What is Electroless Cu Deposition?

Electroless Cu deposition is a method of depositing copper onto a substrate through a chemical reduction reaction. Unlike electroplating, which requires an external electrical current, electroless Cu deposition relies on the presence of a reducing agent in the plating solution. The reducing agent, typically formaldehyde or borohydride, donates electrons to the copper ions (Cu2+) in the solution, reducing them to metallic copper (Cu0). The deposited copper layer adheres to the substrate surface, forming a uniform and continuous coating.

The overall reaction for electroless Cu deposition can be represented as follows:

Cu2+ + 2HCHO + 4OH- -> Cu0 + 2HCOO- + 2H2O + H2

In this reaction, formaldehyde (HCHO) acts as the reducing agent, and hydroxide ions (OH-) provide the necessary alkalinity for the reaction to proceed.

Advantages of Electroless Cu Deposition

Electroless Cu deposition offers several advantages over traditional electroplating methods:

-

Uniform coating: Electroless Cu deposition produces a uniform and conformal coating on complex geometries and intricate surfaces. This is because the deposition process is not limited by the “throwing power” of an electrical current, as in electroplating.

-

No external power source: The absence of an external power source simplifies the setup and reduces the cost of the deposition process. This makes electroless Cu deposition suitable for applications where electrical conductivity is not available or desired.

-

Selective deposition: By properly designing the substrate surface and the plating solution, electroless Cu can be selectively deposited on specific areas of the substrate. This allows for the creation of patterned copper layers without the need for additional masking steps.

-

Excellent adhesion: Electroless Cu deposits exhibit strong adhesion to various substrates, including metals, polymers, and ceramics. This is due to the chemical interaction between the substrate surface and the deposited copper layer.

Applications of Electroless Cu Deposition

Electroless Cu deposition finds applications in various fields, such as:

-

Printed circuit boards (PCBs): Electroless Cu is used as a seed layer for the subsequent electroplating of copper in the manufacturing of PCBs. It ensures uniform coverage and good adhesion of the copper layer to the dielectric substrate.

-

ElectronIC Packaging: Electroless Cu is employed in the fabrication of interconnects and metallization layers in electronic packaging, such as flip-chip bonding and 3D integration.

-

Electromagnetic interference (EMI) shielding: Electroless Cu coatings are used to provide EMI shielding for electronic devices, protecting them from external electromagnetic interference and preventing the emission of unwanted signals.

-

Decorative coatings: Electroless Cu can be used as a base layer for subsequent plating of other metals, such as nickel and chromium, to achieve decorative and protective finishes on various objects.

-

Catalysis: Electroless Cu deposits can serve as catalytic surfaces for chemical reactions, such as the electroless deposition of other metals or the synthesis of organic compounds.

Factors Affecting Electroless Cu Deposition

Several factors influence the quality and properties of electroless Cu deposits:

-

Plating solution composition: The composition of the electroless Cu plating solution plays a crucial role in determining the deposition rate, morphology, and properties of the deposited copper layer. The solution typically contains a copper salt (e.g., copper sulfate), a reducing agent (e.g., formaldehyde), a complexing agent (e.g., EDTA), and a pH regulator (e.g., sodium hydroxide).

-

Substrate surface preparation: Proper surface preparation of the substrate is essential for achieving good adhesion and uniformity of the electroless Cu deposit. This may involve cleaning, etching, and activation steps to remove contaminants and create a suitable surface for deposition.

-

Temperature: The deposition rate and morphology of electroless Cu are influenced by the temperature of the plating solution. Higher temperatures generally lead to faster deposition rates and smoother deposits, but excessive temperatures can cause solution instability and the formation of nodules or precipitates.

-

pH: The pH of the electroless Cu plating solution affects the stability of the solution and the deposition rate. Typically, alkaline conditions (pH 10-14) are required for the reduction of copper ions and the suppression of hydrogen evolution.

-

Agitation: Adequate agitation of the plating solution is necessary to ensure a uniform supply of reactants to the substrate surface and to prevent the formation of local concentration gradients. This can be achieved through mechanical stirring, air sparging, or ultrasonic agitation.

Challenges and Future Developments

Despite its numerous advantages, electroless Cu deposition faces several challenges:

-

Bath stability: Electroless Cu plating solutions are inherently unstable due to the presence of a reducing agent. The solution can spontaneously decompose, leading to the formation of copper precipitates and the depletion of the reducing agent. Careful control of the solution composition and operating conditions is necessary to maintain bath stability.

-

Substrate compatibility: Some substrates, particularly those with low surface energy or high chemical inertness, may require special pretreatment steps to enable the deposition of electroless Cu. Developing suitable surface modification techniques and adhesion promoters is an ongoing research area.

