Introduction to Voltage Converters

In the world of electrical engineering, voltage converters play a crucial role in adapting electrical devices to different power supply requirements. A voltage converter is an electronic circuit that changes the voltage level of an electrical power source to a different level, making it compatible with the device being powered. One common example is a 24v to 12v converter, which is used to step down the voltage from a 24-volt power source to a 12-volt level, suitable for devices that require a lower voltage.

Types of Voltage Converters

There are several types of voltage converters, each with its own characteristics and applications. The main types include:

- Linear voltage converters

- Switching voltage converters

- Boost Converters

- Buck converters

- Flyback converters

Linear Voltage Converters

Linear voltage converters use a series of resistors or a voltage divider network to reduce the voltage level. They are simple, inexpensive, and suitable for low-power applications. However, they have poor efficiency and generate significant heat, making them less suitable for high-power applications.

Switching Voltage Converters

Switching voltage converters use a combination of switches, inductors, and capacitors to efficiently convert voltage levels. They operate by rapidly switching the input voltage on and off, using pulse-width modulation (PWM) to control the output voltage. Switching converters are more efficient than linear converters and can handle higher power levels.

Boost Converters

Boost converters, also known as step-up converters, are used to increase the voltage level from a lower input voltage to a higher output voltage. They work by storing energy in an inductor when the switch is closed and releasing it to the output when the switch is opened. Boost converters are commonly used in battery-powered devices, solar power systems, and LED drivers.

Buck Converters

Buck converters, also known as step-down converters, are used to decrease the voltage level from a higher input voltage to a lower output voltage. They work by alternately connecting and disconnecting the input voltage to an inductor, which stores and releases energy to the output. Buck converters are widely used in computer power supplies, automotive systems, and DC motor control.

Flyback Converters

Flyback converters are a type of isolated switching converter that can provide voltage step-up, step-down, or inversion. They use a transformer to provide galvanic isolation between the input and output, making them suitable for applications that require electrical isolation. Flyback converters are commonly used in switch-mode power supplies, battery chargers, and off-line power supplies.

24v to 12v Converter Circuit Design

A 24v to 12v converter is a step-down voltage converter that reduces the voltage from 24 volts to 12 volts. There are several approaches to designing a 24v to 12v converter circuit, each with its own advantages and limitations.

Linear Voltage Regulator-Based 24v to 12v Converter

One simple approach to designing a 24v to 12v converter is to use a linear voltage regulator, such as the popular 7812 IC. The 7812 is a fixed-output, positive voltage regulator that provides a stable 12-volt output from an input voltage range of 14.5 to 35 volts.

Here’s a basic circuit diagram for a 24v to 12v converter using a 7812 voltage regulator:

24V Input------|>|-----+-------+-----+-------- +12V Output

| | |

| 7812 |

| | |

+-------+-----+

|

|

|

|

GND----------------------------|

In this circuit, the 24-volt input is connected to the input pin of the 7812 regulator through a protective diode. The diode prevents reverse polarity damage to the regulator. The output pin of the 7812 provides a stable 12-volt output, while the ground pin is connected to the common ground.

Although this circuit is simple and easy to implement, it has some limitations:

- Low efficiency: Linear regulators dissipate the excess voltage as heat, resulting in poor efficiency, especially when the input voltage is significantly higher than the output voltage.

- Heat generation: Due to the low efficiency, linear regulators generate significant heat, which may require a heat sink for proper thermal management.

- Limited current capacity: The maximum output current of a linear regulator is limited by its power dissipation capability and the available heat sinking.

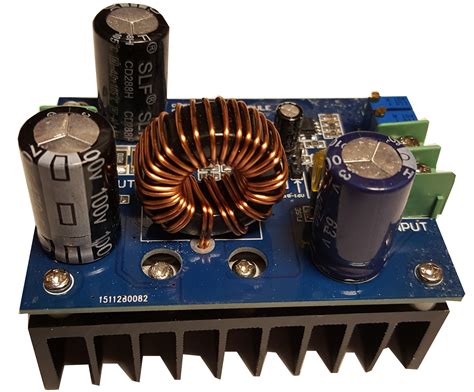

Switching Converter-Based 24v to 12v Converter

A more efficient approach to designing a 24v to 12v converter is to use a switching converter, such as a buck converter. Buck converters use a combination of switches, inductors, and capacitors to step down the voltage while maintaining high efficiency.

