Consumer Electronics

Consumer electronics is one of the most significant markets for PCBs. This category includes devices such as smartphones, tablets, laptops, televisions, and home appliances. PCBs in consumer electronics are designed to be compact, lightweight, and cost-effective while delivering high performance and reliability.

| Device | PCB Characteristics |

|---|---|

| Smartphone | Multi-layer, high-density, flexible, RF-compatible |

| Tablet | Multi-layer, high-density, rigid-flex |

| Laptop | Multi-layer, high-density, rigid, high-speed |

| Television | Multi-layer, high-density, rigid, high-power |

| Home Appliance | Single or double-layer, low-density, rigid, cost-effective |

Consumer electronics PCBs often feature advanced technologies such as high-density interconnects (HDI), embedded components, and flexible circuits to accommodate the ever-increasing demand for smaller, more feature-rich devices.

Automotive Electronics

The automotive industry has seen a significant increase in the use of electronic systems, driving the demand for automotive-grade PCBs. These PCBs must withstand harsh environmental conditions, including extreme temperatures, vibrations, and exposure to chemicals, while maintaining high reliability and safety standards.

| Application | PCB Characteristics |

|---|---|

| Engine Control Unit | Multi-layer, high-density, rigid, high-temperature resistant |

| Infotainment System | Multi-layer, high-density, rigid-flex, high-speed |

| ADAS Sensors | Multi-layer, high-density, rigid-flex, RF-compatible |

| Lighting Systems | Single or double-layer, low-density, rigid, high-power |

Automotive PCBs often incorporate special materials and coatings to enhance their durability and resistance to environmental stressors. Additionally, they must comply with stringent industry standards, such as AEC-Q100, to ensure the highest level of quality and reliability.

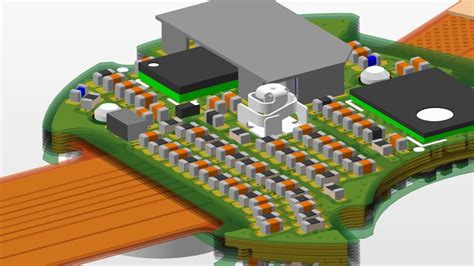

Industrial Electronics

Industrial electronics encompasses a wide range of applications, from process control and automation to power distribution and renewable energy systems. PCBs in this sector must be designed to operate reliably in demanding industrial environments, often featuring high-power handling capabilities, robust construction, and resistance to electromagnetic interference (EMI).

| Application | PCB Characteristics |

|---|---|

| Motor Drives | Multi-layer, high-power, rigid, high-temperature resistant |

| PLC Modules | Multi-layer, high-density, rigid, EMI-shielded |

| Power Supplies | Multi-layer, high-power, rigid, high-voltage resistant |

| Sensor Interfaces | Multi-layer, low-density, rigid-flex, EMI-shielded |

Industrial PCBs often utilize thicker copper traces and planes to handle higher currents and dissipate heat more effectively. They may also incorporate advanced thermal management techniques, such as metal-core substrates or heat sinks, to ensure optimal performance in high-temperature environments.

Medical Electronics

Medical electronics PCBs are used in a variety of applications, from diagnostic imaging equipment and patient monitoring systems to implantable devices and surgical instruments. These PCBs must adhere to strict regulatory requirements, such as ISO 13485 and FDA regulations, to ensure patient safety and device efficacy.

| Application | PCB Characteristics |

|---|---|

| MRI Scanners | Multi-layer, high-density, rigid, RF-compatible, low-leakage |

| Patient Monitors | Multi-layer, high-density, rigid-flex, low-noise |

| Implantable Devices | Multi-layer, high-density, flexible, biocompatible |

| Surgical Instruments | Single or double-layer, low-density, rigid, sterilizable |

Medical PCBs often require specialized materials and manufacturing processes to meet the stringent cleanliness and biocompatibility requirements. Additionally, they must be designed with high noise immunity and low electromagnetic emissions to prevent interference with other medical equipment.

