Introduction to Radar Technology and PCBs

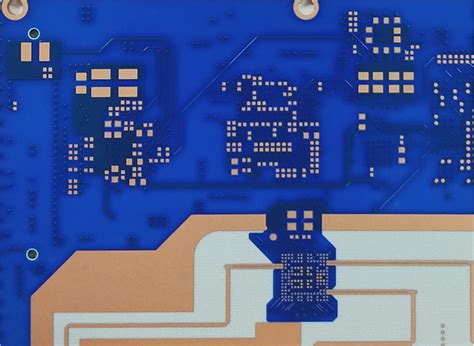

Radar, which stands for Radio Detection and Ranging, is a technology that uses radio waves to determine the distance, angle, and velocity of objects. It has a wide range of applications, from military and aviation to weather forecasting and autonomous vehicles. At the heart of every radar system is a complex electronic circuit that generates, transmits, and receives radio frequency (RF) signals. This circuit is typically implemented on a printed circuit board (PCB), known as a Radar PCB.

In this article, we will dive deep into the world of radar PCBs, exploring their design, fabrication, and applications. We will discuss the key components of a radar PCB, the challenges in designing and manufacturing them, and the latest advancements in radar technology. Whether you are an electronics engineer, a hobbyist, or simply curious about how radar works, this article will provide you with a comprehensive overview of this fascinating field.

What is a PCB?

Before we delve into the specifics of radar PCBs, let’s briefly review what a PCB is and how it works. A PCB is a flat board made of insulating materials, such as fiberglass or plastic, with conductive tracks, pads, and other features etched from copper sheets laminated onto the board. These copper traces interconnect various electronic components, such as resistors, capacitors, and integrated circuits (ICs), to create a complete electronic circuit.

PCBs offer several advantages over traditional point-to-point wiring:

- Compact size: PCBs allow for the miniaturization of electronic circuits, making them ideal for space-constrained applications.

- Reliability: The solid construction of PCBs reduces the risk of loose connections and short circuits, improving the overall reliability of the circuit.

- Mass production: PCBs can be easily mass-produced using automated manufacturing processes, reducing the cost and time required to produce large quantities of electronic devices.

- Consistency: PCBs ensure that each circuit is identical, eliminating variations that may occur with manual wiring.

Key Components of a Radar PCB

A radar PCB consists of several key components that work together to generate, transmit, and receive RF signals. Let’s take a closer look at each of these components:

Antenna

The antenna is perhaps the most critical component of a radar system, as it is responsible for transmitting and receiving RF signals. There are several types of antennas used in radar applications, including:

- Parabolic reflector antennas: These antennas use a parabolic reflector to focus the transmitted signal into a narrow beam, increasing the range and resolution of the radar.

- Phased array antennas: These antennas consist of multiple radiating elements that can be individually controlled to steer the radar beam electronically, without physically moving the antenna.

- Slotted waveguide antennas: These antennas are formed by cutting slots into a waveguide, allowing the RF energy to radiate out of the slots.

The choice of antenna depends on the specific requirements of the radar application, such as the desired range, resolution, and scanning speed.

Transmitter

The transmitter generates the RF signal that is sent out by the antenna. It typically consists of an oscillator that generates a high-frequency signal, which is then amplified by a power amplifier to increase its strength. The transmitter may also include a modulator that encodes information onto the RF signal, such as the pulse width or frequency, to improve the radar’s performance.

Receiver

The receiver picks up the RF signals reflected back from the target and processes them to extract information about the target’s distance, speed, and direction. It typically consists of a low-noise amplifier (LNA) that amplifies the weak reflected signals, followed by a mixer that downconverts the RF signal to a lower frequency for easier processing. The receiver may also include filters and demodulators to remove noise and extract the desired information from the signal.

Signal Processing Unit

The signal processing unit is responsible for analyzing the received signals and extracting useful information from them. It typically consists of an analog-to-digital converter (ADC) that converts the analog received signals into digital data, followed by digital signal processors (DSPs) or field-programmable gate arrays (FPGAs) that perform complex algorithms on the data to determine the target’s parameters.

Power Supply

The power supply provides the necessary voltage and current to all the components on the radar PCB. It typically includes voltage regulators, transformers, and rectifiers to convert the input power (e.g., from a battery or AC mains) into the required DC voltages for the various components.

