Introduction to PCB Printers

In the world of electronics manufacturing, Printed Circuit Boards (PCBs) play a crucial role in connecting and supporting electronic components. As technology advances and the demand for smaller, more complex devices grows, the need for efficient and precise PCB manufacturing solutions becomes increasingly important. This is where PCB printers come into the picture, revolutionizing the way circuit boards are produced.

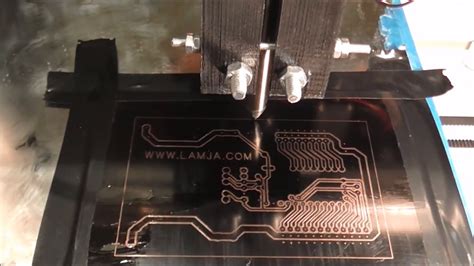

What is a PCB Printer?

A PCB printer is a specialized machine designed to print conductive traces and patterns onto a substrate material, such as FR4 or polyimide, to create a functional printed circuit board. These printers use various technologies, including inkjet printing, screen printing, and aerosol jet printing, to deposit conductive inks or pastes onto the substrate with high precision and accuracy.

Advantages of Using PCB Printers

PCB printers offer several advantages over traditional PCB manufacturing methods, such as etching and milling:

-

Rapid Prototyping: PCB printers enable quick and easy prototyping of circuit boards, allowing designers and engineers to test and refine their designs before committing to large-scale production.

-

Cost-Effective: For small to medium-sized production runs, PCB printers can be more cost-effective than traditional manufacturing methods, as they require fewer materials and less setup time.

-

Flexibility: PCB printers can handle a wide range of substrate materials and conductive inks, allowing for the creation of flexible, rigid, and even stretchable circuit boards.

-

High Precision: Advanced PCB printers can achieve trace widths as small as 50 microns, enabling the production of highly detailed and compact circuit boards.

Types of PCB Printers

There are several types of PCB printers available in the market, each with its own unique features and capabilities:

Inkjet PCB Printers

Inkjet PCB printers use a printhead to deposit small droplets of conductive ink onto the substrate material. These printers offer high precision and the ability to print on a variety of substrates, including flexible materials. Some popular inkjet PCB printers include:

- Nano Dimension DragonFly LDM

- Voltera V-One

- BotFactory SV2

Screen Printing PCB Printers

Screen printing PCB printers use a mesh screen to transfer conductive ink onto the substrate. This method is well-suited for larger trace widths and can produce circuit boards quickly and efficiently. Examples of screen printing PCB printers include:

- Asys Group X4

- Ekra X5

- MPM Momentum

Aerosol Jet PCB Printers

Aerosol jet PCB printers use a fine mist of conductive ink particles to create high-resolution traces on the substrate. This technology is particularly useful for creating circuits on non-planar surfaces and 3D structures. Some notable aerosol jet PCB printers include:

- Optomec Aerosol Jet 5X

- Neotech AMT 3D Printed Electronics

- TNO Emerald

Choosing the Right PCB Printer

When selecting a PCB printer for your manufacturing needs, consider the following factors:

-

Resolution and Accuracy: Determine the minimum trace width and spacing required for your PCB designs and choose a printer that can accommodate those specifications.

-

Substrate Compatibility: Ensure that the printer can handle the substrate materials you intend to use, such as FR4, polyimide, or flexible substrates.

-

Ink Compatibility: Consider the types of conductive inks the printer can use and their compatibility with your substrate materials and desired circuit properties.

-

Production Volume: Assess your expected production volume and choose a printer that can efficiently handle your needs, whether it’s small-scale prototyping or larger production runs.

-

Cost: Evaluate the upfront cost of the printer, as well as the ongoing costs of materials and maintenance, to determine the overall cost-effectiveness for your business.

PCB Printer Maintenance and Troubleshooting

To ensure optimal performance and longevity of your PCB printer, regular maintenance and troubleshooting are essential:

Maintenance Tips

-

Clean the Printhead: Regularly clean the printhead to prevent clogging and ensure consistent ink deposition. Follow the manufacturer’s recommended cleaning procedures and use appropriate cleaning solutions.

-

Calibrate the Printer: Periodically calibrate the printer to maintain accurate positioning and alignment of the printhead. This ensures precise trace placement and minimizes the risk of short circuits or open connections.

-

Store Inks Properly: Store conductive inks in a cool, dry place and follow the manufacturer’s guidelines for shelf life and storage conditions to maintain ink quality and performance.

