What is a CPL (Customer Parts List)?

A Customer Parts List, commonly abbreviated as CPL, is a comprehensive list of all the parts and components that go into a finished product from the customer’s perspective. The CPL focuses on the items that the customer interacts with or sees as part of the final product.

Key characteristics of a CPL include:

- Lists all customer-facing parts and assemblies

- Specifies part numbers, descriptions, and quantities

- May include both manufacturer-made and externally procured parts

- Helps define the product configuration from the customer’s view

- Used for spare parts identification, service, and maintenance

Here’s an example CPL table for a desktop computer:

| Level | Part Number | Description | Quantity |

|---|---|---|---|

| 0 | DT-1000 | Desktop Computer | 1 |

| 1 | DT-CASE | Computer Case | 1 |

| 1 | DT-MB | Motherboard | 1 |

| 1 | DT-CPU | CPU | 1 |

| 1 | DT-RAM | RAM | 2 |

| 1 | DT-HDD | Hard Drive | 1 |

| 1 | DT-PS | Power Supply | 1 |

| 1 | DT-KB | Keyboard | 1 |

| 1 | DT-MS | Mouse | 1 |

The CPL provides a clear, top-down view of what the customer will receive as the end product. It’s an essential document for spare parts identification, product servicing, and maintenance tasks.

What is a BOM (Bill of Materials)?

A Bill of Materials, or BOM, is an exhaustive list of all the raw materials, sub-assemblies, intermediate assemblies, sub-components, and components needed to construct, manufacture, or repair a product. The BOM goes much deeper than the CPL, drilling down to the lowest level of detail needed for production.

Important aspects of a BOM include:

- Hierarchical list of all components and materials

- Each item includes part number, description, quantity, and unit of measure

- May specify procurement type – made in-house or purchased from external supplier

- Acts as the recipe for building the complete product

- Essential for inventory management, procurement, and production planning

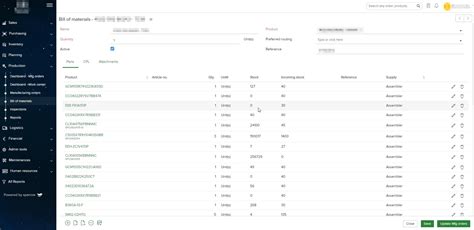

Let’s look at a simplified BOM table for the same desktop computer:

| Level | Part Number | Description | Quantity | UOM | Procurement |

|---|---|---|---|---|---|

| 0 | DT-1000 | Desktop Computer | 1 | EA | Made |

| 1 | DT-CASE | Computer Case | 1 | EA | Purchased |

| 1 | DT-ASSY | Main Assembly | 1 | EA | Made |

| 2 | DT-MB | Motherboard | 1 | EA | Purchased |

| 2 | DT-CPU | CPU | 1 | EA | Purchased |

| 2 | DT-CPU-FAN | CPU Fan | 1 | EA | Purchased |

| 2 | DT-RAM | RAM | 2 | EA | Purchased |

| 2 | DT-HDD | Hard Drive | 1 | EA | Purchased |

| 2 | DT-PS | Power Supply | 1 | EA | Purchased |

| 2 | DT-CABLES | Internal Cables | 1 | SET | Made |

| 3 | DT-CABLE-PP | Power Cable | 1 | EA | Purchased |

| 3 | DT-CABLE-HD | SATA Cable | 2 | EA | Purchased |

| 1 | DT-KB | Keyboard | 1 | EA | Purchased |

| 1 | DT-MS | Mouse | 1 | EA | Purchased |

The BOM is much more detailed than the CPL, including every item needed for production, down to the individual cables and fasteners. It specifies whether each item is made in-house or procured from an external supplier. The BOM is the foundation for inventory management, procurement, and production planning activities.

Key Differences Between CPL and BOM

While CPLs and BOMs are related, there are several crucial differences:

1. Level of Detail

The primary difference between a CPL and BOM is the level of detail each one provides.

-

CPL: The CPL is a high-level list focused on customer-facing parts and assemblies. It doesn’t go into the granular details of every single component.

-

BOM: The BOM, on the other hand, is a comprehensive, hierarchical list that includes every component and material needed to make the product, down to the lowest level of detail.

2. Purpose and Use

CPLs and BOMs serve different purposes within an organization.

-

CPL: The main use of the CPL is for spare parts identification, product servicing, and maintenance. It helps service teams quickly identify and order the correct replacement parts.

-

BOM: The BOM is used for production planning, inventory management, and procurement. It acts as the recipe for building the product and ensures that the right materials are available when needed.

