Introduction to BGA Soldering

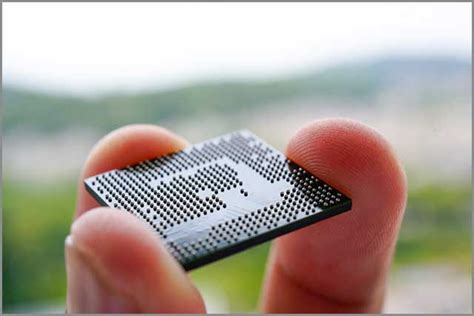

Ball Grid Array (BGA) is a surface-mount package with solder balls on the bottom side, used for integrated circuits. BGA soldering is the process of attaching a BGA component to a printed circuit board (PCB) using a reflow soldering process in surface mount technology (SMT) assembly.

BGA soldering can be challenging due to the high density of connections, the inability to visually inspect the solder joints, and the need for precise control of the reflow profile. However, with proper techniques and equipment, reliable BGA solder joints can be achieved consistently.

Importance of Proper BGA Soldering Techniques

Proper BGA soldering is critical for several reasons:

-

Reliability: Poor BGA solder joints can lead to intermittent or complete failure of the electronic device.

-

Rework costs: If BGA soldering is not done correctly the first time, costly and time-consuming rework may be required.

-

Quality: Properly soldered BGA joints ensure the overall quality and performance of the assembled PCB.

-

Yield: Good BGA soldering techniques help maximize manufacturing yield and minimize scrap.

9 Ways to Get BGA Soldering Right in SMT Assembly

1. PCB Design Considerations

Proper PCB design is the foundation for successful BGA soldering. Key considerations include:

- Adequate land pattern size and shape for the specific BGA package

- Proper via design and placement to prevent solder wicking

- Sufficient thermal relief connections to prevent heat damage

- Proper solder mask design to prevent bridging

Land Pattern Design

The land pattern is the arrangement of pads on the PCB that mate with the solder balls on the BGA component. The size and shape of the land pattern depend on the specific BGA package being used. IPC standards provide recommended land patterns for various BGA sizes and pitches.

| BGA Pitch (mm) | Ball Diameter (mm) | Pad Diameter (mm) | Pad Spacing (mm) |

|---|---|---|---|

| 1.00 | 0.60 | 0.60 | 1.00 |

| 0.80 | 0.50 | 0.50 | 0.80 |

| 0.75 | 0.45 | 0.45 | 0.75 |

| 0.65 | 0.40 | 0.40 | 0.65 |

| 0.50 | 0.30 | 0.30 | 0.50 |

(Source: IPC-7095)

2. Solder Paste Printing

Solder paste printing is the process of applying solder paste to the PCB pads using a stencil. The quality of the solder paste print is critical for BGA soldering success. Factors to control include:

- Stencil design: aperture size, shape, and position

- Solder paste properties: particle size, flux activity, viscosity

- Print parameters: squeegee pressure, speed, separation speed

- Stencil cleaning and maintenance

3. Component Placement

Accurate placement of the BGA component onto the PCB is essential for good soldering. Key considerations include:

- Placement accuracy: X, Y, and theta

- Placement force

- Vision system for alignment

- Nozzle design for secure picking

Modern pick-and-place machines can achieve placement accuracies of ±0.025 mm or better for BGA components.

4. Reflow Soldering Profile

The reflow soldering profile is the time-temperature curve that the PCB Assembly follows during the reflow process. A proper reflow profile is critical for achieving good BGA solder joints. Key stages of the reflow profile include:

-

Preheat: Gradual heating to activate the flux and remove solvents. Typical rate: 0.5-2°C/sec.

-

Thermal Soak: Holding at a temperature below melting to allow the entire assembly to reach a uniform temperature. Typical time: 60-120 sec.

-

Reflow: Quick heating above the solder melting temperature to allow the solder to melt, wet, and form intermetallic bonds. Typical peak: 20-40°C above melting point.

-

Cooling: Gradual cooling to solidify the solder joints without thermal shock. Typical rate: 2-6°C/sec.

The exact reflow profile depends on the specific solder paste being used and the thermal mass of the assembly. Solder paste manufacturers provide recommended profiles that can be used as a starting point.

5. Nitrogen Reflow

Reflowing BGA components in a nitrogen atmosphere can improve solder joint quality by reducing oxidation. Benefits of nitrogen reflow include:

- Shinier, smoother solder joints

- Reduced voids and solder balls

- Improved wetting and spreading of solder

- Extended life of reflow oven conveyor and heating elements

Typical nitrogen concentrations for BGA reflow are in the range of 500-1000 ppm oxygen. Higher-end reflow ovens have built-in nitrogen control systems.

