Table of Contents

- Introduction to PCB Materials

- Factors to Consider When Choosing PCB Materials

- Types of PCB Materials

- FR-4

- High-Frequency Materials

- Flexible PCB Materials

- Metal Core PCB Materials

- Ceramic PCB Materials

- PCB Material Properties

- Dielectric Constant

- Loss Tangent

- Thermal Conductivity

- Coefficient of Thermal Expansion (CTE)

- Moisture Absorption

- PCB Material Selection Guide

- Factors to Consider

- Material Selection Flowchart

- PCB Material Comparison Table

- Frequently Asked Questions (FAQ)

- Conclusion

- References

Introduction to PCB Materials

PCB materials are the foundation of printed circuit boards, providing the insulating substrate and conductive layers necessary for interconnecting electronic components. The choice of PCB material directly impacts the electrical, thermal, and mechanical properties of the final product. Understanding the characteristics and limitations of different PCB materials is crucial for designing reliable and high-performance electronic devices.

Factors to Consider When Choosing PCB Materials

When selecting PCB materials, several factors must be considered to ensure optimal performance and reliability:

-

Electrical Requirements: Consider the dielectric constant, loss tangent, and dielectric strength of the material to ensure proper signal integrity and impedance control.

-

Thermal Requirements: Evaluate the thermal conductivity and coefficient of thermal expansion (CTE) of the material to manage heat dissipation and minimize thermal stress.

-

Mechanical Requirements: Consider the material’s strength, flexibility, and dimensional stability to withstand physical stresses and maintain structural integrity.

-

Environmental Conditions: Assess the material’s resistance to moisture, chemicals, and extreme temperatures to ensure reliable operation in the intended environment.

-

Manufacturing Process: Consider the compatibility of the material with the desired manufacturing processes, such as soldering, drilling, and plating.

-

Cost: Evaluate the cost of the material in relation to the project’s budget and performance requirements.

Types of PCB Materials

There are various types of PCB materials available, each with its own unique properties and applications. Let’s explore some of the most common PCB materials:

FR-4

FR-4 (Flame Retardant 4) is the most widely used PCB material. It is a composite material made of woven fiberglass cloth impregnated with an epoxy resin. FR-4 offers good electrical insulation, mechanical strength, and thermal stability. It is suitable for a wide range of applications, including consumer electronics, industrial control systems, and telecommunications equipment.

Key properties of FR-4:

– Dielectric Constant: 4.2-4.6 at 1 MHz

– Loss Tangent: 0.02 at 1 MHz

– Thermal Conductivity: 0.3-0.4 W/mK

– Glass Transition Temperature (Tg): 130-140°C

– Coefficient of Thermal Expansion (CTE): 14-16 ppm/°C

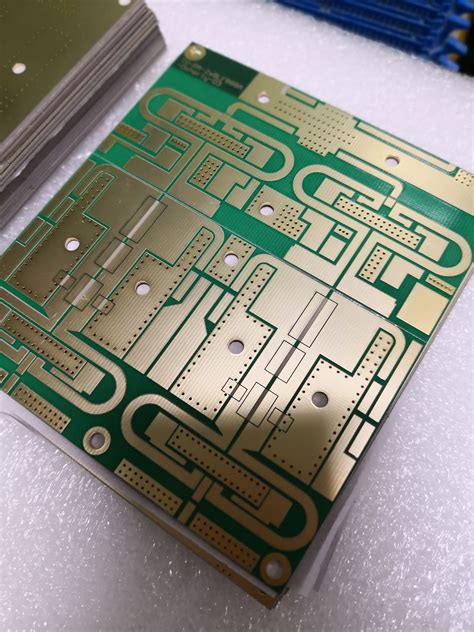

High-Frequency Materials

For applications that require high-frequency operation, such as RF and microwave devices, specialized PCB materials with low dielectric constant and low loss tangent are used. These materials minimize signal loss and maintain signal integrity at high frequencies. Examples of high-frequency PCB materials include Rogers RO4000 series, Isola IS680, and Taconic TLX.

Key properties of high-frequency materials:

– Dielectric Constant: 2.5-3.5 at 10 GHz

– Loss Tangent: 0.002-0.005 at 10 GHz

– Thermal Conductivity: 0.5-0.7 W/mK

– CTE: 10-20 ppm/°C

Flexible PCB Materials

Flexible PCB materials are used in applications that require bending, folding, or flexing of the circuit board. These materials are typically made of polyimide or polyester films with copper foils laminated on one or both sides. Flexible PCB materials offer high flexibility, lightweight, and resistance to vibration and shock. Examples of flexible PCB materials include DuPont Pyralux, 3M Flexible Circuits, and Sheldahl Novaflex.

