Introduction to FR4 Quality

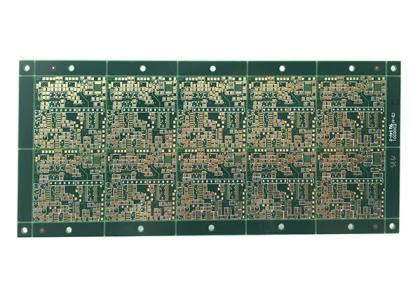

FR4 (Flame Retardant 4) is a widely used material in the production of printed circuit boards (PCBs). It is a composite material made from woven fiberglass cloth with an epoxy resin binder that is flame resistant. The quality of FR4 is crucial for the performance and reliability of electronic devices that utilize PCBs. In this article, we will explore the various aspects of FR4 quality and what to expect when selecting FR4 for your PCB manufacturing needs.

Factors Affecting FR4 Quality

Several factors can impact the quality of FR4 material. These include:

1. Raw Material Selection

The quality of the raw materials used in the production of FR4 plays a significant role in determining the final product’s quality. The fiberglass cloth and epoxy resin must meet specific standards to ensure the desired performance characteristics of the FR4 Laminate.

2. Manufacturing Process

The manufacturing process of FR4 involves several steps, including impregnation, layup, pressing, and curing. Each step must be carefully controlled to maintain consistent quality. Any deviations in the process can lead to variations in the final product’s properties.

3. Quality Control Measures

Strict quality control measures are essential to ensure that the FR4 material meets the required specifications. This includes regular testing of the material’s physical, mechanical, and electrical properties, as well as visual inspections for defects.

Key Properties of High-Quality FR4

High-quality FR4 should exhibit the following properties:

1. Mechanical Strength

FR4 should have excellent mechanical strength to withstand the rigors of PCB manufacturing and end-use applications. This includes high tensile strength, flexural strength, and impact resistance.

| Property | Typical Value |

|---|---|

| Tensile Strength | 310 MPa |

| Flexural Strength | 415 MPa |

| Izod Impact Strength | 120 J/m |

2. Dimensional Stability

FR4 should maintain its dimensional stability under various environmental conditions, such as temperature and humidity changes. This is crucial for maintaining the integrity of the PCB and preventing warping or twisting.

3. Electrical Insulation

As an insulating material, FR4 should have excellent electrical insulation properties. This includes high dielectric strength, low dielectric constant, and low dissipation factor.

| Property | Typical Value |

|---|---|

| Dielectric Strength | 50 kV/mm |

| Dielectric Constant (1 MHz) | 4.7 |

| Dissipation Factor (1 MHz) | 0.02 |

4. Thermal Stability

FR4 should have good thermal stability to withstand the heat generated during PCB operation and soldering processes. This includes a high glass transition temperature (Tg) and low thermal expansion coefficient.

| Property | Typical Value |

|---|---|

| Glass Transition Temperature (Tg) | 135°C |

| Coefficient of Thermal Expansion (CTE) | 14 ppm/°C |

FR4 Grades and Classifications

FR4 is available in various grades and classifications based on its performance characteristics and intended applications. Some common grades include:

1. Standard FR4

Standard FR4 is the most widely used grade and is suitable for general-purpose PCB applications. It offers a balanced combination of mechanical, electrical, and thermal properties at a cost-effective price point.

2. High Tg FR4

High Tg FR4 offers enhanced thermal stability compared to standard FR4. It is suitable for applications that require higher operating temperatures or increased resistance to thermal stress during soldering processes.

3. Halogen-Free FR4

Halogen-free FR4 is designed to meet the increasing demand for environmentally friendly and safer materials. It uses halogen-free flame retardants, which reduce the risk of toxic gas emissions during combustion.

Choosing the Right FR4 for Your Application

When selecting FR4 for your PCB application, consider the following factors:

-

Performance requirements: Determine the specific mechanical, electrical, and thermal requirements of your application and choose an FR4 grade that meets or exceeds these requirements.

