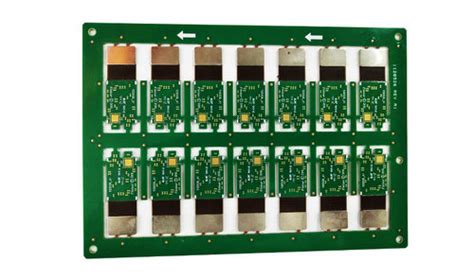

What is a PCB Stiffener?

A PCB stiffener is a mechanical support structure that is attached to a printed circuit board (PCB) to provide additional rigidity and stability. It is commonly used in flexible and rigid-flex PCBs to prevent bending, twisting, or other forms of mechanical stress that could damage the circuit board or its components.

PCB stiffeners are typically made from materials such as aluminum, stainless steel, or fiberglass-reinforced epoxy laminate (FR-4). They are designed to match the shape and size of the PCB and are attached using adhesives, screws, or other fastening methods.

Why Use a PCB Stiffener?

There are several reasons why a PCB stiffener might be necessary for a particular application:

-

Mechanical Support: The primary purpose of a PCB stiffener is to provide mechanical support to the circuit board. This is especially important for flexible and rigid-flex PCBs, which are designed to bend and flex in certain areas. Without a stiffener, these PCBs may be subjected to excessive stress, which can cause damage to the copper traces, solder joints, or components.

-

Vibration and Shock Resistance: In applications where the PCB is exposed to vibration or shock, a stiffener can help to absorb and dissipate the mechanical energy, reducing the risk of damage to the circuit board and its components.

-

Thermal Management: PCB stiffeners can also serve as heat sinks, helping to dissipate heat generated by components on the circuit board. This can be particularly useful in high-power applications or in situations where the PCB is exposed to high ambient temperatures.

-

Electromagnetic Interference (EMI) Shielding: In some cases, a metal PCB stiffener can be used as an EMI shield, helping to reduce the amount of electromagnetic interference that the circuit board emits or is exposed to.

Types of PCB Stiffeners

There are several types of PCB stiffeners available, each with its own advantages and disadvantages:

Aluminum Stiffeners

Aluminum is a popular choice for PCB stiffeners due to its low cost, lightweight, and good thermal conductivity. It is easy to machine and can be anodized for improved corrosion resistance. However, aluminum has a relatively high coefficient of thermal expansion (CTE), which can cause stress on the PCB if not properly designed.

Stainless Steel Stiffeners

Stainless steel offers excellent mechanical strength and durability, making it suitable for applications with high levels of stress or vibration. It also has a lower CTE than aluminum, reducing the risk of thermal stress on the PCB. However, stainless steel is more expensive and heavier than aluminum.

FR-4 Stiffeners

FR-4 is a glass-reinforced epoxy laminate material commonly used in PCB fabrication. FR-4 stiffeners offer several advantages, including a CTE that closely matches that of the PCB, good electrical insulation properties, and lower cost compared to metal stiffeners. However, FR-4 has lower thermal conductivity than metal stiffeners and may not be suitable for high-power applications.

Designing with PCB Stiffeners

When designing a PCB with a stiffener, several factors must be considered to ensure optimal performance and reliability:

-

Material Selection: The choice of stiffener material should be based on the specific requirements of the application, such as mechanical strength, thermal conductivity, CTE, and cost.

-

Stiffener Thickness: The thickness of the stiffener must be carefully selected to provide adequate mechanical support without adding unnecessary weight or bulk to the assembly. Typical stiffener thicknesses range from 0.5 mm to 3 mm.

-

Attachment Method: The method used to attach the stiffener to the PCB can impact the overall performance and reliability of the assembly. Common attachment methods include adhesives, screws, and rivets. The choice of attachment method should consider factors such as the size and shape of the PCB, the expected level of mechanical stress, and the operating environment.

-

Thermal Management: If the stiffener is being used as a heat sink, thermal simulations should be performed to ensure that it provides adequate cooling for the components on the PCB. The design of the stiffener should also consider the placement of thermal vias and other features to improve heat dissipation.

-

Grounding and Shielding: If the stiffener is being used for EMI shielding, it must be properly grounded to the PCB to be effective. The design of the stiffener should also consider the placement of grounding points and the use of conductive gaskets or other materials to ensure a good electrical connection between the stiffener and the PCB.

PCB Stiffener Materials Comparison

| Material | Advantages | Disadvantages |

|---|---|---|

| Aluminum | – Low cost – Lightweight – Good thermal conductivity – Easy to machine |

– High CTE compared to PCB – May require additional insulation |

| Stainless Steel | – Excellent mechanical strength – Good thermal conductivity – Low CTE compared to aluminum |

– Higher cost than aluminum – Heavier than aluminum |

| FR-4 | – CTE closely matches PCB – Good electrical insulation – Lower cost than metal stiffeners |

– Lower thermal conductivity than metal – May not be suitable for high-power applications |

PCB Stiffener Attachment Methods

| Method | Advantages | Disadvantages |

|---|---|---|

| Adhesives | – Simple and low-cost – No additional drilling required – Good for small and thin PCBs |

– Limited mechanical strength – May degrade over time or at high temperatures |

| Screws | – Excellent mechanical strength – Allows for disassembly and rework – Suitable for large and heavy PCBs |

– Requires drilling and tapping – May increase assembly time and cost |

| Rivets | – Good mechanical strength – Lower cost than screws – Faster assembly than screws |

– Requires drilling – Permanent attachment (no disassembly) |

FAQ

-

Q: Can a PCB stiffener be used with any type of PCB?

A: PCB stiffeners are primarily used with flexible and rigid-flex PCBs, which require additional mechanical support. They can also be used with rigid PCBs in applications that demand extra mechanical strength or thermal management. -

Q: How do I choose the right thickness for my PCB stiffener?

A: The thickness of the PCB stiffener depends on the specific requirements of your application. Factors to consider include the size and weight of the PCB, the expected level of mechanical stress, and the desired thermal performance. Typical stiffener thicknesses range from 0.5 mm to 3 mm. -

Q: Can I use a PCB stiffener for EMI shielding?

A: Yes, a metal PCB stiffener (such as aluminum or stainless steel) can be used for EMI shielding. To be effective, the stiffener must be properly grounded to the PCB and designed with features such as conductive gaskets to ensure a good electrical connection. -

Q: What adhesives are commonly used to attach PCB stiffeners?

A: Common adhesives for attaching PCB stiffeners include epoxy, acrylic, and silicone-based adhesives. The choice of adhesive depends on factors such as the materials being bonded, the operating temperature range, and the required mechanical strength. -

Q: Can I design my own custom PCB stiffener?

A: Yes, PCB stiffeners can be custom-designed to match the specific shape and size of your PCB. This allows for optimal mechanical support and thermal management. Many PCB fabrication and assembly services offer custom stiffener design and manufacturing as part of their offerings.

Conclusion

PCB stiffeners are essential components in many electronic assemblies, providing mechanical support, thermal management, and EMI shielding for flexible and rigid-flex PCBs. By understanding the different types of stiffeners available and the key design considerations, engineers can create robust and reliable PCB assemblies that can withstand the demands of various applications.

When selecting a PCB stiffener, it is important to consider factors such as material properties, thickness, attachment method, and thermal performance. By working closely with PCB fabrication and assembly partners, designers can ensure that their PCB stiffeners are optimized for their specific requirements, resulting in improved product performance and reliability.

No responses yet