What are PCB Connectors?

PCB connectors are electrical components that facilitate the connection and disconnection of two or more parts of a printed circuit board (PCB). They allow for the transfer of power, signals, and data between different sections of the board or between the board and external devices. PCB connectors come in various shapes, sizes, and configurations to suit different applications and requirements.

Why are PCB Connectors Important?

PCB connectors play a vital role in ensuring the proper functioning and reliability of electronic devices. Some of the key reasons why PCB connectors are important include:

- Establishing reliable electrical connections

- Facilitating modular design and easy maintenance

- Enabling the connection of external devices and peripherals

- Providing mechanical support and stability

- Allowing for customization and flexibility in PCB design

Types of PCB Connectors

There are numerous types of PCB connectors available, each designed for specific applications and requirements. Let’s explore some of the most common and essential PCB Connector Types you should know in 2023.

1. Board-to-Board Connectors

Board-to-board (B2B) connectors are used to establish electrical connections between two PCBs. They are commonly employed in applications where space is limited, and a compact design is required. B2B connectors come in various types, such as:

- Mezzanine connectors

- Stacking connectors

- Edge connectors

- Vertical connectors

| Connector Type | Key Features | Applications |

|---|---|---|

| Mezzanine | – High-density – Parallel board arrangement – Various stack heights |

– Smartphones – Tablets – Wearables |

| Stacking | – Low profile – Board-to-board spacing – Various pin counts |

– IoT devices – Medical devices – Industrial controls |

| Edge | – Space-saving – High-speed signal transmission – Various contact types |

– Expansion cards – Modules – Blade servers |

| Vertical | – Perpendicular board arrangement – Space-saving – Various heights and pitches |

– Automotive electronics – Industrial controls – Telecommunications |

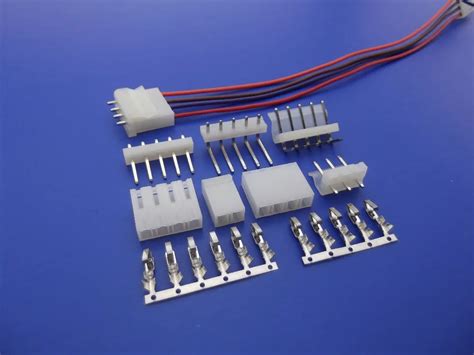

2. Wire-to-Board Connectors

Wire-to-board (W2B) connectors are used to establish electrical connections between a PCB and external wires or cables. They are essential for connecting power supplies, sensors, and other peripheral devices to the PCB. Some common types of W2B connectors include:

- Headers and sockets

- Terminal blocks

- JST connectors

- Molex connectors

| Connector Type | Key Features | Applications |

|---|---|---|

| Headers and Sockets | – Versatile – Various pin counts and pitches – Single or double row |

– Prototyping – Testing – Low-power applications |

| Terminal Blocks | – Secure wire connections – Screw or spring-loaded terminals – Various sizes and pole counts |

– Power supplies – Industrial controls – HVAC systems |

| JST Connectors | – Compact – Reliable – Various series and pin counts |

– Sensors – Batteries – Consumer electronics |

| Molex Connectors | – Robust – Diverse product range – Various pin counts and pitches |

– Automotive electronics – Industrial automation – Medical devices |

3. Input/Output (I/O) Connectors

Input/Output (I/O) connectors are used to establish connections between a PCB and external devices for data transfer, power supply, or signal transmission. Some common types of I/O connectors include:

- USB connectors

- HDMI connectors

- Ethernet connectors

- Audio connectors

| Connector Type | Key Features | Applications |

|---|---|---|

| USB | – High-speed data transfer – Various types (USB-A, USB-B, USB-C) – Power delivery |

– Computer peripherals – Mobile devices – Consumer electronics |

| HDMI | – High-definition video and audio – Various versions (1.4, 2.0, 2.1) – Ethernet support |

– Televisions – Monitors – Gaming consoles |

| Ethernet | – High-speed network connectivity – Various categories (Cat5, Cat6, Cat7) – PoE support |

– Routers – Switches – Network devices |

| Audio | – Analog or digital audio transmission – Various types (3.5mm, RCA, XLR) – Stereo or multichannel |

– Headphones – Speakers – Audio equipment |

4. Power Connectors

Power connectors are used to establish electrical connections for power supply between a PCB and external power sources or devices. Some common types of power connectors include:

- Barrel connectors

- IEC connectors

- ATX power connectors

- D-sub connectors

| Connector Type | Key Features | Applications |

|---|---|---|

| Barrel | – Cylindrical shape – Various diameters and lengths – Positive or negative center pin |

– Wall adapters – Chargers – Low-voltage devices |

| IEC | – International standard – Various types (C13, C14, C15, C16) – Removable power cords |

– Power supplies – Computers – Appliances |

| ATX Power | – Standard for PC power supplies – Various pin counts (20, 24) – 12V, 5V, and 3.3V outputs |

– Desktop computers – Servers – Workstations |

| D-sub | – Trapezoidal shape – Various sizes (DA-15, DB-25, DE-9) – Screw or slide locks |

– Serial ports – Parallel ports – Industrial controls |

5. RF Connectors

RF (Radio Frequency) connectors are used to establish connections for high-frequency signals between a PCB and external devices or antennas. Some common types of RF connectors include:

- SMA connectors

- BNC connectors

- U.FL connectors

- MCX connectors

| Connector Type | Key Features | Applications |

|---|---|---|

| SMA | – Threaded coupling – 50Ω or 75Ω impedance – High-frequency performance |

– Wireless communications – Test equipment – Microwave systems |

| BNC | – Bayonet locking – 50Ω or 75Ω impedance – Quick connect/disconnect |

– Video systems – Oscilloscopes – RF test equipment |

| U.FL | – Miniature size – Snap-on connection – High-frequency performance |

– Wi-Fi devices – Bluetooth modules – GPS receivers |

| MCX | – Snap-on connection – 50Ω impedance – Compact size |

– Wireless modules – Handheld devices – Automotive electronics |

How to Choose the Right PCB Connector

Choosing the right PCB connector for your application is crucial for ensuring reliable and efficient performance. When selecting a PCB connector, consider the following factors:

- Application requirements

- Data transfer speed

- Power rating

- Environmental conditions

-

Space constraints

-

Compatibility

- PCB layout and design

- Mating connectors

-

Cable or wire specifications

-

Reliability and durability

- Contact material and plating

- Insertion and withdrawal cycles

-

Vibration and shock resistance

-

Cost and availability

- Connector price

- Lead time and minimum order quantity

- Supplier reputation and support

Frequently Asked Questions (FAQ)

- What is the difference between through-hole and surface-mount PCB connectors?

-

Through-hole connectors have pins that are inserted into holes drilled in the PCB and soldered on the opposite side. Surface-mount connectors have contacts that are soldered directly onto the surface of the PCB. Surface-mount connectors are generally smaller and more suitable for high-density designs, while through-hole connectors offer greater mechanical strength and are easier to replace.

-

Can I use any type of wire with a PCB connector?

-

No, it’s essential to use wires that are compatible with the specific PCB connector you are using. Factors to consider include wire gauge, insulation material, and stranding. Always refer to the connector manufacturer’s specifications and recommendations when selecting wires for your application.

-

How do I determine the current rating of a PCB connector?

-

The current rating of a PCB connector depends on various factors, such as contact material, contact size, and the number of contacts. Connector manufacturers typically provide current ratings in their product specifications. It’s important to choose a connector with a current rating that is suitable for your application and to ensure that the connected wires and components can handle the required current as well.

-

What is the difference between a male and female PCB connector?

-

Male PCB connectors have exposed pins or contacts that are designed to be inserted into corresponding sockets or receptacles. Female PCB connectors have sockets or receptacles that are designed to receive the pins or contacts of a male connector. In general, male connectors are referred to as plugs, while female connectors are referred to as jacks or sockets.

-

How can I ensure a reliable connection between a PCB connector and its mating connector?

- To ensure a reliable connection, consider the following tips:

- Make sure the connectors are properly aligned and seated before mating them.

- Use connectors with a sufficient number of mating cycles for your application.

- Ensure that the connectors are rated for the environmental conditions they will be exposed to.

- Use locking mechanisms, such as screws or latches, to secure the connection if necessary.

- Follow the manufacturer’s recommended mating and unmating procedures.

Conclusion

PCB connectors are essential components in modern electronic devices, enabling reliable and efficient connections between various parts of a circuit board. With the wide range of PCB connector types available, it’s crucial to stay informed and choose the right connector for your specific application. By understanding the different types of PCB connectors, their key features, and applications, you can make informed decisions when designing or working with PCBs in 2023 and beyond.

No responses yet