Key properties of flexible PCB materials:

– Dielectric Constant: 3.2-3.5 at 1 MHz

– Loss Tangent: 0.002-0.004 at 1 MHz

– Thermal Conductivity: 0.2-0.3 W/mK

– CTE: 20-30 ppm/°C

Metal Core PCB Materials

Metal core PCB materials are used in applications that require efficient heat dissipation, such as high-power LED lighting and power electronics. These materials consist of a metal substrate, typically aluminum, with a thin dielectric layer and copper foil on top. The metal substrate acts as a heat sink, rapidly transferring heat away from the components. Examples of metal core PCB materials include Bergquist Thermal Clad and Arlon Metal Core.

Key properties of metal core PCB materials:

– Dielectric Constant: 3.5-4.5 at 1 MHz

– Loss Tangent: 0.01-0.02 at 1 MHz

– Thermal Conductivity: 1-3 W/mK

– CTE: 6-10 ppm/°C

Ceramic PCB Materials

Ceramic PCB materials are used in high-temperature and high-reliability applications, such as aerospace, military, and medical devices. These materials are made of ceramic substrates, such as alumina (Al2O3) or aluminum nitride (AlN), with conductive traces screen-printed or plated on the surface. Ceramic PCB materials offer excellent thermal stability, high thermal conductivity, and low dielectric loss.

Key properties of ceramic PCB materials:

– Dielectric Constant: 9-10 at 1 MHz (Al2O3), 8-9 at 1 MHz (AlN)

– Loss Tangent: 0.0001-0.0003 at 1 MHz

– Thermal Conductivity: 20-30 W/mK (Al2O3), 150-180 W/mK (AlN)

– CTE: 6-8 ppm/°C (Al2O3), 4-5 ppm/°C (AlN)

PCB Material Properties

To make informed decisions when selecting PCB materials, it is important to understand the key properties that affect the performance and reliability of the circuit board. Let’s discuss some of the most important PCB material properties:

Dielectric Constant

The dielectric constant, also known as relative permittivity (εr), is a measure of a material’s ability to store electrical energy. It is the ratio of the material’s permittivity to the permittivity of vacuum. A lower dielectric constant is desirable for high-frequency applications to minimize signal propagation delay and maintain signal integrity.

Loss Tangent

The loss tangent, also known as dissipation factor (tan δ), is a measure of a material’s ability to dissipate electrical energy as heat. It represents the ratio of the imaginary part to the real part of the material’s complex permittivity. A lower loss tangent is desirable to minimize signal loss and maintain signal integrity, especially at high frequencies.

Thermal Conductivity

Thermal conductivity is a measure of a material’s ability to conduct heat. It represents the rate at which heat is transferred through the material per unit thickness and temperature difference. A higher thermal conductivity is desirable for applications that generate significant heat, as it helps to dissipate heat more efficiently and prevent thermal damage to components.

Coefficient of Thermal Expansion (CTE)

The coefficient of thermal expansion (CTE) is a measure of a material’s dimensional change in response to temperature changes. It represents the fractional change in length per unit change in temperature. A lower CTE is desirable to minimize thermal stress and prevent cracking or delamination of the PCB during temperature cycling.

Moisture Absorption

Moisture absorption is a measure of a material’s ability to absorb moisture from the environment. It is expressed as a percentage of weight gain after exposure to a specified humidity level for a specified time. A lower moisture absorption is desirable to prevent dimensional changes, degradation of electrical properties, and delamination of the PCB.

PCB Material Selection Guide

Selecting the right PCB material for your project involves considering various factors and balancing the trade-offs between performance, reliability, and cost. Here’s a step-by-step guide to help you choose the most suitable PCB material:

Factors to Consider

- Electrical Requirements:

- Dielectric constant: Choose a material with a suitable dielectric constant for your application’s frequency range and signal integrity requirements.

- Loss tangent: Select a material with a low loss tangent to minimize signal loss and maintain signal integrity, especially at high frequencies.

-

Dielectric strength: Ensure the material has sufficient dielectric strength to withstand the expected voltage levels.

-

Thermal Requirements:

- Thermal conductivity: Consider the heat generation of your components and choose a material with adequate thermal conductivity to dissipate heat efficiently.

- CTE: Select a material with a CTE that closely matches the CTE of your components to minimize thermal stress and prevent cracking or delamination.

-

Glass transition temperature (Tg): Ensure the material’s Tg is higher than the expected operating temperature range to maintain structural integrity.

-

Mechanical Requirements:

- Strength: Choose a material with sufficient mechanical strength to withstand the expected physical stresses and handling during assembly and operation.

- Flexibility: If your application requires bending or flexing of the PCB, select a flexible material with appropriate flexibility and durability.

-

Dimensional stability: Consider the material’s dimensional stability to ensure accurate and consistent PCB fabrication.

-

Environmental Conditions:

- Moisture resistance: Select a material with low moisture absorption to prevent dimensional changes and degradation of electrical properties in humid environments.

