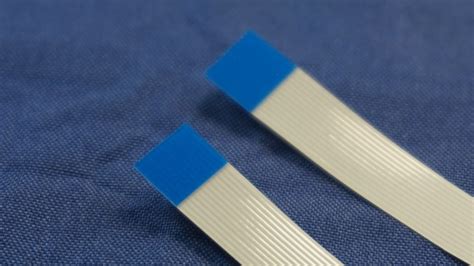

What is Flexible Flat Cable?

Flexible Flat Cable, also known as FFC, is a type of cable that consists of multiple conductors that are arranged in a flat, parallel configuration. These conductors are typically made of copper or tinned copper and are insulated with a thin layer of plastic, such as polyester or polyimide. The insulation is then laminated together to form a flat, ribbon-like cable.

FFCs are designed to be flexible, allowing them to bend and twist without damaging the conductors or the insulation. This flexibility makes them ideal for use in applications where space is limited or where the cable needs to move or flex repeatedly.

Types of Flexible Flat Cables

There are several types of Flexible Flat Cables available, each with its own unique characteristics and applications. Some of the most common types include:

- Type 1: This type of FFC has a single layer of conductors and is typically used for low-speed, low-power applications.

- Type 2: Type 2 FFCs have two layers of conductors, with a ground plane between them. This design provides better signal integrity and EMI shielding than Type 1 cables.

- Type 3: This type of FFC has three layers of conductors, with ground planes between each layer. It offers even better signal integrity and EMI shielding than Type 2 cables.

- Shielded FFC: Shielded FFCs have an additional layer of conductive material that surrounds the conductors, providing enhanced EMI shielding.

- High-Speed FFC: These FFCs are designed for high-speed data transmission applications and feature specialized materials and designs to minimize signal loss and distortion.

| Type | Layers | Ground Plane | Applications |

|---|---|---|---|

| Type 1 | 1 | No | Low-speed, low-power |

| Type 2 | 2 | Yes | Improved signal integrity and EMI shielding |

| Type 3 | 3 | Yes | Enhanced signal integrity and EMI shielding |

| Shielded FFC | 1-3 | Yes | Enhanced EMI shielding |

| High-Speed FFC | 1-3 | Yes | High-speed data transmission |

Advantages of Flexible Flat Cable

Flexible Flat Cables offer several advantages over traditional round cables, making them an attractive choice for many applications. Some of the key advantages include:

Space Savings

One of the primary advantages of FFCs is their ability to save space. Because they are thin and flat, they can be routed through tight spaces and around obstacles more easily than round cables. This is particularly important in applications where space is at a premium, such as in mobile devices, laptops, and other compact electronic devices.

Flexibility

As the name suggests, Flexible Flat Cables are designed to be flexible. They can bend and twist without damaging the conductors or the insulation, making them ideal for use in applications where the cable needs to move or flex repeatedly. This flexibility also makes them easier to install and route than rigid cables.

Lightweight

FFCs are typically much lighter than round cables of equivalent size and performance. This is due to their thin, flat design and the use of lightweight materials such as polyester and polyimide for insulation. The reduced weight can be a significant advantage in applications where every gram counts, such as in aerospace and portable devices.

Reliability

Flexible Flat Cables are designed to provide reliable connections, even in harsh environments. The flat, parallel configuration of the conductors minimizes crosstalk and signal interference, while the laminated insulation provides excellent protection against moisture, dust, and other contaminants. Many FFCs are also rated for high temperatures and can withstand exposure to chemicals and solvents.

Cost-Effective

Despite their many advantages, Flexible Flat Cables are often more cost-effective than equivalent round cables. This is due to their simple construction and the use of relatively inexpensive materials. The ease of installation and routing can also help reduce labor costs in many applications.

Applications of Flexible Flat Cable

Flexible Flat Cables are used in a wide range of applications, from consumer electronics to industrial equipment. Some of the most common applications include:

Consumer Electronics

FFCs are widely used in consumer electronics, such as smartphones, tablets, laptops, and digital cameras. They are often used to connect displays, keyboards, touchpads, and other components, thanks to their ability to save space and provide reliable connections.

Automotive Electronics

In the automotive industry, FFCs are used to connect various electronic components, such as sensors, displays, and control modules. They are particularly well-suited to this application due to their flexibility, reliability, and resistance to vibration and temperature extremes.

Medical Devices

Flexible Flat Cables are also used in medical devices, such as patient monitors, imaging equipment, and surgical instruments. Their lightweight, compact design and reliability make them ideal for use in these critical applications.

Industrial Equipment

FFCs are used in a variety of industrial equipment, such as robots, machine tools, and automation systems. Their flexibility and resistance to harsh environments make them well-suited to these applications, where reliability and durability are key concerns.

Aerospace and Military

In the aerospace and military sectors, FFCs are used in a range of applications, from avionics to satellite systems. Their lightweight design and reliability make them ideal for use in these demanding environments, where every gram and every connection counts.