-

Environmental conditions: Consider the environmental conditions your PCB will be exposed to, such as temperature, humidity, and chemical exposure, and select an FR4 grade that can withstand these conditions.

-

Cost considerations: Evaluate the cost implications of different FR4 grades and find a balance between performance and budget constraints.

-

Regulatory compliance: Ensure that the selected FR4 grade complies with relevant industry standards and regulations, such as UL, IPC, and RoHS.

Quality Assurance and Testing

To ensure the quality of FR4 material, manufacturers employ various quality assurance and testing methods. These include:

- Incoming raw material inspections

- In-process quality control checks

- Final product testing and certification

- Traceability and record-keeping

By adhering to strict quality assurance procedures, manufacturers can provide consistent and reliable FR4 material for PCB production.

Best Practices for Handling and Storage

Proper handling and storage of FR4 material are essential to maintain its quality and performance. Some best practices include:

- Store FR4 in a clean, dry, and temperature-controlled environment

- Avoid exposure to direct sunlight, moisture, and chemicals

- Use appropriate packaging materials to protect FR4 during transportation and storage

- Follow the manufacturer’s recommendations for handling and processing FR4

Troubleshooting Common FR4 Quality Issues

Despite stringent quality control measures, issues can occasionally arise with FR4 material. Some common quality issues and their potential causes include:

- Delamination: Improper lamination process, contamination, or moisture absorption

- Warping or twisting: Uneven resin distribution, excessive moisture, or improper handling

- Electrical failures: Contamination, voids, or conductive filaments in the material

- Discoloration: Exposure to high temperatures, UV light, or chemicals

By identifying the root cause of these issues, manufacturers can take corrective actions and prevent future occurrences.

Future Trends in FR4 Quality

As the electronics industry continues to evolve, so do the demands for higher quality and performance from FR4 material. Some future trends in FR4 quality include:

- Increased focus on halogen-free and environmentally friendly materials

- Development of high-performance FR4 grades for demanding applications, such as 5G, automotive, and aerospace

- Adoption of advanced manufacturing technologies, such as automation and data analytics, to improve quality and consistency

- Collaboration between material suppliers, PCB manufacturers, and end-users to optimize FR4 performance for specific applications

By staying at the forefront of these trends, manufacturers can ensure the continued improvement of FR4 quality and meet the ever-changing needs of the electronics industry.

Frequently Asked Questions (FAQ)

-

What is FR4, and why is it used in PCBs?

FR4 is a composite material made from woven fiberglass cloth and epoxy resin. It is used in PCBs due to its excellent mechanical, electrical, and thermal properties, as well as its flame-retardant characteristics. -

How does the quality of FR4 impact PCB performance?

The quality of FR4 directly affects the performance and reliability of PCBs. High-quality FR4 ensures better signal integrity, improved mechanical stability, and enhanced durability under various environmental conditions. -

What are the key properties to consider when evaluating FR4 quality?

When evaluating FR4 quality, consider its mechanical strength, dimensional stability, electrical insulation properties, and thermal stability. These properties are crucial for ensuring the optimal performance of PCBs. -

How can I ensure that I am using high-quality FR4 in my PCB application?

To ensure the use of high-quality FR4, work with reputable suppliers who adhere to strict quality control standards and can provide material certifications. Additionally, consider the specific requirements of your application and select an appropriate FR4 grade. -

What should I do if I encounter quality issues with FR4 material?

If you encounter quality issues with FR4 material, first identify the specific problem and its potential causes. Contact your supplier and provide detailed information about the issue. Work collaboratively with the supplier to determine the root cause and implement corrective actions to prevent future occurrences.

Conclusion

FR4 quality is a critical factor in the performance and reliability of PCBs. By understanding the factors that affect FR4 quality, the key properties to consider, and the best practices for handling and storage, you can make informed decisions when selecting FR4 for your PCB manufacturing needs. As the electronics industry continues to advance, staying up-to-date with the latest trends and developments in FR4 quality will be essential for success in this competitive market.

No responses yet