Here’s a basic circuit diagram for a 24v to 12v converter using a buck converter:

24V Input---+---+-------+---+-------+-----+-------- +12V Output

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| +-------+ +-------+ |

| | |

| | |

| | |

| | |

GND---------+---------------+-------------+

In this circuit, the 24-volt input is connected to the input of the buck converter. The buck converter consists of a high-side switch (usually a MOSFET), a low-side switch (another MOSFET or a diode), an inductor, and an output capacitor. The switches are controlled by a PWM signal, which determines the duty cycle and, consequently, the output voltage.

When the high-side switch is on, current flows from the input through the inductor, storing energy in its magnetic field. When the high-side switch turns off, the low-side switch turns on, providing a path for the inductor current to continue flowing, releasing its stored energy to the output capacitor and the load.

By adjusting the duty cycle of the PWM signal, the output voltage can be regulated to the desired 12-volt level. The inductor and output capacitor help to filter the output voltage, reducing ripple and providing a stable voltage to the load.

Switching converters offer several advantages over linear regulators:

- High efficiency: Switching converters can achieve efficiencies of 80% to 95%, reducing heat generation and power losses.

- Compact size: Due to their high efficiency, switching converters require smaller heat sinks and can be designed in more compact form factors.

- Higher current capacity: Switching converters can handle higher output currents than linear regulators, making them suitable for high-power applications.

However, switching converters also have some disadvantages:

- Complexity: Switching converters are more complex than linear regulators, requiring careful design and component selection.

- Electromagnetic interference (EMI): The high-frequency switching in converters can generate EMI, which may require additional filtering and shielding.

- Higher cost: Due to their complexity and additional components, switching converters are generally more expensive than linear regulators.

Selecting Components for a 24v to 12v Converter

When designing a 24v to 12v converter, it’s essential to select appropriate components to ensure reliable operation, efficiency, and performance. Here are some key components to consider:

Voltage Regulator or Controller IC

For a linear regulator-based converter, choose a voltage regulator IC with the following characteristics:

- Fixed 12-volt output

- Input voltage range covering 24 volts

- Adequate output current rating for your application

- Low dropout voltage for better efficiency

- Built-in protection features (e.g., thermal shutdown, short-circuit protection)

For a switching converter-based design, select a controller IC or a complete switching regulator module with the following features:

- Adjustable or fixed 12-volt output

- Input voltage range covering 24 volts

- Sufficient output current rating

- High efficiency

- Built-in protection features (e.g., over-current, over-voltage, thermal shutdown)

- Compatibility with your chosen switching topology (e.g., buck, boost, flyback)

Switches (MOSFETs or Diodes)

In switching converters, the choice of switches is critical for efficiency and performance. When selecting MOSFETs, consider the following factors:

- Voltage rating: The MOSFET should have a voltage rating higher than the maximum input voltage, with a sufficient safety margin.

- Current rating: The MOSFET should be able to handle the peak and continuous current in your application.

- On-resistance (RDS(on)): Lower RDS(on) results in lower conduction losses and higher efficiency.

- Switching speed: Faster switching speeds reduce switching losses but may increase EMI.

For the low-side switch, you can use a diode or a synchronous MOSFET. Schottky diodes are commonly used due to their low forward voltage drop and fast switching speed.

Inductors and Capacitors

The selection of inductors and capacitors in a switching converter affects the output voltage ripple, transient response, and overall stability of the converter.

When choosing an inductor, consider the following factors:

- Inductance value: The inductance should be selected based on the switching frequency, output voltage, and ripple current requirements.

- Current rating: The inductor should be able to handle the peak and RMS currents without saturating or overheating.

- DC resistance (DCR): Lower DCR results in lower conduction losses and higher efficiency.

For the output capacitor, consider these factors:

- Capacitance value: The capacitance should be chosen to meet the output voltage ripple and transient response requirements.

- Voltage rating: The capacitor should have a voltage rating higher than the maximum output voltage, with a sufficient safety margin.

- Equivalent series resistance (ESR): Lower ESR results in lower ripple voltage and better transient response.

PCB Layout Considerations for 24v to 12v Converters

Proper PCB layout is crucial for the performance, efficiency, and reliability of a 24v to 12v converter. Here are some key considerations:

- Minimize loop areas: Keep the high-current loops (e.g., input capacitor to switch, switch to inductor) as small as possible to reduce stray inductance and minimize EMI.

- Use wide traces: Use sufficiently wide traces for high-current paths to minimize resistive losses and ensure good heat dissipation.

- Provide adequate grounding: Use a solid ground plane and multiple vias to provide a low-impedance return path for high-frequency currents.

