Introduction to Ceramic PCB

Ceramic Printed Circuit Boards (PCBs) are a specialized type of PCB that utilizes ceramic materials as the substrate instead of the more commonly used FR-4 or other organic materials. Ceramic PCBs offer unique properties that make them ideal for certain applications, particularly in high-frequency, high-temperature, and high-reliability environments. In this comprehensive article, we will delve into the world of ceramic PCBs, exploring their composition, manufacturing process, advantages, disadvantages, and various applications.

What is a Ceramic PCB?

A ceramic PCB is a printed circuit board that uses a ceramic material, typically aluminum oxide (Al2O3) or aluminum nitride (AlN), as the base substrate. The ceramic substrate is then coated with a conductive layer, usually copper, to form the circuit pattern. Ceramic PCBs are known for their excellent thermal conductivity, low dielectric loss, and high resistivity, making them suitable for demanding applications.

Composition of Ceramic PCBs

Ceramic PCBs are composed of two main components:

- Ceramic Substrate:

- Aluminum Oxide (Al2O3): Al2O3 is the most widely used ceramic substrate due to its excellent electrical insulation properties, good thermal conductivity, and mechanical strength.

-

Aluminum Nitride (AlN): AlN offers even better thermal conductivity than Al2O3 and is often used in high-power applications that require efficient heat dissipation.

-

Conductive Layer:

- Copper: Copper is the most common conductive material used in ceramic PCBs. It is applied to the ceramic substrate through various methods, such as thick film printing, thin film deposition, or direct bonding.

Manufacturing Process of Ceramic PCBs

The manufacturing process of ceramic PCBs differs from that of traditional FR-4 PCBs. Here are the key steps involved:

- Substrate Preparation:

-

The ceramic substrate, either Al2O3 or AlN, is cleaned and prepared for the application of the conductive layer.

-

Conductive Layer Application:

- Thick Film Printing: A conductive paste, usually containing silver or copper, is screen printed onto the ceramic substrate and then fired at high temperatures to form a strong bond.

- Thin Film Deposition: A thin layer of copper is deposited onto the ceramic substrate using techniques like sputtering or evaporation.

-

Direct Bonding: A copper foil is directly bonded to the ceramic substrate using high temperature and pressure.

-

Circuit Patterning:

-

The desired circuit pattern is created on the conductive layer using photolithography and etching processes.

-

Drilling and Plating:

- Holes are drilled in the ceramic PCB for component placement and interconnections.

-

The holes are then plated with copper to establish electrical connectivity between layers.

-

Surface Finishing:

-

A surface finish, such as nickel/gold (ENIG) or silver, is applied to the exposed copper traces to protect them from oxidation and enhance solderability.

-

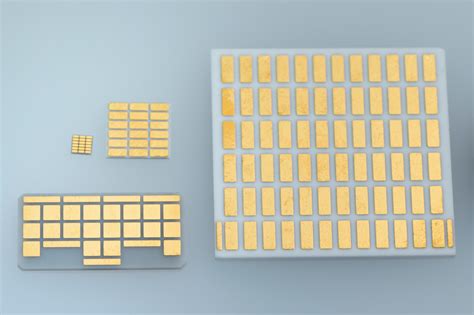

Singulation:

- The ceramic PCB Panel is cut into individual boards using specialized tools like laser cutters or diamond saws.

Advantages of Ceramic PCBs

Ceramic PCBs offer several advantages over traditional FR-4 PCBs:

- Excellent Thermal Conductivity:

- Ceramic materials like Al2O3 and AlN have high thermal conductivity, allowing efficient heat dissipation from components.

-

This property makes ceramic PCBs suitable for high-power applications and helps in maintaining stable performance over a wide temperature range.

-

Low Dielectric Loss:

- Ceramic substrates have low dielectric loss, which means they exhibit minimal signal loss and distortion at high frequencies.

-

This characteristic is particularly important for high-frequency applications, such as RF and microwave circuits.

-

High Resistivity:

- Ceramic materials have high electrical resistivity, providing excellent electrical insulation between conductive layers.

-

This property helps in reducing crosstalk and signal interference, ensuring signal integrity.

-

Mechanical Strength:

- Ceramic PCBs are inherently strong and rigid, offering better mechanical stability compared to FR-4 PCBs.

-

This strength enables ceramic PCBs to withstand harsh environments, vibrations, and physical stresses.

-

Dimensional Stability:

- Ceramic substrates have a low coefficient of thermal expansion (CTE), which means they experience minimal dimensional changes with temperature variations.

- This stability is crucial for maintaining precise component alignment and preventing thermal stress-related failures.

Disadvantages of Ceramic PCBs

Despite their numerous advantages, ceramic PCBs also have some limitations:

- Higher Cost:

- Ceramic PCBs are generally more expensive than FR-4 PCBs due to the specialized materials and manufacturing processes involved.

