What is a Low-Voltage Cutoff Circuit?

A low-voltage cutoff circuit is an electronic circuit that monitors the voltage of a battery and disconnects the load when the voltage drops below a predetermined threshold. This prevents the battery from being drained beyond its safe operating limit, which can lead to permanent damage or reduced capacity.

LVC circuits are commonly found in portable electronic devices such as:

– Smartphones

– Laptops

– Wireless earbuds

– Portable speakers

– Remote-controlled toys

Why is a Low-Voltage Cutoff Circuit Important?

Batteries have a minimum voltage level below which they should not be discharged. Discharging a battery beyond this point can cause several issues:

-

Reduced battery life: Over-discharging a battery can cause irreversible chemical changes, leading to a permanent reduction in capacity.

-

Safety hazards: Some batteries, such as lithium-ion, can become unstable when over-discharged, potentially leading to fires or explosions.

-

Device malfunction: When the battery voltage drops too low, the device may not function properly or may shut down unexpectedly.

LVC circuits help prevent these issues by ensuring that the battery is never discharged below its safe operating voltage.

How Does a Low-Voltage Cutoff Circuit Work?

An LVC circuit constantly monitors the battery voltage and compares it to a predetermined threshold. When the voltage drops below this threshold, the circuit disconnects the load from the battery, preventing further discharge.

The key components of an LVC circuit are:

-

Voltage reference: This provides a stable and accurate reference voltage to which the battery voltage is compared.

-

Comparator: This compares the battery voltage to the reference voltage and outputs a high or low signal based on the result.

-

Switching element: This is typically a transistor or relay that disconnects the load from the battery when triggered by the comparator output.

-

Hysteresis: This is a small voltage difference between the turn-off and turn-on points, which prevents the circuit from rapidly switching on and off when the battery voltage is close to the threshold.

Here’s a simple block diagram illustrating the components of an LVC circuit:

| Component | Function |

|---|---|

| Battery | Provides power to the device and the LVC circuit |

| Voltage Reference | Provides a stable reference voltage for comparison |

| Comparator | Compares battery voltage to the reference voltage |

| Switching Element | Disconnects the load when triggered by the comparator |

| Load | The device or component powered by the battery |

Designing a Low-Voltage Cutoff Circuit

To design an LVC circuit, you need to consider several factors:

-

Battery chemistry: Different Battery Types have different safe discharge voltages. For example, a lithium-ion cell should not be discharged below 3.0V, while a lead-acid cell should not go below 1.75V per cell.

-

Load requirements: The LVC circuit must be able to handle the maximum current drawn by the load.

-

Hysteresis: The hysteresis voltage should be chosen to prevent rapid on/off switching while ensuring that the battery is not over-discharged.

-

Power consumption: The LVC circuit itself should consume minimal power to avoid draining the battery unnecessarily.

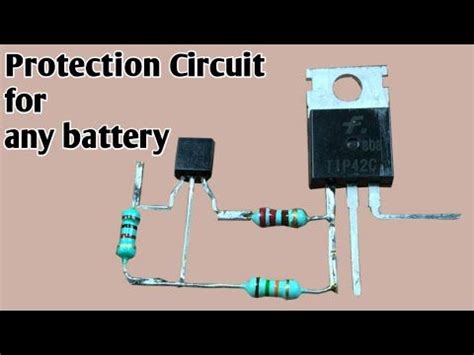

Here’s an example of a simple LVC circuit using a comparator and a MOSFET:

[Insert schematic diagram of the LVC circuit]

In this circuit:

– The voltage reference is provided by a zener diode (D1) and a resistor divider (R1 and R2).

– The comparator (U1) compares the battery voltage to the reference voltage.

– The MOSFET (Q1) acts as the switching element, disconnecting the load when the comparator output goes low.

– The resistor R3 and capacitor C1 provide hysteresis to prevent rapid switching.

Choosing Components for Your Low-Voltage Cutoff Circuit

When selecting components for your LVC circuit, consider the following:

-

Comparator: Choose a comparator with low quiescent current and a wide supply voltage range. Examples include the LM393 and MAX921.

