Table of Contents

- Introduction to I2C and SPI

- What is I2C?

- What is SPI?

- Key Differences between I2C and SPI

- Communication Type

- Number of Wires

- Speed

- Addressing

- Hardware Complexity

- Cost

- Noise Immunity

- Power Consumption

- When to Use I2C

- When to Use SPI

- Combining I2C and SPI

- FAQ

- Conclusion

Introduction to I2C and SPI

What is I2C?

I2C, pronounced “I-squared-C,” is a synchronous, multi-master, multi-slave, packet-switched, single-ended, serial computer bus invented by Philips Semiconductor (now NXP Semiconductors). It is typically used for attaching lower-speed peripheral ICs to processors and microcontrollers in short-distance, intra-board communication.

What is SPI?

SPI is a synchronous, full-duplex, master-slave-based communication protocol. It is used for short-distance communication, primarily in embedded systems. SPI devices communicate in full-duplex mode using a master-slave architecture with a single master.

Key Differences between I2C and SPI

Communication Type

I2C is a half-duplex communication protocol, which means data can be transmitted in both directions, but not simultaneously. In contrast, SPI is a full-duplex communication protocol, allowing data to be transmitted and received simultaneously.

Number of Wires

I2C uses two wires for communication: SDA (Serial Data) and SCL (Serial Clock). An additional wire is required for ground, and sometimes a power wire is used if the devices do not share a common power source.

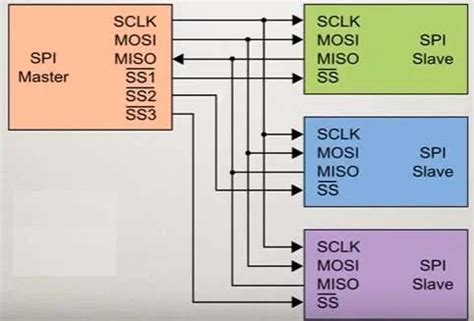

SPI, on the other hand, uses four wires: MOSI (Master Out Slave In), MISO (Master In Slave Out), SCLK (Serial Clock), and SS (Slave Select). Like I2C, SPI also requires a ground wire and may need a power wire if devices do not share a common power source.

| Protocol | Wires |

|---|---|

| I2C | SDA (Serial Data), SCL (Serial Clock), GND, (Optional) Power |

| SPI | MOSI, MISO, SCLK, SS, GND, (Optional) Power |

Speed

SPI is generally faster than I2C. I2C has a standard mode with a data rate of 100 kbit/s and a fast mode of 400 kbit/s. There are also high-speed modes that allow for data rates of 1 Mbit/s and 3.4 Mbit/s.

SPI, on the other hand, does not have a defined maximum speed. The maximum speed depends on the devices communicating and the length of the connecting wires. Typical SPI devices can communicate at speeds up to 10 Mbit/s, with some high-speed devices capable of speeds up to 100 Mbit/s.

| Protocol | Speed |

|---|---|

| I2C | Standard: 100 kbit/s, Fast: 400 kbit/s, High-Speed: 1-3.4 Mbit/s |

| SPI | Typical: Up to 10 Mbit/s, High-Speed: Up to 100 Mbit/s |

Addressing

I2C uses device addressing, which means each device on the bus has a unique address. The master initiates communication by sending the address of the slave device it wants to communicate with. This allows multiple slave devices to be connected to the same bus.

SPI does not have built-in addressing. The master selects the slave device it wants to communicate with using the SS (Slave Select) line. If multiple slave devices are connected, the master needs a separate SS line for each slave.

Hardware Complexity

I2C has a more complex hardware implementation compared to SPI. I2C requires pull-up resistors on the SDA and SCL lines, and the communication is based on open-drain/open-collector logic.

SPI has a simpler hardware implementation. It does not require pull-up resistors, and the communication is based on push-pull logic.

