What is Profiling V-cut Scoring?

Profiling V-cut scoring, also known as V-grooving or V-notching, is a technique used in various industries to create precise, V-shaped grooves or cuts on the surface of materials. This process is essential for applications that require easy folding, bending, or separating of materials, such as in packaging, printing, or construction.

The V-cut is made by using specialized tools or machines that remove material at a specific angle, creating a V-shaped groove. The depth and angle of the cut can be adjusted depending on the material and the desired outcome.

Applications of Profiling V-cut Scoring

Profiling V-cut scoring has a wide range of applications across different industries. Some of the most common applications include:

Packaging Industry

In the packaging industry, V-cut scoring is used to create boxes, folders, and other containers that require easy folding and assembly. The V-shaped grooves allow for precise and clean folds, ensuring that the final product looks professional and is structurally sound.

Printing Industry

V-cut scoring is also used in the printing industry to create folded brochures, greeting cards, and other printed materials. The technique allows for easy folding without damaging the printed content or images.

Construction Industry

In the construction industry, V-cut scoring is used to create clean, straight lines on drywall, cement board, or other building materials. This technique is particularly useful for creating precise corners or joints.

Advantages of Profiling V-cut Scoring

Profiling V-cut scoring offers several advantages over other cutting or grooving methods:

-

Precision: V-cut scoring allows for high precision cuts, ensuring that the final product is accurate and consistent.

-

Clean edges: The V-shaped groove created by V-cut scoring results in clean, smooth edges without any tear-out or splintering.

-

Easy folding: Materials with V-cut grooves are easier to fold along the scored line, as the groove acts as a guide and reduces the risk of cracking or breaking.

-

Versatility: V-cut scoring can be used on a wide range of materials, including paper, cardboard, plastic, wood, and metal.

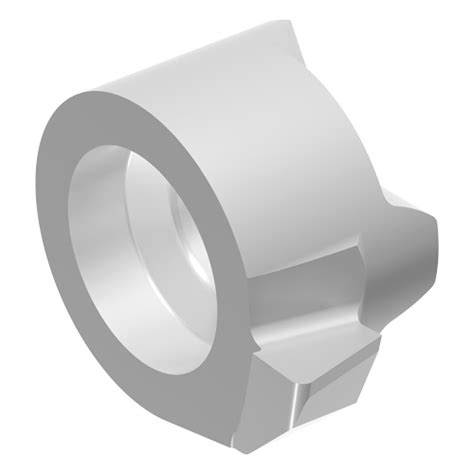

Tools and Machines for Profiling V-cut Scoring

There are various tools and machines available for creating V-cut grooves, depending on the material and the scale of the project. Some common tools include:

Manual V-Groovers

Manual V-groovers are hand-held tools that consist of a V-shaped blade attached to a handle. These tools are suitable for small-scale projects or for creating V-grooves on softer materials like foam board or cardboard.

Table Saws with V-Grooving Blades

Table saws can be fitted with specialized V-grooving blades to create V-cut grooves on wood or other materials. These blades have a V-shaped profile that cuts the material at the desired angle.

CNC Machines

Computer Numerical Control (CNC) machines can be programmed to create V-cut grooves on various materials with high precision and speed. These machines are ideal for large-scale production or complex designs.

Techniques for Profiling V-cut Scoring

To achieve the best results with profiling V-cut scoring, consider the following techniques:

-

Choose the right tool: Select the appropriate tool or machine based on the material, the desired depth and angle of the cut, and the scale of the project.

-

Set the correct depth: Adjust the depth of the V-groove according to the material thickness and the desired folding or bending properties. A deeper groove will make folding easier but may weaken the material.

-

Align the tool properly: Ensure that the V-grooving tool or blade is aligned correctly with the material to create a straight and consistent groove.

-

Use a guide or template: For precision and repeatability, use a guide or template to ensure that the V-grooves are positioned accurately on the material.

-

Practice on scrap material: Before working on the final product, practice V-cut scoring on scrap material to get a feel for the tool and the technique.

Common Materials for Profiling V-cut Scoring

Profiling V-cut scoring can be used on a variety of materials, each with its own characteristics and requirements. Some common materials include:

Paper and Cardboard

Paper and cardboard are among the most common materials for V-cut scoring, particularly in the packaging and printing industries. The depth and angle of the V-groove will depend on the thickness and type of paper or cardboard being used.

Plastic

V-cut scoring can be used on various types of plastic, such as PVC, acrylic, or polypropylene. The technique is often used to create hinges or fold lines in plastIC Packaging or displays.

Wood

V-cut scoring is used in woodworking to create decorative grooves or to make clean, precise cuts for joints or corners. The type of wood and its grain direction will influence the depth and angle of the V-groove.

Metal

V-cut scoring can be used on thin metal sheets, such as aluminum or brass, to create fold lines or decorative patterns. The technique requires specialized tools and proper safety precautions due to the hardness of the material.

