PCB Material Selection

The choice of PCB material is crucial as it directly affects the board’s electrical, thermal, and mechanical properties. The most common PCB materials include:

-

FR-4: A glass-reinforced epoxy laminate, FR-4 is the most widely used PCB material due to its excellent electrical insulation properties, mechanical strength, and cost-effectiveness.

-

High-Frequency Materials: For applications involving high frequencies, such as RF and microwave circuits, materials like Rogers RO4000 series, Teflon, and ceramic-based laminates are used for their superior dielectric properties and low loss tangents.

-

Metal Core PCBs: Used in high-power applications that require efficient heat dissipation, metal core PCBs feature a metal substrate (usually aluminum) to enhance thermal conductivity.

Dielectric Constant and Loss Tangent

Two essential properties of PCB materials are the dielectric constant (Dk) and loss tangent (Df). The dielectric constant represents the material’s ability to store electrical energy, while the loss tangent indicates the material’s dissipation of electrical energy as heat. Lower dielectric constants and loss tangents are preferred for high-frequency applications to minimize signal loss and distortion.

| Material | Dielectric Constant (Dk) | Loss Tangent (Df) |

|---|---|---|

| FR-4 | 4.35 @ 1 MHz | 0.02 @ 1 MHz |

| Rogers RO4350B | 3.48 @ 10 GHz | 0.0037 @ 10 GHz |

| Teflon | 2.1 @ 1 MHz | 0.0002 @ 1 MHz |

PCB Thickness

PCB thickness is another crucial parameter that affects the board’s mechanical strength, signal integrity, and thermal management. Standard PCB thicknesses range from 0.8mm to 1.6mm, with thinner boards being more flexible and cost-effective, while thicker boards offer better mechanical stability and heat dissipation.

Copper Thickness

The thickness of the copper traces on a PCB is typically measured in ounces per square foot (oz/ft²). Common copper thicknesses include:

- 0.5 oz/ft² (17.5 μm)

- 1 oz/ft² (35 μm)

- 2 oz/ft² (70 μm)

- 3 oz/ft² (105 μm)

Thicker copper traces have lower resistance and can carry higher currents, but they also increase the board’s weight and cost.

PCB Layer Stack-up

The number and arrangement of layers in a PCB, known as the layer stack-up, play a vital role in signal integrity, EMI/EMC performance, and manufacturability. Some common layer stack-ups include:

-

Single-layer: Used for simple, low-cost projects with minimal component count and routing complexity.

-

Double-layer: Offers better signal routing and ground plane options compared to single-layer boards.

-

Four-layer: Provides dedicated power and ground planes, making it suitable for more complex designs with higher component density and improved signal integrity.

-

Six-layer and above: Used for advanced, high-speed designs that require multiple power and ground planes, as well as additional signal layers for dense routing.

Via Types

Vias are conductive holes that connect different layers of a PCB. There are several types of vias, each with its own advantages and limitations:

- Through-hole vias: Extend through the entire thickness of the board, offering strong mechanical connections but consuming more space.

- Blind vias: Connect an outer layer to an inner layer, providing more design flexibility and reducing board size.

- Buried vias: Connect inner layers without reaching the outer layers, enabling higher component density and improved signal integrity.

- Micro vias: Laser-drilled vias with diameters less than 150 μm, used for high-density interconnect (HDI) designs.

PCB Trace Width and Spacing

The width and spacing of PCB traces directly impact signal integrity, current-carrying capacity, and manufacturability. Factors that influence trace width and spacing include:

-

Signal type: High-speed signals require wider traces and greater spacing to minimize crosstalk and maintain signal integrity.

-

Current-carrying capacity: Traces carrying higher currents need to be wider to prevent excessive heating and ensure reliable operation.

-

Manufacturing constraints: Minimum trace width and spacing are limited by the PCB manufacturer’s capabilities and the chosen fabrication technology.

Trace Width Calculation

To calculate the minimum trace width required for a given current, you can use the following formula:

W = (I / (k * ΔT^b))^(1/c)

Where:

– W = Trace width (mils)

– I = Current (amps)

– ΔT = Temperature rise above ambient (°C)

– k, b, c = Constants depending on the copper thickness and temperature rise

For example, a 1 oz/ft² copper trace carrying 1A with a 10°C temperature rise would require a minimum width of:

W = (1 / (0.048 * 10^0.44))^(1/0.725) = 20.6 mils

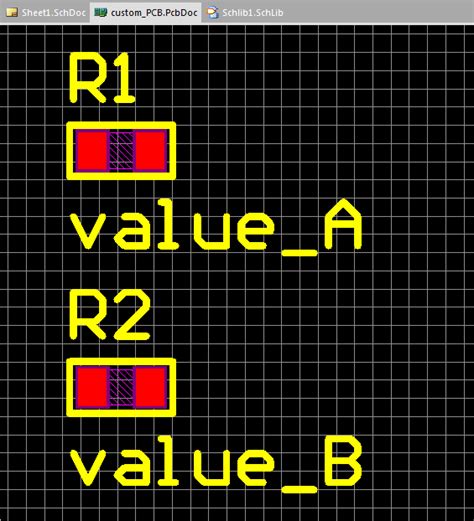

PCB Footprint Design

PCB footprints, also known as land patterns, are the arrangement of pads and holes on a PCB that correspond to the pins or leads of a component. Proper footprint design ensures reliable soldering, mechanical stability, and compliance with component manufacturer recommendations.

