What are Start-stop Circuits?

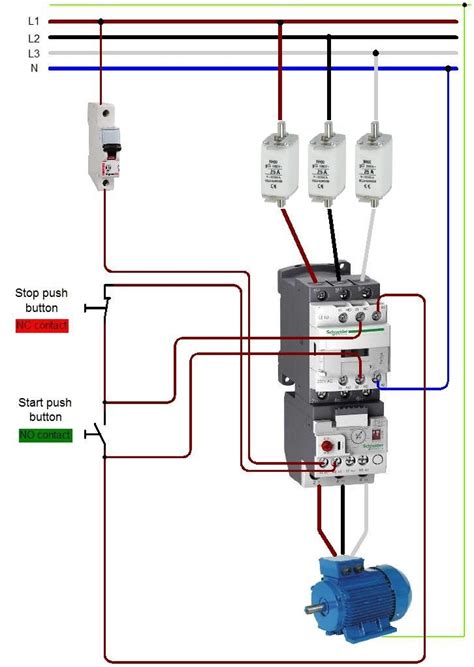

Start-stop circuits, also known as control circuits, are designed to initiate and halt the operation of electrical devices or machines. These circuits typically consist of push buttons, relays, contactors, and other components that work together to control the flow of electricity to the desired load.

The primary purpose of a start-stop circuit is to provide a safe and convenient way to control the operation of a device or machine. By pressing a start button, the circuit is energized, allowing current to flow to the load. Conversely, pressing a stop button de-energizes the circuit, cutting off the power supply to the load.

Types of Start-stop Circuits

There are several types of start-stop circuits, each designed to meet specific requirements and applications. Some of the most common types include:

1. Momentary Start-stop Circuits

Momentary start-stop circuits rely on push buttons that only remain in the “on” position while being pressed. When the button is released, it returns to its default “off” position. This type of circuit is often used in applications where the operator needs to maintain control over the device or machine, such as in a drill press or a conveyor belt system.

2. Maintained Start-stop Circuits

Maintained start-stop circuits utilize push buttons that latch in the “on” position when pressed and remain in that state until the stop button is pressed. This type of circuit is commonly used in applications where the device or machine needs to run continuously without constant operator intervention, such as in a pump or a fan.

3. Three-wire Control Circuits

Three-wire control circuits are a popular choice for industrial applications, as they provide an added layer of safety. In this type of circuit, a separate wire is used for the start and stop functions, while the third wire is used as a common connection. This configuration ensures that the circuit cannot be accidentally energized by a single wire fault.

4. Reversing Start-stop Circuits

Reversing start-stop circuits are used to control devices or machines that require bidirectional motion, such as motors. These circuits incorporate forward and reverse push buttons, along with the necessary contactors and interlocks to ensure safe and reliable operation.

Components of Start-stop Circuits

Start-stop circuits are composed of various components that work together to control the flow of electricity. Some of the key components include:

1. Push Buttons

Push buttons are the primary input devices in start-stop circuits. They are used to initiate and halt the operation of the connected device or machine. Push buttons come in various types, such as momentary, maintained, and illuminated, depending on the specific application requirements.

2. Relays and Contactors

Relays and contactors are electromechanical switches that are used to control the flow of electricity in start-stop circuits. When energized, these devices close their contacts, allowing current to flow to the load. Relays are typically used for low-power applications, while contactors are used for higher-power applications.

3. Overload Protection Devices

Overload protection devices, such as thermal overload relays and fuses, are used to safeguard the start-stop circuit and the connected load from excessive current. These devices monitor the current flowing through the circuit and automatically disconnect the power supply if the current exceeds a predetermined threshold.

4. Indicating Lights

Indicating lights are used to provide visual feedback on the status of the start-stop circuit and the connected device or machine. These lights can be used to indicate whether the circuit is energized, whether the device is running, or to signal any faults or alarms.

Applications of Start-stop Circuits

Start-stop circuits find applications in a wide range of industries and settings. Some of the most common applications include:

1. Industrial Machinery

Start-stop circuits are extensively used in industrial machinery, such as conveyor systems, packaging machines, and production lines. These circuits provide a safe and efficient means to control the operation of the machinery, ensuring smooth and uninterrupted production processes.

2. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often employ start-stop circuits to control the operation of fans, pumps, and compressors. These circuits enable the system to maintain the desired temperature and humidity levels while optimizing energy consumption.

3. Pumping Systems

Start-stop circuits are commonly used in pumping systems, such as those found in water treatment plants, irrigation systems, and industrial processes. These circuits control the operation of the pumps, ensuring that the desired flow rates and pressures are maintained.

