What are Aluminum PCBs?

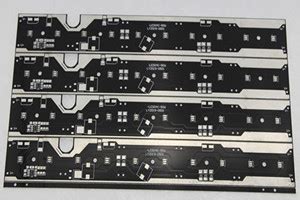

Aluminum PCBs, also known as Metal Core PCBs (MCPCBs), are printed circuit boards that feature an aluminum substrate instead of the traditional FR-4 material. The aluminum core provides excellent thermal conductivity, allowing for efficient heat dissipation from electronic components. This makes aluminum PCBs ideal for applications that generate significant amounts of heat, such as high-power LED lighting, automotive electronics, and power electronics.

Key Features of Aluminum PCBs

- Excellent thermal conductivity

- Improved reliability and longevity of electronic components

- Lightweight and durable

- Cost-effective solution for heat management

Advantages of Aluminum PCBs

1. Superior Heat Dissipation

The primary advantage of aluminum PCBs is their ability to efficiently dissipate heat generated by electronic components. The aluminum substrate has a high thermal conductivity, which allows heat to be quickly transferred away from the components and into the surrounding environment. This helps to maintain optimal operating temperatures, preventing overheating and ensuring the longevity of the electronic devices.

| Material | Thermal Conductivity (W/mK) |

|---|---|

| Aluminum | 205 |

| Copper | 385 |

| FR-4 | 0.3 |

As shown in the table above, aluminum has a significantly higher thermal conductivity compared to traditional FR-4 material, making it an excellent choice for applications that require efficient heat dissipation.

2. Improved Reliability and Durability

By effectively managing heat, aluminum PCBs help to improve the reliability and durability of electronic components. Overheating is a common cause of component failure, as it can lead to thermal stress, material degradation, and reduced performance. By keeping components within their optimal temperature range, aluminum PCBs minimize the risk of heat-related failures and extend the lifespan of electronic devices.

3. Lightweight and Compact Design

Aluminum PCBs are lightweight and can be designed with a compact form factor, making them suitable for applications where space and weight are critical factors. The aluminum substrate is thinner than traditional FR-4 material, allowing for the creation of slimmer and more compact electronic devices. This is particularly beneficial in industries such as automotive, aerospace, and portable electronics, where size and weight reduction are essential.

4. Cost-Effective Heat Management Solution

Implementing aluminum PCBs can be a cost-effective solution for managing heat in electronic devices. While the initial cost of aluminum PCBs may be higher than traditional FR-4 boards, the improved thermal management can lead to long-term cost savings. By reducing the need for additional heat sinks, cooling fans, or other thermal management components, aluminum PCBs can simplify the overall design and reduce manufacturing costs.

Applications of Aluminum PCBs

Aluminum PCBs find applications in various industries and domains where efficient heat dissipation is crucial. Some common applications include:

- High-power LED lighting

- Automotive electronics

- Power electronics and converters

- Motor drives and controllers

- Telecommunications equipment

- Industrial automation and control systems

- Aerospace and defense electronics

- Medical devices and equipment

Designing Aluminum PCBs

When designing aluminum PCBs, several factors need to be considered to ensure optimal performance and reliability. Some key design considerations include:

1. Thermal Management

Proper thermal management is essential when designing aluminum PCBs. This involves carefully selecting the appropriate aluminum substrate thickness, copper layer thickness, and thermal vias to efficiently transfer heat from the components to the aluminum core. Thermal simulations and analysis can help optimize the design for maximum heat dissipation.

2. Dielectric Material Selection

The choice of dielectric material is critical in aluminum PCB design. The dielectric layer must provide adequate electrical insulation while also facilitating efficient heat transfer. Common dielectric materials used in aluminum PCBs include:

- Thermal clad: A thermally conductive dielectric material that offers good electrical insulation and heat transfer properties.

- Aluminum oxide: A ceramic material with excellent thermal conductivity and electrical insulation properties.

