What is a DPDT Relay?

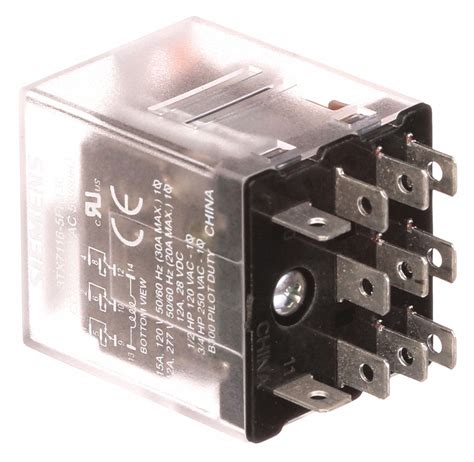

A Double Pole Double Throw (DPDT) relay is an electromechanical switch that uses an electromagnet to control two sets of electrical contacts, each capable of switching between two positions. When the relay coil is energized, the contacts change state, allowing current to flow through the connected circuits. DPDT relays are widely used in various applications, such as automotive systems, industrial control, and home automation.

Key Features of DPDT Relays

- Two sets of contacts (double pole)

- Each set of contacts can switch between two positions (double throw)

- Electrically operated using an electromagnet

- Isolates low-power control circuits from high-power loads

- Available in various coil voltages and contact ratings

How Does a DPDT Relay Work?

A DPDT relay consists of several main components:

- Coil: An electromagnet that, when energized, generates a magnetic field to actuate the contacts.

- Armature: A movable metal plate that is attracted to the coil when energized.

- Contacts: Two sets of electrical contacts (usually made of silver or gold alloy) that switch between two positions when the armature moves.

- Spring: A mechanical spring that returns the armature and contacts to their default position when the coil is de-energized.

When a voltage is applied to the coil, it generates a magnetic field that attracts the armature. As the armature moves, it causes the contacts to switch from their default position to the energized position. When the voltage is removed from the coil, the spring returns the armature and contacts to their default position.

DPDT Relay Contact Configurations

DPDT relays have two sets of contacts, each with three terminals:

- Common (COM): The central terminal that connects to the moving contact.

- Normally Closed (NC): The terminal that is connected to the common when the relay is not energized.

- Normally Open (NO): The terminal that is connected to the common when the relay is energized.

The following table illustrates the state of the contacts in a DPDT relay:

| Coil State | Contact Set 1 | Contact Set 2 |

|---|---|---|

| De-energized | COM1 ↔ NC1 | COM2 ↔ NC2 |

| Energized | COM1 ↔ NO1 | COM2 ↔ NO2 |

Types of DPDT Relays

DPDT relays come in various types, each designed for specific applications and environments:

1. General-Purpose Relays

General-purpose DPDT relays are suitable for a wide range of applications, including:

- Industrial control systems

- Home automation

- Automotive systems

- Lighting control

These relays typically have a compact design, low coil power consumption, and moderate contact ratings.

2. Power Relays

Power DPDT relays are designed to handle high-current loads, such as:

- Electric motors

- Heating elements

- High-power lighting systems

These relays feature heavy-duty contacts and robust construction to withstand the demands of high-power switching.

3. Automotive Relays

Automotive DPDT relays are specifically designed for use in vehicles, with features such as:

- Resistance to vibration and shock

- Wide operating temperature range

- Compact size

- High reliability

Common applications for automotive DPDT relays include:

- Headlight and fog light control

- Horn control

- Fuel pump control

- Starter motor control

4. Latching Relays

Latching DPDT relays, also known as bistable relays, maintain their state even when the coil is not energized. These relays use a permanent magnet or mechanical latch to hold the contacts in position, requiring only a momentary pulse to switch states. Latching relays are useful in applications where power consumption is a concern or when the relay state must be maintained during power outages.

5. Reed Relays

Reed DPDT relays use a pair of ferromagnetic reeds sealed in a glass envelope filled with an inert gas. When the coil is energized, the reeds are magnetized and attract each other, closing the contacts. Reed relays offer several advantages:

- High switching speed

- Low coil power consumption

- Long lifespan

- Ability to switch low-level signals

However, reed relays have lower contact ratings compared to other types of DPDT relays.