3. Audience

The intended audience for CPLs and BOMs is different.

-

CPL: The CPL is primarily used by customer-facing teams, such as sales, customer service, and technical support. It helps these teams communicate effectively with customers about the product configuration.

-

BOM: The BOM is used internally by engineering, manufacturing, purchasing, and supply chain teams. It’s the central document that guides the production process.

4. Change Management

CPLs and BOMs are affected differently by product changes and revisions.

-

CPL: Changes to the CPL are typically driven by updates to the customer-facing aspects of the product, such as new features, options, or styling changes.

-

BOM: The BOM is impacted by any change to the product design, components, or manufacturing processes. Even minor changes, like a new supplier for a single part, require updating the BOM.

The Relationship Between CPLs and BOMs

While CPLs and BOMs serve different purposes, they are interconnected. The CPL can be thought of as a subset of the BOM, focusing on the customer-facing parts and assemblies.

In many cases, the CPL is derived from the BOM, with the non-customer-facing components and details removed. This ensures alignment between the two documents and helps maintain consistency in part numbering and descriptions.

Effective product data management requires keeping both the CPL and BOM accurate and up-to-date. Changes to either document need to be carefully coordinated to avoid discrepancies that could lead to production issues or customer confusion.

The Importance of CPLs and BOMs

Both CPLs and BOMs play critical roles in the product development and manufacturing process.

The CPL is essential for:

- Defining the product configuration from the customer’s perspective

- Identifying spare parts for field service and maintenance

- Communicating effectively with customers about the product

The BOM is the foundation for:

- Production planning and scheduling

- Inventory management and procurement

- Ensuring the right materials are available when needed

- Controlling product costs and managing suppliers

Without accurate and well-maintained CPLs and BOMs, companies risk a host of problems, including:

- Production delays and shortages

- Incorrect or inconsistent product configurations

- Difficulty identifying and ordering spare parts

- Increased product costs and waste

- Poor customer communication and satisfaction

Best Practices for Managing CPLs and BOMs

To ensure the accuracy and effectiveness of CPLs and BOMs, companies should follow these best practices:

-

Use a consistent numbering and naming convention for parts and assemblies across both documents.

-

Establish clear ownership and responsibility for maintaining each document.

-

Implement a robust change management process to ensure that updates to the CPL and BOM are coordinated and communicated to all stakeholders.

-

Utilize product lifecycle management (PLM) or product data management (PDM) software to centralize and control access to CPLs and BOMs.

-

Regularly audit and validate the accuracy of CPLs and BOMs against the actual product configuration and production processes.

By following these best practices, companies can ensure that their CPLs and BOMs remain accurate, up-to-date, and effective in supporting product development, manufacturing, and customer support activities.

Frequently Asked Questions (FAQ)

-

What is the main difference between a CPL and BOM?

The main difference is the level of detail. The CPL focuses on customer-facing parts and assemblies, while the BOM includes every component and material needed to make the product, down to the lowest level of detail. -

Can a product have multiple BOMs?

Yes, a product can have multiple BOMs, especially if there are different versions or configurations of the product. Each unique configuration would have its own BOM. -

How often should CPLs and BOMs be updated?

CPLs and BOMs should be updated whenever there is a change to the product design, components, or manufacturing processes. The frequency of updates depends on the complexity and lifecycle of the product. -

Who is responsible for creating and maintaining CPLs and BOMs?

The responsibility for CPLs and BOMs typically lies with the engineering and product management teams. However, multiple departments, including manufacturing, purchasing, and customer service, may contribute to and use these documents. -

What happens if there are discrepancies between the CPL and BOM?

Discrepancies between the CPL and BOM can lead to confusion, production issues, and customer dissatisfaction. It’s critical to identify and resolve any discrepancies as quickly as possible through a well-defined change management process.

Conclusion

CPLs and BOMs are two essential documents in the product development and manufacturing process. While they serve different purposes and audiences, both are critical for ensuring that products are built correctly, efficiently, and to the customer’s specifications.

Understanding the differences between CPLs and BOMs, as well as their interconnected nature, is essential for effective product data management. By following best practices for creating, maintaining, and updating these documents, companies can streamline their operations, reduce errors and waste, and ultimately deliver better products to their customers.

As product complexity continues to increase, the importance of accurate and well-managed CPLs and BOMs will only continue to grow. By mastering these critical concepts, product companies can position themselves for success in an increasingly competitive and dynamic marketplace.

No responses yet