4. Material Handling Equipment

Material handling equipment, such as cranes, hoists, and elevators, relies on start-stop circuits for safe and efficient operation. These circuits enable the operator to control the movement of the equipment, ensuring precise positioning and smooth handling of materials.

Troubleshooting Start-stop Circuits

When working with start-stop circuits, it is essential to be familiar with common troubleshooting techniques to identify and resolve issues efficiently. Some of the key steps in troubleshooting start-stop circuits include:

1. Visual Inspection

Begin by visually inspecting the circuit components for any signs of damage, loose connections, or burnt components. Check the wiring for any frayed or exposed conductors, and ensure that all terminals are securely fastened.

2. Continuity Testing

Use a multimeter to test the continuity of the circuit components, such as push buttons, relays, and contactors. This will help identify any open or short circuits that may be preventing the circuit from functioning correctly.

3. Voltage Measurements

Measure the voltage at various points in the circuit to ensure that the correct voltage is being supplied to the components. Check the voltage across the coil of relays and contactors to verify that they are receiving the proper voltage to operate.

4. Current Measurements

Use a clamp meter or current probe to measure the current flowing through the circuit. Compare the measured values to the expected values based on the load specifications. Excessive current draw may indicate a fault in the load or the circuit components.

5. Logical Troubleshooting

Follow the logical flow of the circuit, starting from the power source and working towards the load. Identify the function of each component and test them individually to isolate the faulty component. Use the schematic diagram as a reference to understand the circuit’s intended operation.

Frequently Asked Questions (FAQ)

1. What is the difference between a relay and a contactor in a start-stop circuit?

Relays and contactors are both electromechanical switches used in start-stop circuits, but they differ in their power handling capabilities. Relays are typically used for low-power applications, such as control circuits, while contactors are used for higher-power applications, such as motor control.

2. Can a start-stop circuit be used with an AC or DC power supply?

Yes, start-stop circuits can be designed to work with either AC or DC power supplies. The choice of components, such as push buttons, relays, and contactors, will depend on the specific voltage and current requirements of the application.

3. What is the purpose of overload protection in a start-stop circuit?

Overload protection devices, such as thermal overload relays and fuses, are used to safeguard the start-stop circuit and the connected load from excessive current. These devices monitor the current flowing through the circuit and automatically disconnect the power supply if the current exceeds a predetermined threshold, preventing damage to the components and ensuring safe operation.

4. How can I prevent accidental startup in a start-stop circuit?

To prevent accidental startup in a start-stop circuit, you can implement safety features such as emergency stop buttons, interlocks, and lockout-tagout procedures. These measures ensure that the circuit cannot be energized unintentionally, protecting the operator and the equipment.

5. What should I do if my start-stop circuit is not functioning correctly?

If your start-stop circuit is not functioning correctly, begin by performing a visual inspection of the components and wiring. Check for any signs of damage, loose connections, or burnt components. Use a multimeter to test the continuity of the components and measure the voltage and current at various points in the circuit. Refer to the schematic diagram and follow the logical flow of the circuit to isolate the faulty component. If the issue persists, consult with a qualified electrician or technician for further assistance.

Conclusion

Start-stop circuits play a crucial role in controlling the operation of electrical devices and machines across various industries. By understanding the fundamental principles, types, components, and applications of start-stop circuits, you can design, implement, and troubleshoot these circuits effectively.

Remember to prioritize safety when working with start-stop circuits, and always follow best practices for installation, maintenance, and troubleshooting. With the knowledge gained from this article, you are well-equipped to tackle start-stop circuit projects and ensure their reliable and efficient operation.

| Component | Function |

|---|---|

| Push Buttons | Initiate and halt the operation of the connected device or machine |

| Relays | Control the flow of electricity in low-power applications |

| Contactors | Control the flow of electricity in higher-power applications |

| Overload Protection Devices | Safeguard the circuit and load from excessive current |

| Indicating Lights | Provide visual feedback on the status of the circuit and connected device |

Table 1: Key components of start-stop circuits and their functions

| Type of Start-stop Circuit | Application |

|---|---|

| Momentary | Operator needs to maintain control over the device or machine |

| Maintained | Device or machine needs to run continuously without constant operator intervention |

| Three-wire Control | Provides an added layer of safety in industrial applications |

| Reversing | Controls devices or machines that require bidirectional motion |

Table 2: Types of start-stop circuits and their applications

By incorporating these tables and following the provided guidelines, you now have a comprehensive article on start-stop circuits that covers the essential aspects and provides valuable information for your readers.

No responses yet