What is Flex PCB?

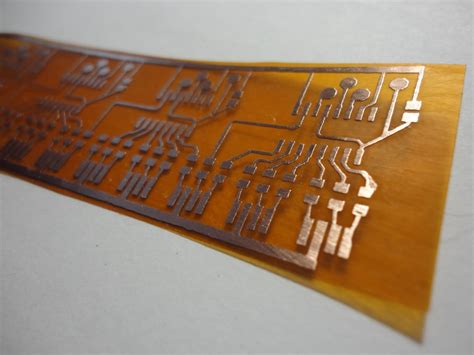

Flexible printed circuit boards (Flex PCBs) are a type of printed circuit board that consists of a thin, flexible plastic substrate with conductive traces and components mounted on it. Unlike traditional rigid PCBs, Flex PCBs can bend, twist, and fold without damaging the electrical connections, making them ideal for applications where space is limited or where the PCB needs to conform to a specific shape.

Flex PCBs are made from a variety of materials, including polyimide, polyester, and PEEK (polyetheretherketone). These materials are chosen for their flexibility, durability, and ability to withstand high temperatures and harsh environments. The conductive traces on a Flex PCB are typically made from copper, which is bonded to the substrate using an adhesive.

Advantages of Flex PCBs

Flex PCBs offer several advantages over traditional rigid PCBs:

-

Flexibility: Flex PCBs can bend and fold without damaging the electrical connections, making them ideal for applications where space is limited or where the PCB needs to conform to a specific shape.

-

Durability: Flex PCBs are more durable than rigid PCBs because they can withstand repeated bending and flexing without breaking or cracking.

-

Lightweight: Flex PCBs are typically thinner and lighter than rigid PCBs, making them ideal for applications where weight is a concern.

-

Reduced assembly costs: Flex PCBs can reduce assembly costs by eliminating the need for connectors and cables between different parts of the assembly.

Applications of Flex PCBs

Flex PCBs are used in a wide range of applications, including:

-

Medical devices: Flex PCBs are often used in medical devices such as pacemakers, hearing aids, and insulin pumps where space is limited and the PCB needs to conform to the shape of the device.

-

Automotive electronics: Flex PCBs are used in automotive applications such as dashboards, entertainment systems, and sensors where the PCB needs to fit into tight spaces and withstand harsh environments.

-

Wearable electronics: Flex PCBs are used in wearable electronics such as smartwatches, fitness trackers, and virtual reality headsets where the PCB needs to be lightweight and flexible.

-

Aerospace and defense: Flex PCBs are used in aerospace and defense applications such as satellites, missiles, and aircraft where the PCB needs to withstand extreme temperatures and vibrations.

Flex PCB Manufacturing Process

The manufacturing process for Flex PCBs is similar to that of rigid PCBs, but with a few key differences:

-

Substrate preparation: The flexible substrate is cleaned and treated to improve adhesion of the copper traces.

-

Copper lamination: A thin layer of copper is laminated onto the substrate using heat and pressure.

-

Photolithography: The desired circuit pattern is transferred onto the copper layer using photolithography.

-

Etching: The unwanted copper is removed using a chemical etching process, leaving only the desired circuit pattern.

-

Coverlay application: A protective coverlay is applied over the circuit pattern to protect it from damage.

-

Component assembly: The electronic components are attached to the Flex PCB using solder paste and reflow soldering.

-

Testing: The Flex PCB is tested to ensure that it meets the required specifications and functions as intended.

Challenges in Flex PCB Manufacturing

Flex PCB manufacturing presents several challenges compared to rigid PCB manufacturing:

-

Material selection: Choosing the right material for the substrate and coverlay is critical to ensuring the flexibility and durability of the Flex PCB.

-

Adhesion: Ensuring good adhesion between the copper traces and the substrate can be challenging, especially in applications where the Flex PCB will be subjected to repeated bending and flexing.

-

Coverlay application: Applying the coverlay evenly and without wrinkles or air bubbles can be difficult, especially on complex shapes and contours.