Designing with Flexible Flat Cable

When designing with Flexible Flat Cable, there are several key factors to consider to ensure optimal performance and reliability. These include:

Cable Selection

Choosing the right type of FFC for your application is critical. Consider factors such as the number of conductors required, the signal speed and integrity needed, the level of EMI shielding required, and the environmental conditions the cable will be exposed to.

Connector Selection

Selecting the appropriate connectors for your FFC is also important. There are many types of FFC connectors available, each with its own advantages and limitations. Consider factors such as the number of contacts required, the pitch (spacing) of the contacts, the mounting style (surface mount or through-hole), and the level of durability and reliability needed.

Routing and Installation

Proper routing and installation of FFCs is essential for optimal performance and reliability. When routing FFCs, avoid sharp bends or twists that could damage the conductors or insulation. Use appropriate strain relief methods to prevent damage due to flexing or pulling. If the cable will be exposed to harsh environments, consider using additional protection such as conduits or sheaths.

Testing and Validation

Before putting your FFC design into production, it is important to thoroughly test and validate its performance. This may include electrical testing to ensure signal integrity and reliability, as well as environmental testing to ensure the cable can withstand the expected operating conditions. Failure mode and effects analysis (FMEA) can also be useful to identify potential failure modes and develop mitigation strategies.

Innovative Applications of Flexible Flat Cable

Flexible Flat Cables are enabling a wide range of innovative applications across various industries. Some examples include:

Wearable Technology

FFCs are playing a key role in the development of wearable technology, such as smartwatches, fitness trackers, and medical monitoring devices. Their lightweight, flexible design allows these devices to be worn comfortably for extended periods, while providing reliable connections between components.

Robotics

In the field of robotics, FFCs are enabling the development of more flexible and agile robots. By using FFCs to connect sensors, actuators, and control modules, robots can be designed with greater freedom of movement and improved dexterity.

Flexible Electronics

Flexible Flat Cables are also enabling the development of flexible electronics, such as flexible displays, solar cells, and sensors. By providing reliable connections between components in a flexible form factor, FFCs are helping to unlock new possibilities in this exciting field.

Smart Textiles

FFCs are also being used in the development of smart textiles, which integrate electronic components into fabrics for applications such as health monitoring, communication, and entertainment. The flexibility and durability of FFCs make them well-suited to this application, where the cables must be able to withstand repeated bending and stretching.

Frequently Asked Questions

-

What is the difference between Flexible Flat Cable and Flexible Printed Circuit?

Flexible Flat Cable (FFC) and Flexible Printed Circuit (FPC) are similar in that they both provide flexible, flat connections between electronic components. However, there are some key differences. FFCs consist of multiple conductors that are laminated together with insulation, while FPCs have conductors that are printed or etched onto a flexible substrate. FFCs are typically used for simpler, lower-density connections, while FPCs are used for more complex, higher-density connections. -

Can Flexible Flat Cables be used for high-speed data transmission?

Yes, there are specialized Flexible Flat Cables designed for high-speed data transmission applications. These cables feature optimized conductor designs and materials to minimize signal loss and distortion, allowing for reliable high-speed data transfer. -

How do I terminate Flexible Flat Cables?

Flexible Flat Cables are typically terminated using specialized connectors that are designed to mate with the flat, ribbon-like cable. These connectors come in various styles, including Zero Insertion Force (ZIF), Low Insertion Force (LIF), and Non-ZIF. The choice of connector will depend on factors such as the number of conductors, the pitch of the cable, and the requirements of the application. -

What is the maximum length of Flexible Flat Cable that can be used?

The maximum length of Flexible Flat Cable that can be used depends on several factors, including the conductor size, the signal speed, and the level of signal integrity required. In general, longer cable lengths will result in greater signal loss and distortion, so it is important to carefully consider the requirements of your application when selecting cable length. Consult with your cable supplier or refer to the cable specifications for guidance on maximum recommended lengths. -

How do I choose the right Flexible Flat Cable for my application?

Choosing the right Flexible Flat Cable for your application involves considering several key factors, such as the number of conductors required, the signal speed and integrity needed, the level of EMI shielding required, and the environmental conditions the cable will be exposed to. It’s also important to consider the mechanical requirements, such as the degree of flexibility needed and the expected number of flexing cycles. Consulting with a knowledgeable cable supplier or reviewing the cable specifications can help guide your selection process.

Conclusion

Flexible Flat Cables are a versatile and innovative solution for providing reliable, space-saving connections in a wide range of electronic applications. Their thin, lightweight, and flexible design makes them ideal for use in compact devices, while their reliability and durability make them well-suited to harsh environments.

As technology continues to advance, FFCs are enabling new possibilities in fields such as wearable technology, robotics, flexible electronics, and smart textiles. By understanding the advantages and applications of Flexible Flat Cables, and by following best practices for design and installation, engineers and designers can unlock new levels of innovation and performance in their products.

Whether you’re designing consumer electronics, medical devices, industrial equipment, or aerospace systems, Flexible Flat Cables offer a powerful tool for making your designs more compact, reliable, and innovative. By staying up-to-date with the latest developments in FFC technology and working with knowledgeable suppliers and partners, you can harness the full potential of these remarkable cables to bring your ideas to life.

No responses yet