Aerospace and Defense Electronics

Aerospace and defense electronics demand the highest level of performance, reliability, and durability from their PCBs. These applications often involve extreme environmental conditions, such as high altitudes, rapid temperature changes, and exposure to radiation, necessitating the use of specialized materials and manufacturing techniques.

| Application | PCB Characteristics |

|---|---|

| Avionics Systems | Multi-layer, high-density, rigid, high-speed, high-reliability |

| Radar Systems | Multi-layer, high-density, rigid-flex, RF-compatible, high-power |

| Satellite Communications | Multi-layer, high-density, rigid-flex, RF-compatible, radiation-hardened |

| Guidance and Navigation | Multi-layer, high-density, rigid, high-reliability, EMI-shielded |

Aerospace and defense PCBs often incorporate advanced materials, such as polyimide or PTFE laminates, to provide superior thermal and mechanical properties. They may also utilize specialized coatings and encapsulants to protect against moisture, dust, and other environmental hazards.

Telecommunications and Networking

Telecommunications and networking applications require PCBs that can handle high-speed data transmission, complex signal processing, and dense interconnectivity. These PCBs must also be designed to minimize signal integrity issues, such as crosstalk and impedance mismatch, to ensure optimal system performance.

| Application | PCB Characteristics |

|---|---|

| Routers and Switches | Multi-layer, high-density, rigid, high-speed, low-latency |

| Optical Transceivers | Multi-layer, high-density, rigid-flex, RF-compatible, high-bandwidth |

| 5G Base Stations | Multi-layer, high-density, rigid, RF-compatible, high-power |

| Data Center Equipment | Multi-layer, high-density, rigid, high-speed, high-reliability |

Telecommunications and networking PCBs often utilize advanced manufacturing techniques, such as microvias and fine-pitch BGAs, to achieve the required signal integrity and interconnect density. They may also incorporate specialized materials, such as low-loss dielectrics and ultra-smooth copper foils, to minimize signal attenuation and distortion.

FAQ

-

Q: What are the main factors to consider when selecting a PCB for a specific application?

A: When choosing a PCB for a specific application, consider factors such as the operating environment, required performance, size constraints, cost, and regulatory requirements. Additionally, evaluate the PCB’s layer count, material selection, and manufacturing complexity to ensure it meets the application’s needs. -

Q: How do PCBs in consumer electronics differ from those in industrial applications?

A: PCBs in consumer electronics prioritize compactness, light weight, and cost-effectiveness, while industrial PCBs focus on durability, high-power handling, and resistance to harsh environments. Consumer electronics PCBs often feature advanced technologies like HDI and flexible circuits, while industrial PCBs utilize thicker copper and robust construction. -

Q: What special considerations are required for medical electronics PCBs?

A: Medical electronics PCBs must adhere to strict regulatory requirements for patient safety and device efficacy. They require specialized materials and manufacturing processes to ensure cleanliness and biocompatibility, and must be designed with high noise immunity and low electromagnetic emissions to prevent interference with other medical equipment. -

Q: How do aerospace and defense PCBs differ from other applications?

A: Aerospace and defense PCBs are designed to withstand extreme environmental conditions, such as high altitudes, rapid temperature changes, and exposure to radiation. They often incorporate advanced materials and specialized coatings to provide superior thermal and mechanical properties, as well as protection against environmental hazards. -

Q: What are the key challenges in designing PCBs for telecommunications and networking applications?

A: The main challenges in designing PCBs for telecommunications and networking applications include managing high-speed data transmission, minimizing signal integrity issues (such as crosstalk and impedance mismatch), and achieving dense interconnectivity. These PCBs must utilize advanced manufacturing techniques and specialized materials to ensure optimal system performance.

In conclusion, PCBs play a crucial role in enabling the functionality and performance of electronic devices across various industries. By understanding the unique requirements and challenges of each application, designers and manufacturers can create PCBs that meet the specific needs of their target market, ensuring the highest level of quality, reliability, and performance.

No responses yet