Key Features of Outer Annular Ring

The Outer Annular Ring possesses several key features that make it an essential component in many mechanical systems:

-

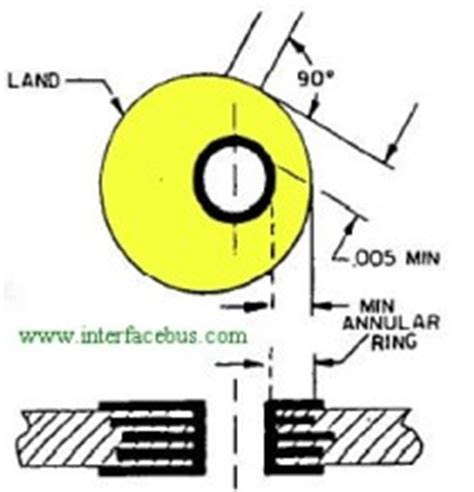

Shape: The OAR has a ring-like shape with a circular cross-section. This shape allows it to distribute loads evenly around its circumference, enhancing the overall structural integrity of the system.

-

Material: OARs are made from high-strength materials that can withstand significant loads and stresses. Common materials include:

- Steel alloys

- Aluminum alloys

- Titanium alloys

-

Composite materials (e.g., carbon fiber-reinforced polymers)

-

Size: The size of the OAR varies depending on the specific application. It can range from a few centimeters to several meters in diameter, with the thickness of the ring also varying accordingly.

-

Mounting: OARs are typically mounted using fasteners such as bolts or rivets. The mounting method ensures a secure connection between the OAR and the surrounding components, allowing for efficient load transfer.

Applications of Outer Annular Ring

Outer Annular Rings find applications in various industries and mechanical systems. Some of the most common applications include:

1. Aerospace Industry

In the aerospace industry, OARs are used in several key components:

-

Jet Engine Casings: OARs provide structural support and help maintain the shape of the engine casing, which is subjected to high temperatures and pressures during operation.

-

Aircraft Landing Gear: The OAR is a critical component in the landing gear assembly, helping to distribute the loads during takeoff and landing.

-

Helicopter Rotor Systems: OARs are used in the rotor hub assembly to support the rotor blades and transmit the rotational forces to the main rotor shaft.

2. Automotive Industry

OARs are used in various automotive applications:

-

Transmission Systems: OARs are used in planetary gear sets, where they act as the stationary ring gear, providing support and allowing the planetary gears to rotate around the sun gear.

-

Suspension Systems: In some suspension designs, OARs are used as part of the spring and damper assembly, helping to distribute loads and maintain the structural integrity of the system.

-

Wheel Hubs: OARs can be found in wheel hub assemblies, where they support the wheel bearings and help transfer the loads from the wheels to the suspension components.

3. Heavy Machinery

OARs are also used in heavy machinery, such as:

-

Earth-Moving Equipment: In excavators and other earth-moving machines, OARs are used in the slewing ring assembly, which allows the upper structure to rotate relative to the undercarriage.

-

Cranes: OARs are used in the slewing ring and hook block assemblies of cranes, helping to support the loads and facilitate the rotational motion.

Advantages of Using Outer Annular Rings

The use of Outer Annular Rings offers several advantages in mechanical systems:

-

Enhanced Structural Integrity: OARs provide additional support and help distribute loads evenly, reducing stress concentrations and improving the overall structural integrity of the system.

-

Increased Durability: The high-strength materials used in OARs, such as steel or titanium alloys, offer excellent durability and resistance to wear, fatigue, and environmental factors.

-

Improved Load Distribution: The ring-shaped design of the OAR allows for efficient load distribution around its circumference, minimizing localized stresses and ensuring a more balanced load transfer.

-

Versatility: OARs can be designed and manufactured to suit a wide range of applications, with variations in size, material, and mounting methods to meet specific requirements.

-

Ease of Maintenance: In many cases, OARs can be easily accessed and replaced if necessary, without requiring extensive disassembly of the entire system.

Manufacturing Process

The manufacturing process of Outer Annular Rings involves several key steps:

-

Material Selection: The appropriate material is selected based on the specific application, considering factors such as strength, stiffness, weight, and corrosion resistance.

-

Forging or Casting: The raw material is either forged or cast into the basic shape of the OAR. Forging involves shaping the material using compressive forces, while casting involves pouring molten metal into a mold.

-

Machining: The forged or cast OAR undergoes machining processes to achieve the desired dimensions and tolerances. This may include turning, milling, drilling, and grinding operations.

-

Heat Treatment: Depending on the material and the required properties, the OAR may undergo heat treatment processes such as quenching and tempering to improve its strength and durability.

-

Surface Finishing: The OAR may receive surface treatments such as plating, coating, or shot peening to enhance its corrosion resistance, wear resistance, or fatigue life.

-

Quality Control: Throughout the manufacturing process, strict quality control measures are implemented to ensure that the OAR meets the required specifications and performance criteria.

Design Considerations

When designing an Outer Annular Ring for a specific application, several key factors must be considered:

-

Load Requirements: The expected loads and stresses that the OAR will be subjected to must be carefully analyzed to ensure that the ring is designed with sufficient strength and stiffness.

-

Material Selection: The choice of material should take into account the specific requirements of the application, such as strength-to-weight ratio, corrosion resistance, and temperature stability.

-

Dimensional Constraints: The OAR must be designed to fit within the available space in the system, considering factors such as clearance, interference, and compatibility with surrounding components.

-

Mounting Method: The design of the OAR should incorporate appropriate provisions for mounting, such as bolt holes or welding surfaces, to ensure a secure and stable connection with the surrounding components.