- Chemical resistance: Ensure the material is resistant to the chemicals and solvents used in your manufacturing process and end-use environment.

-

Temperature range: Choose a material that can withstand the expected temperature range, considering both operating and storage conditions.

-

Manufacturing Process:

- Compatibility: Verify that the selected material is compatible with your manufacturing processes, such as soldering, drilling, and plating.

- Availability: Ensure the material is readily available from suppliers in the required thickness, copper weight, and panel size.

-

Lead time: Consider the lead time for procuring the material to avoid delays in your project timeline.

-

Cost:

- Material cost: Evaluate the cost of the material in relation to your project’s budget and performance requirements.

- Manufacturing cost: Consider the impact of the material choice on manufacturing costs, such as processing time, tooling, and yield.

- Total cost of ownership: Assess the long-term cost implications, including durability, reliability, and maintenance requirements.

Material Selection Flowchart

To assist in the PCB material selection process, here’s a simplified flowchart:

graph TD

A[Start] --> B{High-frequency application?}

B -->|Yes| C{Flexible PCB?}

B -->|No| D{High-power application?}

C -->|Yes| E[Use high-frequency flexible materials]

C -->|No| F[Use high-frequency rigid materials]

D -->|Yes| G{Efficient heat dissipation required?}

D -->|No| H{High-temperature application?}

G -->|Yes| I[Use metal core PCB materials]

G -->|No| J[Use FR-4 or other standard materials]

H -->|Yes| K[Use ceramic PCB materials]

H -->|No| L[Use FR-4 or other standard materials]

E --> M[End]

F --> M

I --> M

J --> M

K --> M

L --> M

PCB Material Comparison Table

To provide a quick reference for comparing the properties of common PCB materials, here’s a table summarizing their key characteristics:

| Material | Dielectric Constant | Loss Tangent | Thermal Conductivity (W/mK) | CTE (ppm/°C) | Typical Applications |

|---|---|---|---|---|---|

| FR-4 | 4.2-4.6 @ 1 MHz | 0.02 @ 1 MHz | 0.3-0.4 | 14-16 | General-purpose, consumer electronics |

| High-Frequency | 2.5-3.5 @ 10 GHz | 0.002-0.005 | 0.5-0.7 | 10-20 | RF, microwave, high-speed digital |

| Flexible | 3.2-3.5 @ 1 MHz | 0.002-0.004 | 0.2-0.3 | 20-30 | Wearables, mobile devices, medical |

| Metal Core | 3.5-4.5 @ 1 MHz | 0.01-0.02 | 1-3 | 6-10 | High-power LEDs, power electronics |

| Ceramic (Al2O3) | 9-10 @ 1 MHz | 0.0001-0.0003 | 20-30 | 6-8 | High-temperature, aerospace, military |

| Ceramic (AlN) | 8-9 @ 1 MHz | 0.0001-0.0003 | 150-180 | 4-5 | High-temperature, high-power electronics |

Frequently Asked Questions (FAQ)

- What is the most commonly used PCB material?

-

FR-4 is the most widely used PCB material due to its good balance of electrical, mechanical, and thermal properties, as well as its cost-effectiveness.

-

What PCB materials are suitable for high-frequency applications?

-

For high-frequency applications, materials with low dielectric constant and low loss tangent are preferred, such as Rogers RO4000 series, Isola IS680, and Taconic TLX.

-

Can flexible PCB materials be used for high-frequency applications?

-

Yes, there are specialized flexible PCB materials designed for high-frequency applications, such as DuPont Pyralux and 3M Flexible Circuits.

-

What are the advantages of using metal core PCB materials?

-

Metal core PCB materials offer excellent thermal conductivity, allowing for efficient heat dissipation in high-power applications like LED lighting and power electronics.

-

When should I consider using ceramic PCB materials?

- Ceramic PCB materials are ideal for high-temperature and high-reliability applications, such as aerospace, military, and medical devices, due to their excellent thermal stability and low dielectric loss.

Conclusion

Choosing the right PCB material is crucial for ensuring the performance, reliability, and longevity of your electronic devices. By understanding the properties and characteristics of different PCB materials and considering the specific requirements of your application, you can make informed decisions and select the most suitable material for your project.

Remember to evaluate the electrical, thermal, mechanical, and environmental requirements, as well as the manufacturing process and cost implications when selecting PCB materials. Consult the PCB material comparison table and the material selection flowchart provided in this guide to assist you in the decision-making process.

By selecting the appropriate PCB material, you can optimize signal integrity, thermal management, and structural integrity, ultimately leading to successful and reliable electronic products.

References

- IPC-4101: Specification for Base Materials for Rigid and Multilayer Printed Boards. IPC, 2019.

- IPC-4204: Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry. IPC, 2017.

- IPC-4562: Metal Foil for Printed Board Applications. IPC, 2018.

- Coombs, C. F. (Ed.). (2016

No responses yet