Surface Mount (SMT) Footprints

Surface mount footprints are designed for components that are soldered directly onto the surface of the PCB. Common SMT footprints include:

- Quad Flat Pack (QFP)

- Ball Grid Array (BGA)

- Small Outline Package (SOP)

- Chip Scale Package (CSP)

When designing SMT footprints, consider the following:

-

Pad size and shape: Ensure pads are large enough for reliable soldering but not so large that they introduce unwanted capacitance or limit routing space.

-

Solder mask opening: Provide adequate solder mask opening around pads to prevent solder bridging and improve manufacturability.

-

Courtyard and keepout areas: Define component courtyard and keepout areas to ensure proper placement and avoid conflicts with other components or features.

Through-Hole (THT) Footprints

Through-hole footprints are designed for components with leads that pass through holes in the PCB and are soldered on the opposite side. When designing THT footprints, consider:

-

Hole size: Ensure holes are large enough for component leads to pass through easily but not so large that they weaken the PCB or introduce unwanted capacitance.

-

Pad size and shape: Provide sufficient pad area for reliable soldering and mechanical stability.

-

Lead spacing: Maintain appropriate lead spacing to prevent shorts and facilitate manual soldering if required.

PCB Design Rules and Constraints

To ensure manufacturability and reliability, PCB designs must adhere to a set of design rules and constraints. These rules are determined by the PCB manufacturer and the specific fabrication technology being used. Some common design rules include:

-

Minimum trace width and spacing: Dictates the smallest allowable trace width and the minimum spacing between traces and other features.

-

Minimum drill size: Specifies the smallest hole diameter that can be reliably drilled in the PCB.

-

Minimum annular ring: Defines the minimum amount of copper that must surround a hole to ensure reliable connections and prevent breakouts.

-

Solder mask and silkscreen clearance: Specifies the minimum distance between solder mask openings, silkscreen features, and other elements to prevent manufacturing issues.

Design for Manufacturing (DFM)

Design for Manufacturing (DFM) is a set of guidelines and best practices that help optimize PCB designs for manufacturability, reliability, and cost-effectiveness. Some key DFM considerations include:

-

Avoiding acute angles in traces: Use 45° angles or curves instead of 90° angles to improve manufacturability and signal integrity.

-

Providing sufficient clearance: Ensure adequate clearance between components, traces, and board edges to facilitate assembly and prevent short circuits.

-

Using standard hole sizes: Stick to standard drill sizes whenever possible to reduce tooling costs and improve manufacturing efficiency.

-

Minimizing the number of unique parts: Use common components and footprints to reduce inventory costs and simplify assembly.

FAQ

- What is the most common PCB material, and why is it so widely used?

-

FR-4 is the most common PCB material due to its excellent electrical insulation properties, mechanical strength, and cost-effectiveness. It is a glass-reinforced epoxy laminate that offers a good balance of performance and affordability for a wide range of applications.

-

How do I choose the right copper thickness for my PCB design?

-

The choice of copper thickness depends on the current-carrying requirements of your design. Thicker copper traces have lower resistance and can carry higher currents, but they also increase the board’s weight and cost. A good starting point is 1 oz/ft² (35 μm) for most general-purpose designs, while high-current applications may require 2 oz/ft² (70 μm) or thicker traces.

-

What are the advantages of using a four-layer PCB over a double-layer board?

-

Four-layer PCBs offer several advantages over double-layer boards, including dedicated power and ground planes, improved signal integrity, and better EMI/EMC performance. The additional layers also provide more routing space, allowing for higher component density and more complex designs.

-

How can I ensure my PCB design is manufacturable?

-

To ensure your PCB design is manufacturable, follow the design rules and constraints provided by your PCB manufacturer, and adhere to Design for Manufacturing (DFM) best practices. This includes using standard hole sizes, providing sufficient clearance between features, avoiding acute angles in traces, and minimizing the number of unique parts in your design.

-

What are the differences between surface mount (SMT) and through-hole (THT) components, and how do they affect PCB design?

- Surface mount (SMT) components are soldered directly onto the surface of the PCB, while through-hole (THT) components have leads that pass through holes in the board and are soldered on the opposite side. SMT components are generally smaller and more suitable for high-density designs, while THT components offer stronger mechanical connections and are easier to solder manually. When designing a PCB, you must consider the specific requirements of each component type, such as pad size, shape, and spacing, to ensure proper functionality and manufacturability.

By understanding and carefully considering these basic PCB Parameters, designers can create more robust, reliable, and manufacturable PCBs that meet the specific requirements of their applications. As technology advances and new materials and manufacturing techniques emerge, staying up-to-date with the latest design guidelines and best practices will be essential for success in the ever-evolving world of PCB design and fabrication.

No responses yet