What is a Start-Stop Circuit?

A start-stop circuit is an electrical control system that allows the user to start and stop a machine or process with the push of a button. It is a fundamental control circuit found in many industrial applications, such as motor control, conveyor systems, and automation equipment. The primary purpose of a start-stop circuit is to provide a safe and reliable means of controlling the operation of a machine or process.

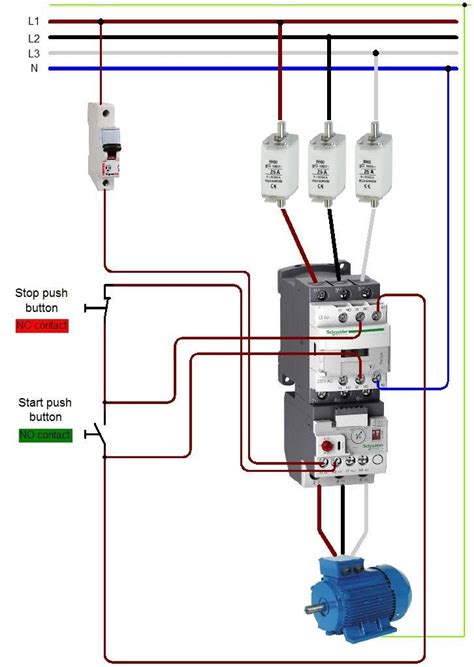

Components of a Start-Stop Circuit

A typical start-stop circuit consists of the following components:

1. Start Button

The start button is a normally open (NO) momentary switch that initiates the operation of the circuit when pressed. When the start button is pressed, it completes the circuit, allowing current to flow through the contactor coil, which in turn energizes the contactor and starts the machine or process.

2. Stop Button

The stop button is a normally closed (NC) momentary switch that interrupts the operation of the circuit when pressed. When the stop button is pressed, it breaks the circuit, cutting off the current to the contactor coil, which de-energizes the contactor and stops the machine or process.

3. Contactor

A contactor is an electromechanical device that functions as a high-power relay. It consists of a coil and a set of contacts. When the coil is energized, it creates a magnetic field that attracts the movable contacts, closing the circuit and allowing power to flow to the machine or process. When the coil is de-energized, the contacts open, interrupting the power supply.

4. Overload Protection

Overload protection is a device that safeguards the machine or process from damage due to excessive current. It monitors the current drawn by the motor or other load and trips the circuit if the current exceeds a predetermined value. Overload protection can be in the form of thermal overload relays, electronic overload relays, or fuses.

5. Pilot Light

A pilot light is an indicator lamp that provides visual feedback on the status of the circuit. It is typically connected in parallel with the contactor coil and illuminates when the circuit is energized, indicating that the machine or process is running.

Working Principle of a Start-Stop Circuit

The working principle of a start-stop circuit can be explained in the following steps:

- When the start button is pressed, it completes the circuit, allowing current to flow through the contactor coil.

- The energized contactor coil creates a magnetic field, attracting the movable contacts and closing the power circuit to the machine or process.

- The machine or process starts running, and the pilot light illuminates, indicating that the circuit is energized.

- When the stop button is pressed, it breaks the circuit, cutting off the current to the contactor coil.

- The contactor coil de-energizes, and the movable contacts open, interrupting the power supply to the machine or process.

- The machine or process stops, and the pilot light turns off, indicating that the circuit is de-energized.

Control of Start-stop Circuits

Start-stop circuits can be controlled using various methods, depending on the application and the level of automation required. Some common control methods include:

1. Manual Control

In manual control, the start and stop buttons are operated by a human operator. This method is suitable for applications where the machine or process needs to be started and stopped manually, such as in small workshops or maintenance tasks.

2. Automatic Control

Automatic control involves the use of sensors, timers, or other control devices to start and stop the circuit based on predetermined conditions. For example, a temperature sensor can be used to start a cooling system when the temperature exceeds a certain value and stop it when the temperature drops below a set point.

3. PLC Control

Programmable Logic Controllers (PLCs) are widely used in industrial automation to control start-stop circuits. PLCs are microprocessor-based devices that can be programmed to perform a wide range of control functions, including starting and stopping machines or processes based on various inputs and outputs. PLCs offer flexibility, reliability, and ease of programming, making them a popular choice for complex control systems.

Safety Considerations in Start-Stop Circuits

Safety is a critical aspect of start-stop circuits, as they are often used to control machines or processes that can pose a risk to operators or the environment. Some key safety considerations include:

1. Emergency Stop

An emergency stop (E-stop) button is a mandatory safety feature in start-stop circuits. It is a red, mushroom-headed button that, when pressed, immediately cuts off power to the machine or process, bringing it to a safe stop. E-stop buttons must be easily accessible and clearly labeled.

2. Interlocking

Interlocking is a safety feature that prevents the machine or process from starting unless certain conditions are met. For example, a guard interlocking switch can be used to ensure that the machine cannot start unless the safety guard is in place.

3. Redundancy

Redundancy is the use of multiple devices or systems to perform the same function, providing a backup in case of failure. In start-stop circuits, redundancy can be implemented by using multiple contactors or by incorporating a secondary control circuit that can take over in case of a primary circuit failure.

4. Proper Wiring and Grounding

Proper wiring and grounding are essential to ensure the safe operation of start-stop circuits. All components must be correctly sized and rated for the application, and the circuit must be properly grounded to prevent electric shock hazards.