6. Inspection and Testing

Post-reflow inspection and testing are important for verifying BGA solder joint quality. Common methods include:

-

X-ray inspection: Uses X-rays to image the solder joints hidden under the component. Can detect voids, bridging, and missing balls.

-

Automated optical inspection (AOI): Uses cameras and image analysis to inspect visible features of the solder joints. Can detect misalignment, insufficient solder, and lifted leads.

-

Electrical testing: Uses probes or test fixtures to verify electrical continuity and performance of the assembled PCB. Includes in-circuit test (ICT), flying probe test, and functional test.

Combining multiple inspection and test methods provides the best assurance of BGA solder joint quality.

7. Rework and Repair

Even with the best processes, some BGA soldering defects may occur. Reworking BGA components requires specialized equipment and techniques to avoid damaging the PCB or adjacent components. Common BGA Rework methods include:

-

Hot air pencil: Uses a focused hot air stream to locally reflow the solder joints. Requires skill to avoid overheating.

-

Infrared BGA station: Uses an IR heating head to reflow the entire BGA component. Provides more uniform heating than hot air.

-

Soldering iron: Used to manually touch up individual solder joints. Risk of bridging adjacent joints.

Successful BGA rework depends on proper equipment, training, and process control. Many contract manufacturers have dedicated BGA rework technicians and stations.

8. Process Control and Monitoring

Maintaining a stable and repeatable BGA soldering process requires ongoing monitoring and control. Key process parameters to track include:

- Solder paste print quality: deposit volume, height, area

- Reflow oven temperature profiles

- Nitrogen concentration levels

- Component placement accuracy

- Visual and X-ray inspection results

- Electrical test yields

Statistical process control (SPC) techniques, such as control charts and process capability analysis, can be used to detect trends and variations in the process. Regular maintenance and calibration of equipment are also important for process stability.

9. Training and Skill Development

BGA soldering requires a high level of skill and experience to perform consistently. Investing in training and skill development for SMT assembly operators and technicians is essential. Training topics may include:

- BGA package types and characteristics

- PCB design for BGA assembly

- Solder paste printing techniques

- BGA component placement

- Reflow profile optimization

- Nitrogen reflow operation

- X-ray and AOI Inspection

- BGA rework and repair

Many equipment vendors, solder paste suppliers, and industry associations offer training courses and certifications related to BGA soldering. Online resources, such as webinars and application notes, can also be valuable for learning best practices.

Frequently Asked Questions (FAQ)

1. What is the main challenge with BGA soldering compared to other SMT packages?

The main challenge with BGA soldering is the inability to visually inspect the solder joints, which are hidden under the component. This makes it more difficult to detect and rework soldering defects.

2. How does PCB design affect BGA soldering?

PCB Design Factors such as land pattern size and shape, via placement, and solder mask design can greatly affect the quality of BGA solder joints. Proper PCB design is essential for preventing issues like bridging, wicking, and insufficient solder.

3. What are the key parameters to control in the reflow soldering profile for BGA components?

The key parameters to control in the BGA reflow profile are the preheat rate, soak time and temperature, reflow peak temperature and time above melting, and cooling rate. The specific values depend on the solder paste and PCB characteristics.

4. How does nitrogen reflow improve BGA soldering?

Nitrogen reflow improves BGA soldering by reducing oxidation of the solder joints, resulting in shinier, smoother joints with fewer voids and solder balls. It also improves wetting and spreading of the solder.

5. What are some common methods for inspecting and testing BGA solder joints?

Common methods for inspecting and testing BGA solder joints include X-ray inspection to detect hidden defects, automated optical inspection (AOI) for visible defects, and electrical testing such as in-circuit test (ICT) and functional test to verify performance.

Conclusion

BGA soldering is a critical process in SMT assembly that requires careful design, process control, and skill to achieve consistently reliable results. By following best practices in PCB design, solder paste printing, component placement, reflow soldering, inspection, and rework, manufacturers can overcome the challenges of BGA soldering and produce high-quality assemblies.

As electronic products continue to miniaturize and increase in complexity, the importance of proper BGA soldering will only continue to grow. By investing in the right equipment, processes, and training, manufacturers can stay ahead of the curve and meet the evolving demands of the industry.

No responses yet