Introduction to DIY PCB

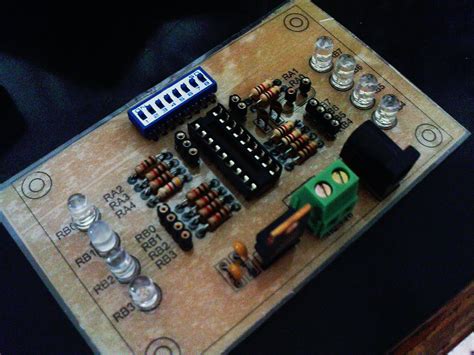

Printed Circuit Boards (PCBs) are the backbone of modern electronics. They provide a platform for mounting and connecting electronic components, allowing for the creation of complex circuits in a compact and organized manner. While PCBs are commonly manufactured in industrial settings, it is also possible to create your own PCBs at home using DIY techniques. In this article, we will explore the process of making homemade PCBs, providing a step-by-step guide for beginners who want to venture into the world of DIY electronics.

What is a PCB?

A PCB, or Printed Circuit Board, is a flat board made of insulating material, such as fiberglass or FR4, with conductive copper traces printed on its surface. These traces connect various electronic components, such as resistors, capacitors, and integrated circuits, to form a functional electronic circuit. PCBs provide a stable and reliable platform for electronic devices, ensuring proper connectivity and minimizing the risk of short circuits or loose connections.

Advantages of DIY PCB

Creating your own PCBs at home offers several advantages:

-

Cost-effective: Making your own PCBs can be significantly cheaper than ordering them from a professional manufacturer, especially for small-scale projects or prototypes.

-

Customization: DIY PCBs allow you to have complete control over the design and layout of your circuit board, enabling you to create custom solutions tailored to your specific needs.

-

Learning opportunity: Building your own PCBs is an excellent way to learn about electronics and gain hands-on experience in circuit design and fabrication.

-

Rapid prototyping: With DIY PCB techniques, you can quickly iterate on your designs and test new ideas without the need for long lead times associated with professional PCB manufacturing.

Tools and Materials Required

To get started with DIY PCB making, you will need the following tools and materials:

- Copper-clad board: A PCB substrate with a thin layer of copper on one or both sides.

- PCB design software: A computer program for designing the PCB layout, such as KiCad, Eagle, or EasyEDA.

- Laser printer: Used for printing the PCB design onto a transfer paper.

- Transfer paper: A special paper that allows the toner from the laser printer to be transferred onto the copper-clad board.

- Clothes iron: Used for transferring the toner from the transfer paper onto the copper-clad board.

- Etching solution: A chemical solution, typically ferric chloride, used to remove the unwanted copper from the board, leaving only the desired traces.

- Protective gear: Gloves, safety glasses, and a well-ventilated workspace to ensure your safety when handling chemicals.

- Drill or Dremel tool: Used for drilling holes in the PCB for mounting components and vias.

- Soldering iron and solder: Used for soldering components onto the completed PCB.

Step-by-Step Guide to Making a Homemade PCB

Step 1: Design Your PCB

The first step in creating a homemade PCB is to design your circuit using PCB design software. There are several free and open-source options available, such as KiCad and EasyEDA. These programs allow you to create schematic diagrams, define component footprints, and lay out the PCB traces.

When designing your PCB, consider the following factors:

- Component placement: Arrange the components in a logical and space-efficient manner, minimizing the distance between connected components to reduce signal integrity issues.

- Trace width: Choose appropriate trace widths based on the current requirements of your circuit. Wider traces can handle higher currents, while narrower traces are suitable for low-current signals.

- Ground plane: Incorporate a ground plane on one or both sides of the PCB to provide a low-impedance return path for signals and reduce electromagnetic interference (EMI).

- Silkscreen: Add text labels and component outlines to the silkscreen layer to aid in assembly and debugging.

Step 2: Print the PCB Design

Once your PCB design is complete, print the design onto a transfer paper using a laser printer. Make sure to print the design in mirror image, as it will be transferred onto the copper-clad board.

Step 3: Transfer the Design onto the Copper-Clad Board

Place the printed transfer paper onto the copper-clad board, with the toner side facing down. Use a clothes iron set to its highest temperature setting (without steam) to transfer the toner onto the copper surface. Apply firm and even pressure for several minutes, ensuring that the entire design is transferred properly.

Step 4: Etching the PCB

Prepare the etching solution according to the manufacturer’s instructions. Typically, this involves dissolving ferric chloride powder in water. Wear protective gloves and safety glasses when handling the etching solution.

Submerge the PCB into the etching solution, with the copper side facing up. Gently agitate the solution to ensure even etching. The etching process may take anywhere from a few minutes to an hour, depending on the strength of the solution and the size of the PCB.

Periodically check the progress of the etching process. Once the unwanted copper has been completely removed, leaving only the desired traces, remove the PCB from the solution and rinse it thoroughly with water.

Step 5: Drilling Holes and Soldering Components

Using a drill or Dremel tool, carefully drill holes in the PCB for mounting components and creating vias. Ensure that the drill bit size matches the component leads and via requirements.

Clean the PCB with isopropyl alcohol to remove any residues and prepare it for soldering. Place the components on the PCB according to your design and solder them in place using a soldering iron and solder. Pay attention to the component orientation and ensure that the solder joints are clean and secure.

Tips and Tricks for Successful DIY PCB Making

- Double-check your PCB design before printing to avoid costly mistakes.

- Use high-quality transfer paper and a laser printer for best results.

- Ensure proper ventilation when working with etching solutions and solder fumes.

- Test the continuity of traces and connections using a multimeter before soldering components.

- Practice proper soldering techniques to create reliable and durable connections.

Frequently Asked Questions (FAQ)

1. Can I use an inkjet printer instead of a laser printer for transferring the PCB design?

No, inkjet printers use liquid ink, which is not suitable for the toner transfer method. A laser printer is required as it uses toner, which can be effectively transferred onto the copper-clad board.

2. Are there any alternatives to ferric chloride for etching the PCB?

Yes, there are alternative etching solutions, such as ammonium persulfate and hydrogen peroxide with hydrochloric acid. However, ferric chloride is the most commonly used and readily available option.

3. Can I create double-sided PCBs using the DIY method?

Yes, it is possible to create double-sided PCBs using the toner transfer method. However, it requires careful alignment of the designs on both sides of the board and may be more challenging for beginners.

4. How can I create soldermask and silkscreen layers on my homemade PCB?

Creating soldermask and silkscreen layers at home can be more challenging. One option is to use special UV-sensitive soldermask and silkscreen inks that can be applied and cured using UV light. However, this process requires additional equipment and materials.

5. Are there any safety precautions I should take when making PCBs at home?

Yes, safety is paramount when working with chemicals and soldering equipment. Always wear protective gloves and safety glasses when handling etching solutions. Work in a well-ventilated area to avoid inhaling fumes from etching solutions and solder. Properly dispose of used etching solutions according to local regulations.

Conclusion

Creating your own PCBs at home is a rewarding and educational experience for electronics enthusiasts and hobbyists. By following the step-by-step guide outlined in this article, beginners can start their journey into the world of DIY PCB fabrication. With practice and patience, you can create custom PCBs for your projects, unleashing your creativity and bringing your electronic ideas to life.

Remember to prioritize safety, double-check your designs, and practice proper soldering techniques. As you gain experience, you can explore more advanced techniques and tackle more complex PCB designs.

Embrace the world of DIY electronics and enjoy the satisfaction of creating your own PCBs from scratch!

No responses yet