Applications of Start-Stop Circuits

Start-stop circuits are used in a wide range of industrial applications, including:

- Motor control: Starting and stopping electric motors in various machines and equipment.

- Conveyor systems: Controlling the operation of conveyor belts in manufacturing and logistics.

- Pumps and compressors: Controlling the operation of pumps and compressors in process industries.

- HVAC systems: Controlling the operation of heating, ventilation, and air conditioning systems in buildings.

- Packaging machinery: Controlling the operation of packaging machines in the food and beverage industry.

Troubleshooting Start-Stop Circuits

Troubleshooting start-stop circuits involves identifying and resolving issues that prevent the circuit from operating correctly. Some common problems and their solutions include:

1. Machine does not start

- Check the power supply to ensure that the circuit is receiving the correct voltage.

- Verify that the start button is functioning correctly and that the contacts are not damaged or stuck.

- Check the contactor coil for continuity and replace it if defective.

- Ensure that the overload protection device is not tripped and that it is sized correctly for the application.

2. Machine does not stop

- Check the stop button to ensure that it is functioning correctly and that the contacts are not damaged or stuck.

- Verify that the contactor contacts are opening when the stop button is pressed.

- Check for any shorts or crossed wires in the control circuit that may be preventing the contactor from de-energizing.

3. Overload protection trips frequently

- Verify that the overload protection device is sized correctly for the application.

- Check the motor or other load for any mechanical issues, such as binding or excessive friction.

- Ensure that the load is not exceeding the rated capacity of the motor or other components.

Maintenance of Start-Stop Circuits

Regular maintenance is essential to ensure the reliable and safe operation of start-stop circuits. Some key maintenance tasks include:

-

Inspecting and cleaning contacts: Regularly inspect the contacts of the start and stop buttons, as well as the contactor, for any signs of wear, pitting, or corrosion. Clean the contacts with a suitable electrical contact cleaner if necessary.

-

Checking connections: Verify that all connections in the circuit are tight and secure, and that there are no signs of overheating or damage.

-

Testing components: Periodically test the function of the start and stop buttons, contactor, and overload protection device to ensure that they are operating correctly.

-

Lubricating moving parts: If the contactor or other components have moving parts, ensure that they are properly lubricated according to the manufacturer’s recommendations.

-

Keeping records: Maintain accurate records of all maintenance tasks performed, including the date, the components inspected or replaced, and any issues found.

Frequently Asked Questions (FAQ)

1. What is the difference between a normally open (NO) and normally closed (NC) contact?

A normally open (NO) contact is open when the circuit is de-energized and closes when the circuit is energized. A normally closed (NC) contact is closed when the circuit is de-energized and opens when the circuit is energized.

2. Can a start-stop circuit be used with a three-phase motor?

Yes, start-stop circuits can be used with three-phase motors. In this case, the contactor will have three sets of power contacts, one for each phase of the motor.

3. What is the purpose of the overload protection device in a start-stop circuit?

The overload protection device safeguards the motor or other load from damage due to excessive current. It monitors the current drawn by the load and trips the circuit if the current exceeds a predetermined value, preventing the motor from overheating or burning out.

4. How often should start-stop circuit components be inspected and maintained?

The frequency of inspection and maintenance depends on the application and the environment in which the circuit operates. As a general guideline, start-stop circuits should be inspected and maintained at least once every six months, or more frequently if the circuit is subject to heavy use or harsh conditions.

5. Can a PLC be used to control multiple start-stop circuits?

Yes, a PLC can be programmed to control multiple start-stop circuits simultaneously. This allows for complex control strategies and the integration of multiple machines or processes into a single automated system.

Conclusion

Start-stop circuits are a fundamental control system used in a wide range of industrial applications. They provide a safe and reliable means of starting and stopping machines or processes with the push of a button. Understanding the components, working principle, and control methods of start-stop circuits is essential for designing, troubleshooting, and maintaining these systems.

Safety is a critical consideration in start-stop circuits, and features such as emergency stop buttons, interlocking, redundancy, and proper wiring and grounding must be incorporated to ensure the safe operation of the controlled equipment.

Regular maintenance, including inspecting and cleaning contacts, checking connections, testing components, lubricating moving parts, and keeping accurate records, is essential to ensure the reliable and safe operation of start-stop circuits over time.

As industrial automation continues to advance, the use of PLCs and other sophisticated control methods will likely become more prevalent in start-stop circuits. However, the basic principles and components of these circuits will remain the same, making a strong understanding of start-stop circuits an invaluable skill for professionals in the industrial control field.

| Component | Function |

|---|---|

| Start Button | Normally open (NO) momentary switch that initiates the operation of the circuit when pressed |

| Stop Button | Normally closed (NC) momentary switch that interrupts the operation of the circuit when pressed |

| Contactor | Electromechanical device that functions as a high-power relay, consisting of a coil and a set of contacts |

| Overload Protection | Device that safeguards the machine or process from damage due to excessive current |

| Pilot Light | Indicator lamp that provides visual feedback on the status of the circuit |

| Control Method | Description |

|---|---|

| Manual Control | Start and stop buttons are operated by a human operator |

| Automatic Control | Sensors, timers, or other control devices are used to start and stop the circuit based on predetermined conditions |

| PLC Control | Programmable Logic Controllers (PLCs) are used to control start-stop circuits, offering flexibility, reliability, and ease of programming |

No responses yet