-

Environmental concerns: The use of formaldehyde as a reducing agent in electroless Cu plating raises environmental and health concerns due to its toxicity and potential carcinogenicity. Efforts are being made to develop alternative reducing agents that are more environmentally friendly and safer to handle.

Future developments in electroless Cu deposition are focused on addressing these challenges and expanding the application scope of the technology. Some key areas of research include:

-

Novel reducing agents: The development of new reducing agents, such as amino acids, hypophosphites, and hydrazine derivatives, aims to replace formaldehyde and improve the environmental sustainability of electroless Cu plating.

-

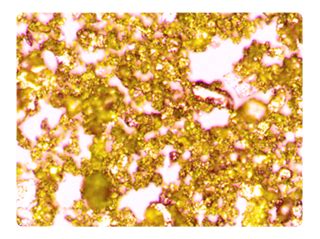

Nanostructured deposits: By controlling the deposition conditions and incorporating additives, electroless Cu can be engineered to produce nanostructured deposits with enhanced properties, such as high surface area, improved catalytic activity, and unique optical or magnetic properties.

-

Composite coatings: The co-deposition of copper with other materials, such as polymers, ceramics, or graphene, can lead to the formation of composite coatings with tailored properties for specific applications.

-

Additive manufacturing: Electroless Cu deposition can be integrated with additive manufacturing techniques, such as 3D printing, to create complex metal-polymer hybrid structures with embedded conductive pathways.

Conclusion

Electroless Cu deposition is a versatile and efficient method for producing uniform and adherent copper coatings on various substrates. Its advantages, such as the ability to coat non-conductive surfaces and the absence of an external power source, make it attractive for numerous applications in electronics, catalysis, and decorative coatings. However, challenges related to bath stability, substrate compatibility, and environmental concerns need to be addressed to further advance the technology. Ongoing research efforts in developing new reducing agents, nanostructured deposits, composite coatings, and integrating electroless Cu with additive manufacturing techniques hold promise for expanding the application scope and sustainability of this important deposition method.

Frequently Asked Questions (FAQ)

-

What is the difference between electroless Cu deposition and electroplating?

Electroless Cu deposition relies on a chemical reduction reaction to deposit copper onto a substrate without the need for an external electrical current. In contrast, electroplating requires an external power source to drive the deposition of copper through the reduction of copper ions at the cathode. -

Can electroless Cu be deposited on non-conductive substrates?

Yes, one of the main advantages of electroless Cu deposition is its ability to coat non-conductive substrates, such as polymers and ceramics. This is because the deposition process is not dependent on the electrical conductivity of the substrate. -

What are the main components of an electroless Cu plating solution?

A typical electroless Cu plating solution consists of a copper salt (e.g., copper sulfate) as the source of copper ions, a reducing agent (e.g., formaldehyde) to reduce the copper ions to metallic copper, a complexing agent (e.g., EDTA) to stabilize the copper ions in solution, and a pH regulator (e.g., sodium hydroxide) to maintain the necessary alkaline conditions. -

How does surface preparation affect the quality of electroless Cu deposits?

Proper surface preparation is crucial for achieving good adhesion and uniformity of electroless Cu deposits. The substrate surface must be cleaned to remove contaminants, and in some cases, etched or activated to create a suitable surface for deposition. Inadequate surface preparation can lead to poor adhesion, non-uniformity, or the formation of defects in the deposited copper layer. -

What are some of the environmental concerns associated with electroless Cu deposition?

The use of formaldehyde as a reducing agent in electroless Cu plating raises environmental and health concerns due to its toxicity and potential carcinogenicity. Efforts are being made to develop alternative reducing agents that are more environmentally friendly and safer to handle, such as amino acids, hypophosphites, and hydrazine derivatives.

| Property | Electroless Cu Deposition | Electroplating |

|---|---|---|

| Deposition mechanism | Chemical reduction | Electrical reduction |

| External power source | Not required | Required |

| Substrate conductivity | Can coat non-conductive substrates | Requires conductive substrates |

| Throwing power | Uniform coverage on complex geometries | Limited by current distribution |

| Adhesion | Excellent adhesion due to chemical interaction | Adhesion depends on surface preparation |

| Selective deposition | Possible with proper surface design | Requires masking or selective plating techniques |

Table 1: Comparison of electroless Cu deposition and electroplating.

| Component | Function |

|---|---|

| Copper salt | Source of copper ions (Cu2+) |

| Reducing agent | Reduces copper ions to metallic copper (Cu0) |

| Complexing agent | Stabilizes copper ions in solution |

| pH regulator | Maintains alkaline conditions necessary for deposition |

Table 2: Main components of an electroless Cu plating solution and their functions.

No responses yet