Common Troubleshooting Issues

-

Clogged Printhead: If the printhead becomes clogged, it can result in inconsistent or missing traces. To resolve this issue, perform a thorough cleaning of the printhead and ensure that the ink is properly mixed and free of debris.

-

Poor Adhesion: If the printed traces are not adhering well to the substrate, check the compatibility of the ink and substrate materials, and ensure that the substrate surface is clean and free of contaminants. Adjusting the printer settings, such as the ink drop volume or the substrate temperature, may also improve adhesion.

-

Inconsistent Trace Width: Inconsistent trace widths can be caused by variations in ink viscosity, printhead clogging, or incorrect printer settings. Ensure that the ink is properly mixed and the printhead is clean, and adjust the printer settings as needed to achieve consistent trace widths.

Future of PCB Printers

As technology continues to advance, the future of PCB printers looks promising:

Emerging Trends

-

3D Printing: The integration of 3D printing technologies with PCB printers opens up new possibilities for creating complex, three-dimensional circuit structures and embedded electronics.

-

Intelligent Printing: The incorporation of artificial intelligence and machine learning algorithms into PCB printers can enable adaptive and self-optimizing printing processes, leading to higher quality and more efficient production.

-

Multi-Material Printing: The development of multi-material PCB printers that can simultaneously deposit conductive inks, insulators, and other functional materials will enable the creation of more advanced and integrated circuit boards.

Potential Applications

-

Wearable Electronics: PCB printers can enable the production of flexible and stretchable circuits for wearable devices, such as smartwatches, fitness trackers, and health monitoring systems.

-

Internet of Things (IoT): As the IoT continues to grow, PCB printers will play a crucial role in creating compact, low-cost, and customizable circuit boards for smart devices and sensors.

-

Aerospace and Defense: PCB printers can facilitate the production of high-performance, lightweight, and resilient circuit boards for aerospace and defense applications, such as satellites, drones, and military equipment.

FAQ

-

Q: What is the difference between inkjet and aerosol jet PCB printers?

A: Inkjet PCB printers use a printhead to deposit small droplets of conductive ink onto the substrate, while aerosol jet printers use a fine mist of ink particles. Aerosol jet printers can achieve higher resolutions and print on non-planar surfaces, but inkjet printers are generally more cost-effective and versatile. -

Q: Can PCB printers handle multi-layer circuit boards?

A: Yes, some advanced PCB printers can create multi-layer circuit boards by printing and curing multiple layers of conductive ink and insulating materials. However, the complexity and thickness of multi-layer boards may be limited compared to traditional manufacturing methods. -

Q: Are the circuits produced by PCB printers as reliable as those made with traditional methods?

A: When properly designed and printed, circuits produced by PCB printers can be just as reliable as those made with traditional methods. However, the reliability may depend on factors such as the quality of the conductive inks, the printer’s resolution and accuracy, and the post-printing curing and assembly processes. -

Q: How long does it take to print a circuit board using a PCB printer?

A: The printing time depends on the size and complexity of the circuit board, as well as the specific printer and settings used. Generally, PCB printers can produce a simple circuit board in a matter of minutes, while more complex designs may take several hours. -

Q: What is the typical resolution of a PCB printer?

A: The resolution of PCB printers varies depending on the technology used. Inkjet printers can typically achieve trace widths of 100-200 microns, while aerosol jet printers can produce traces as small as 10-50 microns. Screen printing PCB printers generally have lower resolutions, with trace widths of 200-500 microns.

Conclusion

PCB printers are revolutionizing the way circuit boards are manufactured, offering a fast, flexible, and cost-effective solution for prototyping and small to medium-scale production. With various technologies available, such as inkjet, screen printing, and aerosol jet printing, PCB printers can accommodate a wide range of design requirements and substrate materials.

As the demand for smaller, more complex electronic devices continues to grow, PCB printers will play an increasingly important role in the electronics manufacturing industry. By staying up-to-date with the latest trends and technologies in PCB printing, manufacturers can remain competitive and meet the evolving needs of their customers.

Whether you’re a small startup or a large enterprise, investing in a PCB printer can help streamline your production process, reduce costs, and accelerate time-to-market for your electronic products. By carefully considering your specific requirements and choosing the right PCB printer for your needs, you can unlock the full potential of this innovative manufacturing solution.

No responses yet