Introduction to MOSFET Testing

Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) are essential components in modern electronic circuits. They are widely used in various applications, including power electronics, automotive systems, and consumer devices. To ensure the proper functioning of these circuits, it is crucial to conduct effective MOSFET testing. In this comprehensive guide, we will explore the different methods and techniques for testing MOSFETs, helping you identify faulty components and maintain the reliability of your electronic systems.

Understanding MOSFETs

Before diving into MOSFET testing, it’s essential to understand the basic structure and operation of these devices. MOSFETs are voltage-controlled transistors that consist of three terminals: the gate, source, and drain. The gate terminal controls the flow of current between the source and drain terminals. MOSFETs can be classified into two main types:

- N-channel MOSFETs (NMOS): In an NMOS, the current flows from the drain to the source when a positive voltage is applied to the gate.

- P-channel MOSFETs (PMOS): In a PMOS, the current flows from the source to the drain when a negative voltage is applied to the gate.

MOSFETs operate in three main regions:

- Cut-off region: When the gate-to-source voltage (VGS) is below the threshold voltage (VTH), the MOSFET is in the cut-off region, and no current flows between the drain and source.

- Linear region: When VGS exceeds VTH, the MOSFET enters the linear region, and the drain current (ID) increases linearly with the drain-to-source voltage (VDS).

- Saturation region: As VDS increases further, the MOSFET enters the saturation region, where ID remains relatively constant, regardless of changes in VDS.

MOSFET Testing Equipment

To effectively test MOSFETs, you will need the following equipment:

- Digital Multimeter (DMM): A DMM is a versatile tool that can measure voltage, current, and resistance. It is essential for conducting various MOSFET tests.

- Oscilloscope: An oscilloscope allows you to visualize and analyze the waveforms of voltage and current signals in a MOSFET circuit.

- Function Generator: A function generator provides variable frequency and amplitude signals for testing the dynamic performance of MOSFETs.

- Power Supply: A stable power supply is necessary to provide the required voltages for MOSFET testing.

- Breadboard or Test Fixture: A breadboard or test fixture helps in creating temporary circuits for MOSFET testing.

Visual Inspection

Before conducting electrical tests, it’s crucial to perform a visual inspection of the MOSFET. This step can help identify any obvious physical damage or defects that may affect the device’s performance. Here are some key aspects to check during a visual inspection:

- Package integrity: Look for cracks, chips, or other damage to the MOSFET package.

- Lead condition: Check for bent, broken, or corroded leads.

- Marking legibility: Ensure that the MOSFET markings are clear and readable.

- Contamination: Inspect for any signs of contamination, such as dirt, dust, or foreign particles, on the device.

If any issues are found during the visual inspection, it’s best to replace the MOSFET before proceeding with electrical tests.

Continuity Test

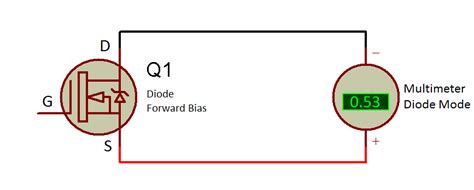

The continuity test is a simple but essential test that checks for short circuits or open circuits in the MOSFET. To perform a continuity test, follow these steps:

- Set your DMM to the continuity or diode test mode.

- Connect the DMM’s black probe to the MOSFET’s source terminal and the red probe to the drain terminal.

- The DMM should indicate an open circuit (high resistance or no continuity). If it shows a short circuit (low resistance or continuity), the MOSFET is likely faulty.

- Repeat the test between the gate and source terminals, and then between the gate and drain terminals. In both cases, the DMM should indicate an open circuit.

If any short circuits are detected during the continuity test, the MOSFET should be replaced.

Gate Threshold Voltage Test

The gate threshold voltage (VTH) is the minimum voltage required at the gate terminal to create a conducting channel between the source and drain terminals. Testing the VTH is crucial to ensure that the MOSFET is operating within its specified range. To measure the VTH, follow these steps:

- Set up a test circuit with the MOSFET, a Variable Power Supply, and a DMM.

- Connect the MOSFET’s source terminal to ground and the drain terminal to a resistor in series with the positive terminal of the power supply.

- Connect the DMM across the resistor to measure the drain current (ID).

- Gradually increase the voltage at the gate terminal until you observe a small drain current (typically around 1 mA).

- The gate voltage at which the drain current starts to flow is the gate threshold voltage (VTH).

Compare the measured VTH with the manufacturer’s specified value to determine if the MOSFET is functioning correctly.

Drain-Source On-Resistance Test

The drain-source on-resistance (RDS(on)) is the resistance between the drain and source terminals when the MOSFET is fully turned on. A low RDS(on) is desirable for efficient power dissipation and minimizing voltage drop across the MOSFET. To measure RDS(on), follow these steps:

- Set up a test circuit with the MOSFET, a power supply, and a DMM.

- Apply a sufficient gate voltage to fully turn on the MOSFET (typically 10V or more above the VTH).

- Apply a small drain-source voltage (VDS) and measure the resulting drain current (ID) using the DMM.

- Calculate RDS(on) using Ohm’s law: RDS(on) = VDS / ID.