-

Manufacturing Feasibility: The design of the OAR must be feasible from a manufacturing perspective, considering factors such as machinability, forgeability, and cost-effectiveness.

-

Fatigue Life: In applications where the OAR is subjected to cyclic loads, the design must account for fatigue life, ensuring that the ring can withstand the required number of load cycles without failure.

Maintenance and Inspection

To ensure the long-term reliability and performance of Outer Annular Rings, regular maintenance and inspection are essential:

-

Visual Inspection: Periodic visual inspections should be carried out to check for signs of damage, wear, or corrosion. Any identified issues should be addressed promptly to prevent further deterioration.

-

Non-Destructive Testing: Non-destructive testing techniques, such as ultrasonic testing or dye penetrant inspection, can be used to detect sub-surface cracks or defects that may not be visible during visual inspections.

-

Lubrication: In applications where the OAR interfaces with moving components, proper lubrication is crucial to reduce friction and wear. The lubrication schedule should be followed according to the manufacturer’s recommendations.

-

Fastener Checks: The fasteners used to mount the OAR should be regularly checked for tightness and integrity. Loose or damaged fasteners should be replaced to maintain the secure connection between the OAR and the surrounding components.

-

Replacement: If an OAR shows signs of excessive wear, damage, or fatigue, it should be replaced promptly to avoid potential failures or accidents.

Future Developments

As technology advances, there are several potential developments in the field of Outer Annular Rings:

-

Advanced Materials: Researchers are continually developing new materials with improved properties, such as higher strength-to-weight ratios, better fatigue resistance, and enhanced corrosion resistance. These advanced materials could lead to lighter, more durable OARs in the future.

-

Additive Manufacturing: Additive manufacturing techniques, such as 3D printing, are becoming increasingly popular in the manufacturing industry. These techniques could potentially be used to produce OARs with complex geometries or optimized designs that are difficult to achieve through traditional manufacturing methods.

-

Smart Monitoring: The integration of sensors and data acquisition systems into OARs could enable real-time monitoring of the component’s health and performance. This could help in predictive maintenance, allowing for timely interventions and reducing the risk of unexpected failures.

-

Composite Materials: The use of composite materials, such as carbon fiber-reinforced polymers, could offer significant weight savings and improved fatigue resistance compared to traditional metallic OARs. As composite manufacturing techniques continue to advance, their adoption in OAR applications may become more widespread.

-

Optimization Techniques: Advanced optimization techniques, such as topology optimization or generative design, could be used to create OAR designs that are lighter, stronger, and more efficient. These techniques leverage computational tools to generate optimized designs based on specific performance criteria and constraints.

Frequently Asked Questions (FAQ)

-

Q: What is the primary function of an Outer Annular Ring?

A: The primary function of an Outer Annular Ring is to provide structural support and help distribute loads evenly within a mechanical system. It is a critical component that ensures the stability and integrity of the system. -

Q: What materials are commonly used for manufacturing OARs?

A: Common materials used for manufacturing OARs include steel alloys, aluminum alloys, titanium alloys, and composite materials such as carbon fiber-reinforced polymers. The choice of material depends on the specific requirements of the application, such as strength, weight, and corrosion resistance. -

Q: How are OARs typically mounted in a mechanical system?

A: OARs are typically mounted using fasteners such as bolts or rivets. The mounting method ensures a secure connection between the OAR and the surrounding components, allowing for efficient load transfer. -

Q: What are some of the key applications of OARs in the aerospace industry?

A: In the aerospace industry, OARs are used in several key components, including jet engine casings, aircraft landing gear, and helicopter rotor systems. They provide structural support, maintain the shape of the components, and help distribute loads during operation. -

Q: How can the long-term reliability and performance of OARs be ensured?

A: To ensure the long-term reliability and performance of OARs, regular maintenance and inspection are essential. This includes visual inspections, non-destructive testing, lubrication, fastener checks, and timely replacement of worn or damaged components.

Conclusion

Outer Annular Rings play a vital role in ensuring the structural integrity, stability, and load distribution within various mechanical systems. Their ring-shaped design, high-strength materials, and versatile applications make them indispensable components in industries such as aerospace, automotive, and heavy machinery.

The design and manufacturing of OARs involve careful consideration of load requirements, material selection, dimensional constraints, and manufacturing feasibility. Regular maintenance and inspection are crucial to ensuring the long-term reliability and performance of these components.

As technology advances, there are exciting opportunities for further developments in the field of Outer Annular Rings, including the use of advanced materials, additive manufacturing techniques, smart monitoring systems, and optimization methods. These advancements could lead to lighter, stronger, and more efficient OARs in the future.

By understanding the key features, applications, and design considerations of Outer Annular Rings, engineers and manufacturers can continue to develop and improve these critical components, ultimately enhancing the performance and safety of the mechanical systems in which they are used.

| Component | Application | Key Features |

|---|---|---|

| Jet Engine Casings | Aerospace – Jet Engines | High-temperature resistance, structural support |

| Landing Gear | Aerospace – Aircraft | Load distribution during takeoff and landing |

| Rotor Hub Assembly | Aerospace – Helicopters | Support for rotor blades, load transmission |

| Transmission Systems | Automotive – Gearboxes | Support for planetary gears, stationary ring gear |

| Suspension Systems | Automotive – Shock Absorbers | Load distribution, structural integrity |

| Slewing Ring | Heavy Machinery – Excavators, Cranes | Allows rotation of upper structure, load support |

This table highlights some of the key applications of Outer Annular Rings in various industries, along with their specific functions and features in each application.

No responses yet