Introduction to White PCB

White PCBs, also known as solder mask white PCBs or white solder mask PCBs, are printed circuit boards that feature a white solder mask layer instead of the more common green color. The white solder mask provides a unique aesthetic appeal and offers several advantages over traditional green PCBs. In this comprehensive guide, we will delve into the world of white PCBs, exploring their characteristics, applications, manufacturing process, and more.

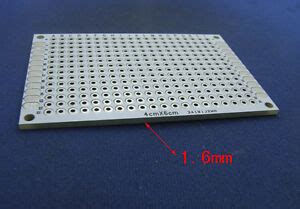

What is a White PCB?

A white PCB is a printed circuit board that utilizes a white solder mask layer. The solder mask is a thin, protective coating applied to the copper traces of the PCB to prevent short circuits and improve the board’s durability. While green is the most common color for solder masks, white has gained popularity in recent years due to its distinctive appearance and certain benefits it offers.

Characteristics of White PCBs

White PCBs possess several unique characteristics that set them apart from traditional green PCBs:

-

Aesthetics: The white solder mask provides a clean, modern, and visually appealing look to the PCB. It can enhance the overall appearance of electronic devices, making them more attractive to consumers.

-

Contrast: The white background offers excellent contrast against the copper traces and components, making it easier to inspect and troubleshoot the PCB during manufacturing and assembly processes.

-

Reflectivity: White solder mask is more reflective than green, which can be beneficial in certain applications where light reflection is desired, such as LED lighting systems.

-

Thermal Properties: White PCBs have better thermal properties compared to green PCBs. The white color helps reflect heat, which can improve the thermal management of the electronic components on the board.

Applications of White PCBs

White PCBs find applications in various industries and products. Some common applications include:

-

Consumer Electronics: White PCBs are often used in consumer electronic devices such as smartphones, tablets, laptops, and wearables to enhance their visual appeal and provide a premium look.

-

LED Lighting: The reflective nature of white PCBs makes them ideal for LED lighting applications. The white solder mask helps distribute the light more evenly and efficiently, resulting in better illumination.

-

Automotive Electronics: White PCBs are used in automotive electronics, particularly in dashboard displays and infotainment systems, where clarity and contrast are crucial.

-

Medical Devices: The clean and sterile appearance of white PCBs makes them suitable for medical devices and equipment, where hygiene and cleanliness are of utmost importance.

-

Industrial Control Systems: White PCBs are used in industrial control systems, such as process control panels and automation systems, where clear labeling and easy identification of components are essential.

Manufacturing Process of White PCBs

The manufacturing process of white PCBs is similar to that of traditional green PCBs, with a few additional considerations:

-

PCB Design: The PCB design is created using electronic design automation (EDA) software. The design includes the copper traces, component placement, and drill holes.

-

Copper Lamination: A thin layer of copper is laminated onto the insulating substrate material, typically FR-4, using heat and pressure.

-

Photoresist Application: A photoresist layer is applied to the copper-laminated substrate. The photoresist is a light-sensitive material that hardens when exposed to ultraviolet (UV) light.

-

Exposure and Development: The PCB is exposed to UV light through a photomask, which selectively hardens the photoresist layer based on the desired circuit pattern. The unexposed areas of the photoresist are then removed using a chemical developer solution.

-

Etching: The exposed copper areas are etched away using a chemical solution, leaving behind the desired copper traces.

-

Solder Mask Application: The white solder mask is applied to the PCB using screen printing or liquid photo imaging (LPI) techniques. The solder mask covers the copper traces, leaving only the exposed pads for component soldering.

-

Silkscreen Printing: The component labels, logos, and other markings are printed onto the white solder mask using silkscreen printing.

-

Surface Finish: A surface finish, such as immersion gold (ENIG) or immersion silver (IAg), is applied to the exposed pads to prevent oxidation and improve solderability.

-

Drilling: Holes are drilled through the PCB for through-hole components and vias.

-

Electrical Testing: The PCB undergoes electrical testing to ensure proper functionality and connectivity.

Advantages of White PCBs

White PCBs offer several advantages over traditional green PCBs:

-

Enhanced Visual Appeal: The white color provides a clean and modern look, making electronic devices more attractive to consumers.

-

Improved Contrast: The white background offers better contrast against the copper traces and components, facilitating inspection and troubleshooting processes.

-

Better Thermal Management: White PCBs have better thermal properties, helping to dissipate heat more effectively and improve the overall thermal management of the electronic components.