Selecting the Right DPDT Relay

When choosing a DPDT relay for your application, consider the following factors:

- Coil voltage and power consumption

- Contact rating (voltage and current)

- Switching speed

- Mechanical lifespan (number of switching cycles)

- Operating temperature range

- Mounting options (PCB, socket, or panel mount)

- Physical size and weight

- Cost

It’s essential to choose a relay that meets the specific requirements of your application to ensure reliable operation and longevity.

DPDT Relay Applications

DPDT relays are used in a wide range of applications across various industries:

1. Industrial Control Systems

- Motor control

- Process control

- Programmable Logic Controllers (PLCs)

- Safety interlocks

2. Home Automation

- Lighting control

- HVAC control

- Security systems

- Smart appliances

3. Automotive Systems

- Headlight and fog light control

- Horn control

- Fuel pump control

- Starter motor control

4. Telecommunications

- Switching between primary and backup power sources

- Switching between communication channels

- Line testing and monitoring

5. Medical Equipment

- Switching between primary and backup power sources

- Controlling multiple functions in medical devices

- Isolation of low-voltage control circuits from high-voltage loads

Wiring and Installing DPDT Relays

Proper wiring and installation are crucial for the safe and reliable operation of DPDT relays. Follow these general guidelines:

- Ensure the relay coil voltage matches the control circuit voltage.

- Use the appropriate wire gauge for the expected current through the contacts.

- Protect the relay contacts from inductive kickback using suppression devices (e.g., diodes or varistors) when switching inductive loads.

- Provide adequate heat dissipation and ventilation to prevent overheating.

- Use proper mounting techniques to minimize vibration and shock.

- Follow the manufacturer’s installation instructions and adhere to local electrical codes and regulations.

Troubleshooting DPDT Relays

If a DPDT relay is not functioning correctly, consider the following troubleshooting steps:

- Check the coil voltage and ensure it matches the relay specification.

- Verify that the coil is receiving the correct voltage using a multimeter.

- Inspect the relay contacts for signs of wear, pitting, or contamination. Clean or replace the contacts as necessary.

- Check the connected wiring for loose connections, short circuits, or open circuits.

- Ensure the relay is properly mounted and not subject to excessive vibration or shock.

- Verify that the relay is not being operated beyond its specified contact ratings or switching frequency.

Frequently Asked Questions (FAQ)

1. What is the difference between a DPDT relay and an SPDT Relay?

A DPDT (Double Pole Double Throw) relay has two sets of contacts, each capable of switching between two positions. An SPDT (Single Pole Double Throw) relay has only one set of contacts that can switch between two positions.

2. Can a DPDT relay be used as an SPDT relay?

Yes, a DPDT relay can be used as an SPDT relay by simply using only one set of contacts and leaving the other set unused.

3. What is the purpose of the coil in a DPDT relay?

The coil in a DPDT relay is an electromagnet that, when energized, generates a magnetic field to actuate the contacts, causing them to switch positions.

4. How do I protect a DPDT relay from inductive kickback?

To protect a DPDT relay from inductive kickback, use suppression devices such as diodes or varistors connected across the relay coil or in parallel with the inductive load.

5. What is the lifespan of a DPDT relay?

The lifespan of a DPDT relay depends on factors such as the contact rating, switching frequency, and operating environment. Typical mechanical lifespans range from 100,000 to 10,000,000 switching cycles. Always consult the manufacturer’s specifications for accurate lifespan information.

Conclusion

DPDT relays are versatile and reliable electromechanical switches used in a wide range of applications, from industrial control systems to home automation and automotive systems. By understanding the working principles, types, and selection criteria for DPDT relays, you can choose the most appropriate relay for your specific application and ensure its proper installation and troubleshooting. When used correctly, DPDT relays offer an effective solution for switching between multiple circuits and isolating low-power control signals from high-power loads.

No responses yet