- Epoxy-based dielectrics: Specially formulated epoxy materials that provide a balance between thermal conductivity and electrical insulation.

3. Component Placement and Routing

Component placement and routing play a crucial role in the performance of aluminum PCBs. Components that generate significant heat should be strategically placed to maximize heat dissipation through the aluminum substrate. Proper routing of power and signal traces is also essential to minimize electrical interference and ensure optimal signal integrity.

4. Manufacturing Considerations

Manufacturing aluminum PCBs requires specialized processes and equipment compared to traditional FR-4 PCBs. The aluminum substrate must be properly prepared and treated to ensure good adhesion of the dielectric layer and copper traces. Special attention must also be given to drilling, plating, and soldering processes to ensure the reliability and integrity of the final product.

RAYPCB’s Aluminum PCB Solutions

RAYPCB is a leading manufacturer of high-quality aluminum PCBs, offering a wide range of solutions for various industries and applications. With state-of-the-art facilities and a team of experienced engineers, RAYPCB provides customized aluminum PCB design and manufacturing services to meet the specific requirements of their clients.

RAYPCB’s Aluminum PCB Features

- Customizable aluminum substrate thickness and copper layer thickness

- Various dielectric material options to suit different applications

- Advanced thermal simulation and analysis for optimal heat dissipation

- Strict quality control and testing procedures to ensure reliability

- Quick turnaround times and competitive pricing

Frequently Asked Questions (FAQ)

1. What is the difference between aluminum PCBs and traditional FR-4 PCBs?

Aluminum PCBs feature an aluminum substrate instead of the traditional FR-4 material, providing superior thermal conductivity and heat dissipation properties. This makes aluminum PCBs ideal for applications that generate significant amounts of heat, while FR-4 PCBs are better suited for general-purpose electronic applications.

2. Can aluminum PCBs be used in high-frequency applications?

Yes, aluminum PCBs can be used in high-frequency applications. However, special considerations must be made during the design process to ensure optimal signal integrity and minimize electrical interference. This may involve using specific dielectric materials, designing appropriate ground planes, and implementing proper shielding techniques.

3. How do I select the right aluminum PCB manufacturer?

When selecting an aluminum PCB manufacturer, consider factors such as their experience, manufacturing capabilities, quality control processes, and customer support. Look for manufacturers that offer customizable solutions, have a proven track record of delivering high-quality products, and provide comprehensive technical support throughout the design and manufacturing process.

4. What are the common challenges in aluminum PCB manufacturing?

Some common challenges in aluminum PCB manufacturing include ensuring proper adhesion between the aluminum substrate and the dielectric layer, managing thermal stresses during the manufacturing process, and achieving consistent plating and soldering results. Experienced manufacturers like RAYPCB have developed specialized processes and techniques to overcome these challenges and deliver reliable aluminum PCBs.

5. How can I optimize my aluminum PCB design for better heat dissipation?

To optimize your aluminum PCB design for better heat dissipation, consider the following factors:

- Select an appropriate aluminum substrate thickness and copper layer thickness based on your application’s thermal requirements.

- Use thermal vias to create efficient heat transfer paths from the components to the aluminum core.

- Strategically place heat-generating components to maximize heat spreading through the aluminum substrate.

- Choose a suitable dielectric material that offers a balance between thermal conductivity and electrical insulation.

- Conduct thorough thermal simulations and analysis to validate and optimize your design before manufacturing.

Conclusion

Aluminum PCBs offer a superior solution for managing heat in electronic devices, providing excellent thermal conductivity, improved reliability, and compact design possibilities. By understanding the advantages, applications, and design considerations of aluminum PCBs, engineers and designers can create more efficient and reliable electronic products.

RAYPCB, with its expertise in aluminum PCB manufacturing, is well-positioned to support customers in various industries, offering customizable solutions and high-quality products. By partnering with RAYPCB, companies can leverage the benefits of aluminum PCBs to drive innovation and success in their respective markets.

No responses yet