-

Component assembly: Attaching components to a flexible substrate can be more challenging than on a rigid substrate, as the components can shift or become damaged during the reflow soldering process.

Choosing a Flex PCB Manufacturer

When choosing a Flex PCB manufacturer, there are several factors to consider:

-

Experience: Look for a manufacturer with experience in producing Flex PCBs for your specific application.

-

Quality: Choose a manufacturer with a proven track record of producing high-quality Flex PCBs that meet or exceed industry standards.

-

Capabilities: Make sure the manufacturer has the equipment and expertise to produce Flex PCBs with the features and specifications you require.

-

Turnaround time: Consider the manufacturer’s lead time and ability to meet your production schedule.

-

Customer service: Look for a manufacturer with responsive and knowledgeable customer service that can answer your questions and provide support throughout the manufacturing process.

Top Flex PCB Manufacturers

Here are some of the top Flex PCB manufacturers in the industry:

| Manufacturer | Location | Specialties |

|---|---|---|

| Flexium Interconnect | Switzerland | Medical, automotive, industrial |

| Printed Circuits | USA | Medical, aerospace, defense |

| Cicor Group | Switzerland | Medical, industrial, aerospace |

| Würth Elektronik | Germany | Automotive, industrial, medical |

| TTM Technologies | USA | Aerospace, defense, medical |

Flex PCB Design Considerations

When designing a Flex PCB, there are several key considerations to keep in mind:

-

Bend radius: The minimum bend radius of the Flex PCB will depend on the thickness and material of the substrate and coverlay. It’s important to design the PCB with the appropriate bend radius to avoid damaging the traces or components.

-

Copper thickness: The thickness of the copper traces will affect the flexibility and current-carrying capacity of the Flex PCB. Thinner traces are more flexible but have lower current-carrying capacity, while thicker traces are less flexible but can carry more current.

-

Component placement: Components should be placed in areas of the Flex PCB that will not be subject to repeated bending or flexing. It’s also important to consider the orientation of the components to minimize stress on the solder joints.

-

Stiffeners: Stiffeners can be added to areas of the Flex PCB that require additional support or rigidity, such as connector areas or component mounting areas.

-

Shielding: In applications where the Flex PCB will be exposed to electromagnetic interference (EMI), it may be necessary to add shielding to the PCB to protect it from interference.

FAQ

-

What is the difference between a Flex PCB and a rigid PCB?

A Flex PCB is a type of printed circuit board that is flexible and can bend and fold without damaging the electrical connections. A rigid PCB, on the other hand, is a traditional PCB that is made from a rigid material and cannot bend or flex. -

What are the advantages of using a Flex PCB?

Flex PCBs offer several advantages over rigid PCBs, including flexibility, durability, reduced weight, and reduced assembly costs. They are ideal for applications where space is limited or where the PCB needs to conform to a specific shape. -

What materials are used to make Flex PCBs?

Flex PCBs are typically made from flexible plastic substrates such as polyimide, polyester, or PEEK. The conductive traces are usually made from copper, which is bonded to the substrate using an adhesive. -

What are some common applications for Flex PCBs?

Flex PCBs are used in a wide range of applications, including medical devices, automotive electronics, wearable electronics, and aerospace and defense applications. -

What should I consider when choosing a Flex PCB manufacturer?

When choosing a Flex PCB manufacturer, consider factors such as experience, quality, capabilities, turnaround time, and customer service. Look for a manufacturer with a proven track record of producing high-quality Flex PCBs for your specific application.

Conclusion

Flex PCBs are a valuable and useful technology that offer several advantages over traditional rigid PCBs, including flexibility, durability, and reduced weight and assembly costs. They are used in a wide range of applications, from medical devices to aerospace and defense.

When designing a Flex PCB, it’s important to consider factors such as bend radius, copper thickness, component placement, stiffeners, and shielding. Choosing the right materials and manufacturing process is also critical to ensuring the quality and reliability of the finished product.

If you’re considering using Flex PCBs in your next project, be sure to choose a reputable and experienced manufacturer that can provide the expertise and support you need to bring your design to life.

No responses yet