Designing a Radar PCB

Designing a radar PCB requires careful consideration of several factors, such as the operating frequency, power requirements, and signal integrity. Let’s explore some of the key design considerations:

Material Selection

The choice of PCB material is critical in radar applications, as it affects the board’s dielectric constant, loss tangent, and thermal conductivity. The most common materials used for radar PCBs are:

- FR-4: A low-cost, general-purpose material that is suitable for low-frequency applications up to a few GHz.

- Rogers: A high-performance material with low dielectric loss and stable dielectric constant, making it suitable for high-frequency applications up to tens of GHz.

- Teflon: A low-loss material with excellent thermal stability, making it suitable for high-power applications.

The following table compares the properties of these materials:

| Material | Dielectric Constant | Loss Tangent | Thermal Conductivity (W/mK) |

|---|---|---|---|

| FR-4 | 4.3 – 4.7 | 0.02 – 0.03 | 0.3 – 0.4 |

| Rogers | 2.2 – 10.2 | 0.0009 – 0.003 | 0.6 – 1.0 |

| Teflon | 2.0 – 2.1 | 0.0001 – 0.0002 | 0.2 – 0.3 |

Impedance Matching

Impedance matching is crucial in radar PCBs to ensure maximum power transfer and minimize signal reflections. The characteristic impedance of the transmission lines on the PCB must match the impedance of the components connected to them, typically 50 ohms. This can be achieved by carefully selecting the width and spacing of the copper traces based on the PCB material and thickness.

Grounding and Shielding

Proper grounding and shielding are essential in radar PCBs to minimize electromagnetic interference (EMI) and crosstalk between different sections of the circuit. This can be achieved by using ground planes, via stitching, and shielding cans around sensitive components. It is also important to separate the digital and analog sections of the circuit to prevent noise coupling.

Thermal Management

Radar PCBs often dissipate significant amounts of power, particularly in the transmitter section. Proper thermal management is essential to prevent overheating and ensure reliable operation. This can be achieved by using heatsinks, thermal vias, and fans to dissipate heat away from the components. The PCB material and layout should also be chosen to minimize thermal resistance and promote even heat distribution.

Manufacturing a Radar PCB

Once the design of the radar PCB is complete, it needs to be manufactured using specialized equipment and processes. The manufacturing process typically involves the following steps:

-

PCB fabrication: The PCB is fabricated by laminating copper foils onto the substrate material, followed by etching away the unwanted copper to form the desired circuit pattern. This process is repeated for each layer of the PCB, which are then laminated together to form the final board.

-

Component placement: The electronic components are placed onto the PCB using automated pick-and-place machines. The components are typically packaged in surface-mount device (SMD) packages to minimize their size and improve their performance at high frequencies.

-

Soldering: The components are soldered onto the PCB using reflow or wave soldering processes. Reflow soldering is typically used for SMD components, while wave soldering is used for through-hole components.

-

Inspection and testing: The manufactured PCB is inspected visually and electrically to ensure that it meets the design specifications. This may involve using automated optical inspection (AOI) machines, X-ray machines, and electrical testing equipment.

Applications of Radar PCBs

Radar PCBs find applications in a wide range of fields, from military and aerospace to automotive and consumer electronics. Here are some of the most common applications:

Military and Aerospace

Radar is extensively used in military and aerospace applications for surveillance, tracking, and guidance. Some examples include:

- Air traffic control: Radar is used to monitor and control the movement of aircraft in the airspace, ensuring safe and efficient operations.

- Missile guidance: Radar is used to guide missiles towards their targets by providing real-time information about the target’s location and velocity.

- Weather monitoring: Radar is used to monitor weather patterns and track the movement of storms and hurricanes.

Automotive

Radar is increasingly being used in automotive applications for advanced driver assistance systems (ADAS) and autonomous driving. Some examples include:

- Adaptive cruise control: Radar is used to maintain a safe distance from the vehicle in front by automatically adjusting the speed of the vehicle.

- Blind spot detection: Radar is used to detect vehicles in the blind spot of the car and alert the driver.