- Separate sensitive signals: Keep sensitive analog and control signals away from high-current and high-frequency paths to avoid interference.

- Use proper decoupling: Place decoupling capacitors close to the IC power pins to reduce noise and ensure stable operation.

- Consider thermal management: Provide sufficient copper area and thermal vias for heat-generating components, such as voltage regulators and switches, to ensure proper heat dissipation.

Testing and Troubleshooting 24v to 12v Converters

After assembling the 24v to 12v converter, it’s essential to test and troubleshoot the circuit to ensure proper operation and identify any issues. Here are some steps to follow:

- Visual inspection: Carefully inspect the PCB for any soldering defects, short circuits, or damaged components.

- Continuity test: Use a multimeter to check for continuity between key points in the circuit, such as input to output, ground to ground, and switch connections.

- Power-on test: Apply the 24-volt input to the converter and measure the output voltage. Verify that the output voltage is close to the desired 12-volt level and is stable.

- Load test: Connect a load to the output of the converter and measure the output voltage and current. Ensure that the converter maintains the desired output voltage under various load conditions.

- Efficiency measurement: Measure the input and output power of the converter under different load conditions to calculate the efficiency. Compare the measured efficiency with the expected values based on the component specifications.

If any issues are found during testing, troubleshoot the circuit using the following steps:

- Check the input voltage: Verify that the input voltage is within the specified range and is free from noise or fluctuations.

- Check the component values: Ensure that the components (e.g., resistors, capacitors, inductors) have the correct values and are properly connected.

- Check the control signals: Verify that the control signals (e.g., PWM, enable) are properly generated and applied to the converter.

- Check for overheating: Monitor the temperature of the components, especially the voltage regulator, switches, and inductor. Overheating may indicate excessive power dissipation or inadequate heat sinking.

- Check for oscillations: Use an oscilloscope to monitor the output voltage and control signals for any signs of oscillation or instability. Adjust the compensation network or layout if necessary.

Frequently Asked Questions (FAQ)

-

Q: What is the purpose of a 24v to 12v converter?

A: A 24v to 12v converter is used to step down a 24-volt power supply to a 12-volt level, which is suitable for powering devices that require a 12-volt input. This conversion is necessary when the available power source has a higher voltage than the device being powered. -

Q: What are the main types of voltage converters?

A: The main types of voltage converters are linear voltage converters, switching voltage converters, boost converters, buck converters, and flyback converters. Each type has its own characteristics, advantages, and applications. -

Q: What are the advantages of using a switching converter over a linear regulator for a 24v to 12v converter?

A: Switching converters offer several advantages over linear regulators, including higher efficiency (80% to 95%), compact size due to smaller heat sinks, and higher current capacity. However, switching converters are more complex, may generate electromagnetic interference (EMI), and are generally more expensive than linear regulators. -

Q: What are the key components to consider when designing a 24v to 12v converter?

A: The key components to consider when designing a 24v to 12v converter include the voltage regulator or controller IC, switches (MOSFETs or diodes), inductors, and capacitors. Each component should be selected based on factors such as voltage and current ratings, efficiency, and compatibility with the chosen converter topology. -

Q: What are some important PCB layout considerations for a 24v to 12v converter?

A: Important PCB layout considerations for a 24v to 12v converter include minimizing loop areas to reduce stray inductance and EMI, using wide traces for high-current paths, providing adequate grounding, separating sensitive signals from high-current and high-frequency paths, using proper decoupling, and considering thermal management for heat-generating components.

Conclusion

Designing a 24v to 12v converter requires careful consideration of the converter topology, component selection, PCB layout, and testing procedures. Linear regulator-based converters are simple and inexpensive but have limitations in efficiency and current capacity. Switching converter-based designs, such as buck converters, offer higher efficiency and current handling but are more complex and may generate EMI.

When selecting components for a 24v to 12v converter, it’s essential to choose a suitable voltage regulator or controller IC, switches, inductors, and capacitors based on factors such as voltage and current ratings, efficiency, and compatibility with the chosen topology.

Proper PCB layout is crucial for the performance and reliability of the converter, with key considerations including minimizing loop areas, using wide traces, providing adequate grounding, separating sensitive signals, using proper decoupling, and addressing thermal management.

Testing and troubleshooting the converter involves visual inspection, continuity tests, power-on tests, load tests, efficiency measurements, and monitoring for issues such as overheating or oscillations.

By understanding the principles, design considerations, and best practices for 24v to 12v converters, engineers and hobbyists can effectively develop efficient and reliable power conversion solutions for a wide range of applications.

No responses yet