Factors Affecting Profiling V-cut Scoring

Several factors can affect the quality and effectiveness of profiling V-cut scoring:

-

Material thickness: The thickness of the material will determine the depth and angle of the V-groove required for optimal folding or bending.

-

Grain direction: When working with wood or other materials with a distinct grain, the direction of the grain can affect the ease and cleanness of the V-cut.

-

Tool sharpness: A sharp V-grooving tool or blade will produce cleaner, more precise cuts and minimize tear-out or splintering.

-

Cutting speed: The speed at which the V-cut is made can affect the quality of the groove. Slower speeds may be necessary for harder materials or thicker stock.

-

Clamping: Proper clamping of the material during V-cut scoring ensures that the workpiece remains stable and the resulting groove is straight and consistent.

Safety Considerations for Profiling V-cut Scoring

When performing profiling V-cut scoring, it is essential to follow proper safety guidelines to prevent accidents and injuries:

-

Wear protective gear: Always wear safety glasses, hearing protection, and dust masks when operating V-grooving tools or machines.

-

Keep tools sharp: Maintain the sharpness of V-grooving blades or tools to ensure clean cuts and reduce the risk of kickback or binding.

-

Use proper clamping: Securely clamp the workpiece to prevent shifting or movement during the cutting process.

-

Follow manufacturer guidelines: Adhere to the manufacturer’s instructions and recommendations for the specific V-grooving tool or machine being used.

-

Keep work area clean: Maintain a clean and organized work area to minimize the risk of tripping, slipping, or other accidents.

Troubleshooting Common Issues with Profiling V-cut Scoring

Despite careful technique and proper tool selection, issues may arise during profiling V-cut scoring. Some common problems and their solutions include:

-

Tear-out or splintering: If the V-groove edges are rough or splintered, try using a sharper blade, reducing the cutting speed, or adjusting the angle of the cut.

-

Inconsistent groove depth: Inconsistent groove depth can be caused by a dull blade, improper clamping, or uneven pressure during the cut. Ensure that the blade is sharp, the workpiece is securely clamped, and the tool is applied with consistent pressure.

-

Crooked or wavy grooves: Crooked or wavy grooves can result from poor alignment, uneven pressure, or a dull blade. Use a guide or template to ensure straight cuts, maintain consistent pressure, and keep the blade sharp.

-

Material cracking or breaking: If the material cracks or breaks during folding, the V-groove may be too deep or the angle too steep. Adjust the depth and angle of the cut to suit the material thickness and properties.

Frequently Asked Questions (FAQ)

- What is the difference between V-cut scoring and other grooving methods?

V-cut scoring creates a V-shaped groove in the material, which allows for easy folding and clean, precise edges. Other grooving methods, such as U-grooving or square grooving, create different shaped grooves and may not provide the same folding or bending properties.

- Can V-cut scoring be used on any material?

While V-cut scoring can be used on a wide range of materials, including paper, cardboard, plastic, wood, and metal, the specific technique and tools required may vary depending on the material. Some materials may be more challenging to work with or require specialized equipment.

- How do I determine the correct depth and angle for a V-cut groove?

The depth and angle of the V-cut groove will depend on the material being used, its thickness, and the desired folding or bending properties. Generally, a deeper groove will make folding easier but may weaken the material. It’s best to consult the manufacturer’s guidelines or perform tests on scrap material to determine the optimal depth and angle.

- Can V-cut scoring be done by hand, or is a machine required?

V-cut scoring can be done by hand using manual tools like V-groovers for small-scale projects or softer materials. However, for larger projects, harder materials, or higher precision, machines like table saws with V-grooving blades or CNC machines are recommended.

- How can I ensure consistent and accurate V-cut grooves?

To ensure consistent and accurate V-cut grooves, use a guide or template to maintain proper alignment, clamp the workpiece securely, and apply consistent pressure during the cutting process. Additionally, keep the V-grooving tools or blades sharp and clean to minimize tear-out or splintering.

Conclusion

Profiling V-cut scoring is an essential technique for creating precise, V-shaped grooves in various materials, allowing for easy folding, bending, or separating. With applications in packaging, printing, construction, and more, V-cut scoring offers precision, clean edges, and versatility.

By understanding the tools, techniques, and factors affecting V-cut scoring, professionals can achieve optimal results and create high-quality products. Following safety guidelines and troubleshooting common issues will help ensure a successful V-cut scoring process.

As technology advances, new tools and techniques for V-cut scoring may emerge, further improving the efficiency and precision of this valuable grooving method.

| Material | Common Applications | Recommended Tools |

|---|---|---|

| Paper/Cardboard | Packaging, printing | Manual V-groovers, table saws with V-grooving blades |

| Plastic | Packaging, displays | CNC machines, table saws with V-grooving blades |

| Wood | Decorative grooves, joints | Table saws with V-grooving blades, CNC machines |

| Metal | Fold lines, decorative patterns | Specialized V-grooving tools, CNC machines |

This table provides a quick overview of common materials used in profiling V-cut scoring, their typical applications, and the recommended tools for each material.

No responses yet