Compare the measured RDS(on) with the manufacturer’s specified value to ensure the MOSFET is performing as expected.

Dynamic Tests

Dynamic tests assess the MOSFET’s performance under varying voltage and current conditions. These tests help evaluate the device’s switching speed, capacitance, and overall dynamic behavior. Some common dynamic tests include:

- Gate Charge Test: This test measures the amount of charge required to turn on the MOSFET, which directly affects the device’s switching speed.

- Capacitance Test: MOSFET capacitances, such as input capacitance (Ciss) and output capacitance (Coss), influence the device’s switching performance and power efficiency.

- Switching Time Test: This test measures the time required for the MOSFET to transition between the on and off states, which is critical for high-frequency applications.

To conduct dynamic tests, you will typically need an oscilloscope and a function generator in addition to the basic testing equipment.

Interpreting Test Results

After conducting various MOSFET tests, it’s essential to interpret the results correctly to determine the device’s health and performance. Compare the measured values with the manufacturer’s specifications and datasheets. If the MOSFET’s characteristics deviate significantly from the expected values, it may indicate a faulty or degraded device.

Some common issues that can be identified through MOSFET testing include:

- Short circuits: If the continuity test reveals a short circuit between any of the terminals, the MOSFET is likely damaged and should be replaced.

- Abnormal VTH: If the measured VTH is significantly different from the specified value, it may indicate a faulty MOSFET or a shift in the device’s characteristics due to aging or stress.

- High RDS(on): An abnormally high RDS(on) can lead to increased power dissipation and reduced efficiency. It may signify a degraded or damaged MOSFET.

- Poor dynamic performance: If the dynamic tests reveal slow switching times or abnormal capacitance values, the MOSFET may not be suitable for high-frequency or high-speed applications.

By carefully analyzing the test results and comparing them with the expected values, you can identify faulty MOSFETs and take appropriate actions to maintain the reliability and performance of your electronic systems.

Safety Precautions

When testing MOSFETs, it’s crucial to follow proper safety precautions to protect yourself and the equipment. Some key safety guidelines include:

- Always wear appropriate personal protective equipment (PPE), such as safety glasses and gloves, when handling MOSFETs.

- Ensure that the testing equipment is properly grounded and calibrated before use.

- Be aware of the maximum voltage and current ratings of the MOSFET and the testing equipment, and never exceed these limits.

- Discharge any capacitors in the circuit before handling the MOSFET to prevent electric shock.

- Work in a well-ventilated area and avoid touching exposed conductors or terminals.

By following these safety precautions, you can minimize the risk of injury and damage to the equipment during MOSFET testing.

Frequently Asked Questions (FAQ)

-

Q: Can I test a MOSFET without removing it from the circuit?

A: While it is possible to test a MOSFET in-circuit, it is generally recommended to remove the device from the circuit for accurate testing. In-circuit testing may be affected by other components connected to the MOSFET, leading to inaccurate results. -

Q: How do I identify the gate, source, and drain terminals of a MOSFET?

A: The terminal identification of a MOSFET depends on the package type and the manufacturer. Refer to the device’s datasheet or consult the manufacturer’s website for the specific pinout information. In general, the gate terminal is usually isolated from the source and drain terminals, while the source and drain terminals are often symmetrical. -

Q: What should I do if I suspect a MOSFET is faulty but the tests show normal results?

A: If you suspect a MOSFET is faulty despite normal test results, it’s possible that the device is experiencing intermittent issues or is sensitive to specific operating conditions. In such cases, you may need to perform more advanced tests, such as thermal imaging or dynamic tests under varying loads and temperatures. It’s also a good idea to cross-check the MOSFET with a known good device to rule out any testing discrepancies. -

Q: Can I use a transistor tester to test MOSFETs?

A: Yes, many modern transistor testers are capable of testing MOSFETs in addition to bipolar junction transistors (BJTs). These testers can quickly identify the MOSFET type (N-channel or P-channel), measure the gate threshold voltage, and check for short circuits or open circuits. However, for more comprehensive testing, it’s recommended to use dedicated MOSFET testing equipment and follow the procedures outlined in this guide. -

Q: How often should I test MOSFETs in my electronic systems?

A: The frequency of MOSFET testing depends on various factors, such as the application, operating conditions, and the criticality of the system. In general, it’s a good practice to test MOSFETs during the initial design and prototyping stages, as well as during routine maintenance or troubleshooting. If your system operates in harsh environments or is subject to high stress levels, more frequent testing may be necessary to ensure the MOSFETs are performing as expected and to identify any potential issues before they lead to system failures.

Conclusion

Effective MOSFET testing is essential for ensuring the reliability and performance of electronic systems. By understanding the different types of tests, such as visual inspection, continuity test, gate threshold voltage test, drain-source on-resistance test, and dynamic tests, you can comprehensively assess the health and functionality of MOSFETs. Properly interpreting the test results and comparing them with the manufacturer’s specifications will help you identify faulty devices and take appropriate actions to maintain the integrity of your electronic circuits.

Remember to always prioritize safety when testing MOSFETs by following proper safety precautions and using appropriate testing equipment. Regularly testing MOSFETs and staying informed about the latest testing techniques and best practices will contribute to the long-term success and reliability of your electronic projects.

No responses yet