- Autonomous emergency braking: Radar is used to detect obstacles in front of the vehicle and automatically apply the brakes to avoid a collision.

Industrial and Scientific

Radar PCBs are also used in various industrial and scientific applications, such as:

- Level measurement: Radar is used to measure the level of liquids and solids in tanks and silos, providing accurate and reliable measurements.

- Speed measurement: Radar is used to measure the speed of moving objects, such as vehicles and conveyor belts.

- Geophysical exploration: Radar is used to map the subsurface of the earth, detecting underground objects and structures.

Advancements in Radar Technology

Radar technology is constantly evolving, with new advancements being made in areas such as materials, components, and signal processing. Here are some of the latest trends and developments in radar PCBs:

Millimeter-Wave Radar

Millimeter-wave (mmWave) radar operates at frequencies between 30 and 300 GHz, offering higher resolution and smaller antenna size compared to traditional radar. This makes mmWave radar ideal for applications such as autonomous vehicles and drones, where space is limited, and high precision is required. However, designing and manufacturing mmWave radar PCBs is challenging due to the high frequencies involved and the need for specialized materials and components.

Cognitive Radar

Cognitive radar is an emerging technology that uses machine learning and adaptive signal processing to improve the performance and flexibility of radar systems. Cognitive radar can dynamically adjust its parameters based on the environment and the target’s behavior, optimizing its performance in real-time. This requires advanced signal processing algorithms and high-performance computing hardware, such as FPGAs and GPUs.

3D Radar

3D radar uses multiple antennas and advanced signal processing to provide three-dimensional information about the target’s location and shape. This is particularly useful in applications such as autonomous vehicles and robotics, where a detailed understanding of the environment is required. 3D radar PCBs require complex antenna arrays and high-speed digital interfaces to process the large amounts of data generated.

Frequently Asked Questions (FAQ)

What is the difference between radar and lidar?

Radar and lidar are both remote sensing technologies used for detecting and measuring objects, but they differ in the type of electromagnetic radiation they use. Radar uses radio waves, while lidar uses laser light. Lidar offers higher resolution and can create detailed 3D maps of the environment, but it is more expensive and has a shorter range compared to radar.

Can radar PCBs be used for detecting human motion?

Yes, radar PCBs can be used for detecting human motion in applications such as security systems, occupancy sensing, and fall detection. These applications typically use low-power, short-range radar operating in the 5-10 GHz frequency range. The radar can detect the tiny movements of the human body, such as breathing and heartbeat, by measuring the Doppler shift of the reflected signal.

How do I choose the right PCB material for my radar application?

The choice of PCB material depends on the operating frequency, power level, and environmental conditions of the radar application. For high-frequency applications (above 10 GHz), low-loss materials such as Rogers or Teflon are typically used. For high-power applications, materials with high thermal conductivity, such as aluminum or copper-backed PCBs, are preferred. For harsh environments, such as high humidity or temperature, materials with good stability and moisture resistance, such as polyimide or ceramic, are used.

What are the challenges in manufacturing radar PCBs?

Manufacturing radar PCBs requires specialized equipment and processes due to the high frequencies and tight tolerances involved. Some of the challenges include:

– Achieving tight control over the dielectric constant and thickness of the PCB material

– Maintaining high manufacturing precision and repeatability for the copper traces and vias

– Ensuring proper impedance matching and signal integrity throughout the PCB

– Minimizing the effects of manufacturing defects, such as copper roughness and delamination

– Implementing effective shielding and grounding techniques to minimize EMI and crosstalk

What is the future of radar technology?

The future of radar technology is exciting, with several emerging trends and applications on the horizon. Some of the key areas of development include:

– Integration of radar with other sensors, such as cameras and lidar, to create multi-modal sensing systems

– Development of more compact and low-cost radar modules for mass-market applications, such as smart homes and wearables

– Expansion of radar into new frequency bands, such as terahertz and sub-terahertz, for high-resolution imaging and sensing

– Application of machine learning and artificial intelligence techniques to improve the performance and adaptability of radar systems

– Integration of radar with 5G and IoT networks for enhanced connectivity and data fusion

As radar technology continues to evolve, we can expect to see more innovative and transformative applications in fields such as autonomous vehicles, robotics, healthcare, and beyond.

No responses yet