-

The higher cost may limit their use to applications where the unique properties of ceramic PCBs are essential.

-

Limited Design Flexibility:

- Ceramic PCBs have limitations in terms of minimum feature sizes, layer count, and hole sizes compared to FR-4 PCBs.

-

These limitations can restrict the complexity and density of circuit designs that can be achieved with ceramic PCBs.

-

Brittle Nature:

- Ceramic materials are inherently brittle, making ceramic PCBs more susceptible to cracking or shattering under excessive mechanical stress or impact.

-

Proper handling and mounting techniques are necessary to avoid damage to ceramic PCBs.

-

Manufacturing Challenges:

- The manufacturing process of ceramic PCBs is more complex and requires specialized equipment and expertise compared to FR-4 PCBs.

- This complexity can lead to longer lead times and potential manufacturing challenges, especially for intricate designs.

Applications of Ceramic PCBs

Ceramic PCBs find applications in various industries and sectors where their unique properties are advantageous:

- High-Frequency Electronics:

- RF and microwave circuits

- Satellite communications

- Radar systems

-

Wireless base stations

-

Power Electronics:

- High-power LED lighting

- Power converters and inverters

- Motor drives

-

Electric vehicle power systems

-

Aerospace and Defense:

- Avionics systems

- Missile guidance systems

- Radar and surveillance equipment

-

Satellite components

-

Medical Devices:

- High-frequency medical imaging (MRI, CT, ultrasound)

- Implantable devices

- Surgical instruments

-

Medical lasers

-

Industrial and Automotive:

- High-Temperature Sensors and controls

- Engine management systems

- Welding equipment

- Oil and gas exploration devices

Ceramic PCB vs. FR-4 PCB: A Comparison

To understand the differences between ceramic PCBs and traditional FR-4 PCBs, let’s compare their key properties:

| Property | Ceramic PCB | FR-4 PCB |

|---|---|---|

| Thermal Conductivity | High (20-200 W/mK) | Low (0.3-0.4 W/mK) |

| Dielectric Constant | Low (6-10) | Higher (4.5-4.7) |

| Dielectric Loss | Low (0.001-0.002) | Higher (0.02-0.03) |

| Electrical Resistivity | High (>1014 Ω·cm) | Lower (1010-1012 Ω·cm) |

| Mechanical Strength | High | Moderate |

| Dimensional Stability | High | Moderate |

| Cost | Higher | Lower |

| Design Flexibility | Limited | High |

As evident from the comparison, ceramic PCBs excel in thermal conductivity, dielectric properties, and mechanical strength, making them suitable for high-performance applications. However, FR-4 PCBs offer better cost-effectiveness and design flexibility for general-purpose electronics.

Frequently Asked Questions (FAQ)

-

Q: Can ceramic PCBs be used for multilayer designs?

A: Yes, ceramic PCBs can be fabricated with multiple layers, although the layer count is typically lower compared to FR-4 PCBs due to manufacturing limitations. -

Q: Are ceramic PCBs suitable for high-voltage applications?

A: Yes, ceramic PCBs are well-suited for high-voltage applications due to their excellent electrical insulation properties and high dielectric strength. -

Q: How do ceramic PCBs handle thermal management?

A: Ceramic PCBs have high thermal conductivity, which allows efficient heat dissipation from components. They can effectively spread heat and maintain stable performance in high-temperature environments. -

Q: Can ceramic PCBs be soldered using conventional methods?

A: Yes, ceramic PCBs can be soldered using standard soldering techniques, such as reflow soldering or Wave Soldering. However, proper temperature control and soldering profiles are essential to avoid thermal stress on the ceramic substrate. -

Q: Are ceramic PCBs environmentally friendly?

A: Ceramic PCBs are considered more environmentally friendly compared to FR-4 PCBs because they do not contain brominated flame retardants (BFRs) or other harmful chemicals commonly used in FR-4 laminates. However, the manufacturing process of ceramic PCBs still has some environmental impact, and proper disposal methods should be followed.

Conclusion

Ceramic PCBs offer a unique combination of properties that make them ideal for high-performance applications where thermal management, low dielectric loss, and high reliability are critical. Their excellent thermal conductivity, high resistivity, and mechanical strength enable them to outperform traditional FR-4 PCBs in demanding environments. However, the higher cost and limited design flexibility of ceramic PCBs should be considered when evaluating their suitability for a specific application.

As technology continues to advance, ceramic PCBs are expected to play a crucial role in enabling the development of cutting-edge electronics in fields such as 5G communications, electric vehicles, and aerospace systems. Understanding the characteristics, manufacturing process, and applications of ceramic PCBs is essential for designers and engineers to leverage their potential and push the boundaries of electronic performance.

No responses yet