Cost

Due to its simpler hardware implementation, SPI tends to be less expensive than I2C. However, the cost difference is generally minimal and depends on the specific devices and application.

Noise Immunity

I2C has better noise immunity compared to SPI. The use of open-drain/open-collector logic and pull-up resistors helps to reduce the impact of noise on the communication lines.

SPI, with its push-pull logic, is more susceptible to noise. However, proper PCB design and signal integrity techniques can help mitigate noise issues.

Power Consumption

I2C typically has lower power consumption compared to SPI. The use of open-drain/open-collector logic allows for lower current consumption during communication.

SPI, with its push-pull logic, generally consumes more power. However, the power consumption difference between I2C and SPI is often negligible in most applications.

When to Use I2C

I2C is a good choice in the following scenarios:

- When you need to connect multiple slave devices to a single master

- When device addressing is required

- When lower data rates (up to 3.4 Mbit/s) are sufficient

- When you need better noise immunity

- When you have limited PCB space and want to minimize wiring

When to Use SPI

SPI is a good choice in the following scenarios:

- When you need high-speed data transfer (up to 100 Mbit/s)

- When you have a single master and one or a few slave devices

- When you need full-duplex communication

- When you have sufficient PCB space for additional wiring

- When you need a simpler hardware implementation

Combining I2C and SPI

In some cases, you may find it beneficial to use both I2C and SPI in the same system. For example, you can use I2C for slower peripherals like sensors and SPI for faster peripherals like displays or external memory. This allows you to optimize the communication based on the requirements of each device.

When combining I2C and SPI, ensure proper signal integrity and consider the power consumption and PCB layout requirements for each protocol.

FAQ

-

Can I2C and SPI devices communicate with each other directly?

No, I2C and SPI devices cannot communicate directly with each other. They use different communication protocols and have incompatible signal levels. If you need to connect an I2C device to an SPI device, you’ll need to use a bridge or converter IC. -

Is it possible to have multiple masters in an SPI system?

While SPI is designed for single-master systems, it is possible to have multiple masters. However, this requires additional hardware and software complexity to handle arbitration and avoid communication conflicts. -

What is the maximum number of devices that can be connected to an I2C bus?

Theoretically, the maximum number of devices on an I2C bus is limited by the 7-bit addressing scheme, which allows for 128 unique addresses. However, in practice, the maximum number of devices is limited by the bus capacitance and the strength of the pull-up resistors. Typical I2C buses can support up to 20-30 devices. -

Can I use longer wires for I2C and SPI communication?

Both I2C and SPI are designed for short-distance communication. Longer wires can introduce signal integrity issues, such as increased capacitance, noise, and signal reflections. If you need to communicate over longer distances, you may need to use specialized bus drivers, reduce the communication speed, or consider alternative communication protocols like RS-485. -

Are there any variations or extensions of the I2C and SPI protocols?

Yes, there are several variations and extensions of both I2C and SPI. For example, SMBus (System Management Bus) is a variant of I2C designed for power management and system monitoring. The MIDI (Musical Instrument Digital Interface) protocol is based on a simplified version of SPI. Some microcontrollers also offer proprietary extensions to SPI, such as Dual SPI and Quad SPI, which use additional data lines for faster data transfer.

Conclusion

Understanding the differences between I2C and SPI is crucial when designing embedded systems. Each protocol has its strengths and weaknesses, and the choice between them depends on factors such as communication speed, device addressing, hardware complexity, and noise immunity.

I2C is well-suited for applications that require multiple slave devices, lower data rates, and better noise immunity. SPI, on the other hand, is ideal for high-speed data transfer and simpler hardware implementations.

By carefully considering the requirements of your project and the characteristics of each protocol, you can make an informed decision and select the best communication interface for your needs. Remember that in some cases, using a combination of I2C and SPI can provide an optimal solution.

As you develop your embedded systems, keep in mind the key differences between I2C and SPI, and always refer to the datasheets of the devices you are using for specific implementation details and guidelines.

No responses yet