-

Voltage reference: Use a zener diode or a dedicated voltage reference IC with low temperature drift and high accuracy. The LM4040 and LT1004 are popular choices.

-

Switching element: Select a MOSFET or transistor with low on-resistance and a current rating sufficient for your load. The IRF540N and 2N3904 are commonly used.

-

Resistors and capacitors: Use high-precision resistors (1% or better) for the Voltage Divider and hysteresis resistor. The hysteresis capacitor should be a low-leakage type, such as a film or ceramic capacitor.

Building and Testing Your Low-Voltage Cutoff Circuit

Once you have designed your circuit and chosen your components, follow these steps to build and test your LVC circuit:

-

Assemble the circuit on a breadboard or PCB, double-checking component values and orientations.

-

Connect a Variable Power Supply in place of the battery, set to the nominal battery voltage.

-

Connect a resistive load (such as a power resistor) to the output of the LVC circuit.

-

Slowly decrease the power supply voltage while monitoring the load voltage with a multimeter.

-

Verify that the load is disconnected when the input voltage reaches the designed cutoff threshold.

-

Slowly increase the power supply voltage and verify that the load is reconnected at the designed turn-on threshold (cutoff voltage + hysteresis).

-

Repeat steps 4-6 several times to ensure consistent operation.

Integrating the Low-Voltage Cutoff Circuit into Your Device

To integrate the LVC circuit into your battery-powered device:

-

Determine the best location for the LVC circuit, considering factors such as space constraints, heat dissipation, and proximity to the battery and load.

-

Design a PCB or use point-to-point wiring to connect the LVC circuit to the battery and load.

-

Ensure that the LVC circuit’s ground is connected to the device’s ground and that the switching element is rated for the maximum load current.

-

Test the device thoroughly to verify that the LVC circuit operates as intended and does not interfere with other functions.

Troubleshooting Common Issues

If your LVC circuit is not working as expected, consider these common issues:

-

Incorrect component values or orientations: Double-check the schematic and component placement.

-

Poor connections: Ensure that all connections are secure and free of corrosion.

-

Insufficient hysteresis: If the circuit rapidly switches on and off, increase the hysteresis by adjusting the resistor and capacitor values.

-

Incorrect cutoff voltage: Verify that the voltage reference and comparator are functioning correctly and that the cutoff voltage is set to the appropriate level for your battery chemistry.

Frequently Asked Questions (FAQ)

-

Can I use an LVC circuit with any battery type?

Yes, LVC circuits can be used with any battery type, but the cutoff voltage must be adjusted according to the specific battery chemistry. -

How do I determine the appropriate cutoff voltage for my battery?

Consult the battery manufacturer’s datasheet or application notes for the recommended minimum discharge voltage. For common battery types: - Lithium-ion: 3.0V per cell

- Lead-acid: 1.75V per cell

-

NiMH and NiCd: 1.0V per cell

-

Can I use an LVC circuit to protect my device from overcharging?

No, LVC circuits are designed to prevent over-discharging. To protect against overcharging, you need a separate overcharge protection circuit or a battery management system (BMS). -

Will an LVC circuit drain my battery when the device is not in use?

A well-designed LVC circuit should consume minimal power when the device is not in use. However, it will still contribute to some battery drain over extended periods. To minimize this, choose components with low quiescent current and consider adding a manual disconnect switch for long-term storage. -

Can I use an LVC circuit with a rechargeable battery?

Yes, LVC circuits can be used with rechargeable batteries. However, ensure that the cutoff voltage is set appropriately for the specific battery chemistry and that the charging circuit does not interfere with the LVC circuit’s operation.

Conclusion

Low-voltage cutoff circuits are essential for protecting batteries from over-discharging and ensuring the longevity and safety of battery-powered devices. By understanding the working principle behind LVC circuits and following the steps outlined in this article, you can design, build, and integrate an LVC circuit into your own projects.

Remember to choose components carefully, consider your specific battery chemistry and load requirements, and thoroughly test your circuit before deployment. With a well-designed LVC circuit, you can ensure that your battery-powered devices operate reliably and safely for years to come.

No responses yet