs. Contact them today to learn more about their PCB Services and how they can support your next project.

No responses yet