-

Increased Reflectivity: The reflective nature of white solder mask is beneficial in applications where light reflection is desired, such as LED lighting systems.

-

Versatility: White PCBs can be used in a wide range of applications, from consumer electronics to medical devices and industrial control systems.

Challenges and Considerations

While white PCBs offer numerous benefits, there are also some challenges and considerations to keep in mind:

-

Cost: White PCBs may be slightly more expensive than green PCBs due to the specialized solder mask material and additional processing steps involved.

-

Availability: Not all PCB manufacturers offer white solder mask as a standard option, so it may require finding a specialized supplier or requesting custom manufacturing.

-

Solder Mask Compatibility: Ensure that the white solder mask is compatible with the desired surface finish and the soldering process to be used.

-

Handling and Cleanliness: White PCBs may show dirt, smudges, and fingerprints more easily than green PCBs, requiring extra care in handling and cleaning during the manufacturing and assembly processes.

Choosing the Right White PCB Manufacturer

When selecting a white PCB manufacturer, consider the following factors:

-

Experience: Look for a manufacturer with experience in producing white PCBs and a proven track record of quality and reliability.

-

Capabilities: Ensure that the manufacturer has the necessary equipment and expertise to handle the specific requirements of your white PCB project, such as the desired surface finish and solder mask application method.

-

Quality Control: Inquire about the manufacturer’s quality control processes and certifications, such as ISO 9001 and IPC standards, to ensure consistent quality and adherence to industry standards.

-

Turnaround Time: Consider the manufacturer’s lead time and ability to meet your production schedule, especially for time-sensitive projects.

-

Customer Support: Choose a manufacturer that offers responsive and knowledgeable customer support to address any questions or concerns throughout the manufacturing process.

White PCB Design Considerations

When designing a white PCB, keep the following considerations in mind:

-

Solder Mask Thickness: Ensure that the white solder mask is applied with the appropriate thickness to provide adequate protection and insulation for the copper traces.

-

Silkscreen Legibility: Choose a silkscreen color that provides good contrast against the white background for clear and legible component labels and markings.

-

Component Placement: Consider the placement of components to maximize the aesthetic appeal of the white PCB and ensure proper functionality.

-

Thermal Management: Take into account the thermal properties of the white solder mask and design the PCB layout accordingly to optimize heat dissipation.

-

Manufacturing Constraints: Consult with the PCB manufacturer to understand any specific design guidelines or constraints related to white PCBs, such as minimum trace widths and clearances.

Frequently Asked Questions (FAQ)

1. Are white PCBs more expensive than green PCBs?

Yes, white PCBs may be slightly more expensive than green PCBs due to the specialized solder mask material and additional processing steps involved.

2. Can white PCBs be used for all types of electronic devices?

White PCBs can be used in a wide range of applications, from consumer electronics to medical devices and industrial control systems. However, the suitability of a white PCB depends on the specific requirements and constraints of each project.

3. How does the thermal performance of white PCBs compare to green PCBs?

White PCBs have better thermal properties compared to green PCBs. The white color helps reflect heat, which can improve the thermal management of the electronic components on the board.

4. Are there any special handling requirements for white PCBs?

Yes, white PCBs may show dirt, smudges, and fingerprints more easily than green PCBs. Extra care should be taken in handling and cleaning white PCBs during the manufacturing and assembly processes to maintain their clean and attractive appearance.

5. Can white PCBs be manufactured with the same surface finishes as green PCBs?

Yes, white PCBs can be manufactured with the same surface finishes as green PCBs, such as ENIG (immersion gold) and IAg (immersion silver). However, it is important to ensure that the chosen surface finish is compatible with the white solder mask and the soldering process to be used.

Conclusion

White PCBs offer a unique and visually appealing alternative to traditional green PCBs. With their clean and modern appearance, enhanced contrast, and improved thermal properties, white PCBs find applications in various industries, from consumer electronics to medical devices and industrial control systems. However, it is important to consider factors such as cost, availability, and manufacturing constraints when deciding to use white PCBs in a project.

By understanding the characteristics, advantages, and challenges of white PCBs, and by working with an experienced and reliable PCB manufacturer, designers and engineers can successfully incorporate white PCBs into their electronic devices and systems. With the right design considerations and manufacturing processes, white PCBs can provide a distinctive and high-quality solution for a wide range of applications.

No responses yet