Types of PCBA Equipment

There are several types of PCBA equipment used in the manufacturing process. Here are some of the most common ones:

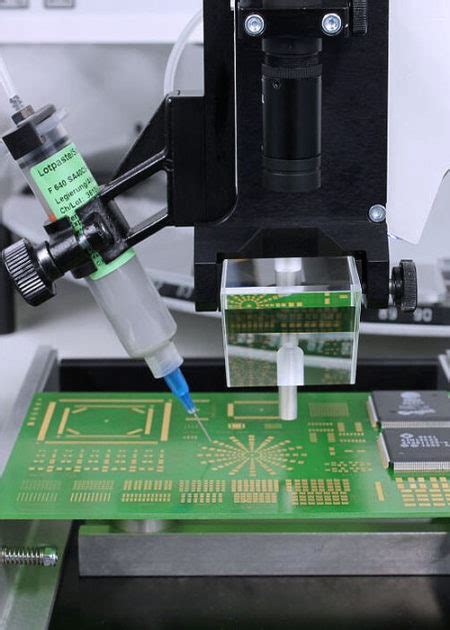

Solder Paste Printer

A solder paste printer is used to apply solder paste onto the PCB. It uses a stencil to ensure that the solder paste is applied accurately and consistently. The solder paste printer is an essential piece of equipment in the PCBA process as it helps to ensure that the components are properly soldered onto the PCB.

Pick and Place Machine

A pick and place machine is used to place electronic components onto the PCB. It uses a vacuum nozzle to pick up the components and place them accurately onto the PCB. The pick and place machine is a high-speed machine that can place thousands of components per hour, making it an essential piece of equipment in high-volume PCBA production.

Reflow Oven

A reflow oven is used to melt the solder paste and permanently attach the electronic components to the PCB. It uses a specific temperature profile to ensure that the solder paste melts and flows correctly, creating a strong and reliable solder joint. The reflow oven is an essential piece of equipment in the PCBA process as it helps to ensure the reliability and durability of the electronic circuit.

Automated Optical Inspection (AOI) Machine

An AOI machine is used to inspect the PCB for any defects or errors. It uses high-resolution cameras and advanced image processing algorithms to detect any issues such as missing components, incorrect component placement, or solder defects. The AOI machine is an essential piece of equipment in the PCBA process as it helps to ensure the quality and reliability of the electronic circuit.

In-Circuit Test (ICT) Machine

An ICT machine is used to test the functionality of the electronic circuit. It uses a bed of nails fixture to make contact with specific points on the PCB and test the circuit for any faults or issues. The ICT machine is an essential piece of equipment in the PCBA process as it helps to ensure that the electronic circuit is functioning correctly before it is shipped to the customer.

Factors to Consider When Choosing PCBA Equipment

When choosing PCBA equipment, there are several factors to consider to ensure that you get the right equipment for your needs. Here are some of the most important factors to consider:

Production Volume

The production volume is an essential factor to consider when choosing PCBA equipment. If you have a high-volume production, you will need equipment that can handle the high throughput, such as a high-speed pick and place machine or a large reflow oven. On the other hand, if you have a low-volume production, you may not need such high-end equipment and can opt for smaller and more affordable options.

Component Size and Type

The size and type of components used in your PCBA process will also impact your choice of equipment. If you are using small or delicate components, you will need a pick and place machine with a high level of precision and accuracy. Similarly, if you are using large or heavy components, you will need a machine that can handle the weight and size of the components.

Budget

Your budget is also an important factor to consider when choosing PCBA equipment. High-end equipment can be expensive, so you need to balance your needs with your budget. It’s important to invest in quality equipment that will meet your needs and provide reliable performance, but you also need to be mindful of your budget constraints.

Floor Space

The amount of floor space available in your facility is another important factor to consider when choosing PCBA equipment. Some equipment, such as large reflow ovens or automated assembly lines, can take up a significant amount of space. You need to ensure that you have sufficient space to accommodate the equipment and allow for easy movement and maintenance.

Maintenance and Support

Finally, you need to consider the maintenance and support requirements of the equipment. PCBA equipment requires regular maintenance to ensure optimal performance and longevity. You need to ensure that you have access to reliable maintenance and support services, either in-house or through the equipment vendor.

Common PCBA Equipment Manufacturers

There are several manufacturers of PCBA equipment, each with their own strengths and specialties. Here are some of the most common PCBA equipment manufacturers:

| Manufacturer | Specialty |

|---|---|

| Panasonic | Pick and place machines |

| Yamaha | Pick and place machines |

| Juki | Pick and place machines |

| Heller | Reflow ovens |

| BTU | Reflow ovens |

| Rehm | Reflow ovens |

| Koh Young | AOI machines |

| Saki | AOI machines |

| Omron | AOI machines |

| Teradyne | ICT machines |

| Keysight | ICT machines |

| Takaya | Flying probe testers |

Frequently Asked Questions (FAQ)

1. What is the difference between throughhole and surface mount technology?

Throughhole technology involves inserting component leads through holes drilled in the PCB and soldering them in place on the opposite side. Surface mount technology (SMT) involves placing components directly onto the surface of the PCB and soldering them in place. SMT is more common in modern PCBA due to its higher component density and faster assembly times.

2. What is the purpose of a stencil in solder paste printing?

A stencil is used to ensure that the solder paste is applied accurately and consistently onto the PCB. It is a thin metal sheet with holes cut out in the shape of the component pads. The stencil is placed over the PCB, and the solder paste is applied through the holes onto the pads.

3. What is the difference between a reflow oven and a wave soldering machine?

A reflow oven is used for surface mount components and involves applying solder paste to the PCB, placing the components, and then heating the entire board to melt the solder and attach the components. A wave soldering machine is used for throughhole components and involves passing the PCB over a wave of molten solder to attach the components.

4. What is the purpose of an AOI machine?

An automated optical inspection (AOI) machine is used to inspect the PCB for any defects or errors after the components have been placed and soldered. It uses high-resolution cameras and advanced image processing algorithms to detect any issues such as missing components, incorrect component placement, or solder defects.

5. How often should PCBA equipment be maintained?

The maintenance frequency of PCBA equipment depends on several factors, such as the type of equipment, the production volume, and the environment in which it is used. Generally, equipment should be maintained on a regular basis, such as every few months or after a certain number of production cycles. It’s important to follow the manufacturer’s recommended maintenance schedule to ensure optimal performance and longevity of the equipment.

Conclusion

PCBA equipment is essential for the manufacturing of electronic devices. There are several types of equipment used in the PCBA process, each with its own specific function and purpose. When choosing PCBA equipment, it’s important to consider factors such as production volume, component size and type, budget, floor space, and maintenance and support requirements. There are several common manufacturers of PCBA equipment, each with their own strengths and specialties. By understanding the different types of equipment and the factors to consider when choosing them, you can ensure that you have the right equipment for your PCBA needs.

No responses yet