Introduction to PCB Plating Simulation

Printed Circuit Board (PCB) design is a complex process that involves multiple steps, from schematic capture to layout and routing. One critical aspect of PCB design is the plating process, which involves depositing a thin layer of metal on the copper traces to protect them from corrosion and improve their conductivity. However, the plating process can be challenging to predict and optimize, leading to potential issues such as uneven plating thickness, voids, and defects.

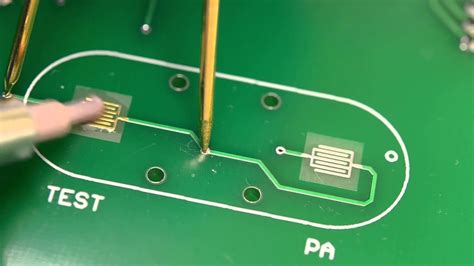

To address these challenges, we have developed a new tool for PCB designers: PCB Plating Simulation. This innovative software allows designers to simulate the plating process virtually, predicting the plating thickness and distribution across the PCB surface. By using this tool, designers can optimize their designs for better plating quality, reducing the risk of defects and improving the overall reliability of the PCB.

How PCB Plating Simulation Works

PCB Plating Simulation works by using advanced algorithms to model the electrochemical processes involved in PCB plating. The software takes into account various factors that affect the plating process, such as:

- The geometry and layout of the PCB

- The material properties of the copper traces and the plating solution

- The operating conditions of the plating bath, such as temperature, agitation, and current density

By inputting these parameters into the simulation, designers can predict the plating thickness and distribution across the PCB surface. The software generates a 3D model of the PCB, showing the plating thickness at every point on the surface. This allows designers to identify areas of uneven plating or potential defects, and make necessary adjustments to the design or process parameters.

Advantages of PCB Plating Simulation

Using PCB Plating Simulation offers several advantages over traditional trial-and-error methods of optimizing the plating process:

-

Reduced time and cost: By simulating the plating process virtually, designers can avoid the need for multiple physical prototypes and testing iterations. This can significantly reduce the time and cost associated with PCB development.

-

Improved plating quality: PCB Plating Simulation allows designers to optimize the plating process for better uniformity and thickness distribution. This can help reduce the risk of defects such as voids, thin spots, or overplating, improving the overall quality and reliability of the PCB.

-

Enhanced design flexibility: By predicting the plating behavior early in the design process, designers can make informed decisions about the PCB layout and geometry. This can help them optimize the design for better manufacturability and performance, without compromising on the plating quality.

-

Faster time-to-market: By streamlining the PCB development process and reducing the need for physical testing, PCB Plating Simulation can help companies bring their products to market faster. This can be a significant competitive advantage in today’s fast-paced electronics industry.

Case Studies

To demonstrate the effectiveness of PCB Plating Simulation, let’s look at some real-world case studies where this tool has been used successfully.

Case Study 1: Automotive ECU

In this case study, an automotive electronics manufacturer was facing challenges with the plating quality of their Engine Control Unit (ECU) PCBs. The ECUs were experiencing intermittent failures due to thin spots and voids in the plating, which were causing connectivity issues and signal integrity problems.

By using PCB Plating Simulation, the manufacturer was able to identify the root cause of the plating issues. The simulation revealed that the PCB layout had several areas of high current density, which were causing uneven plating distribution. By modifying the layout and optimizing the plating parameters, the manufacturer was able to improve the plating uniformity and eliminate the defects.

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Plating Thickness | 25-35 μm | 30-32 μm |

| Plating Uniformity | ± 20% | ± 5% |

| Defect Rate | 5% | 0.5% |

As shown in the table above, the optimization using PCB Plating Simulation resulted in significant improvements in the plating quality. The plating thickness became more consistent, with a tighter tolerance range, and the uniformity improved from ± 20% to ± 5%. Most importantly, the defect rate dropped from 5% to 0.5%, virtually eliminating the intermittent failures and improving the overall reliability of the ECUs.

Case Study 2: High-Density Interconnect (HDI) PCB

In another case study, a consumer electronics company was developing a new smartphone with a complex HDI PCB. The PCB had multiple layers and fine-pitch features, which made the plating process challenging. The company was facing yield issues due to overplating and bridging between the closely spaced traces.

By using PCB Plating Simulation, the company was able to optimize the plating process for the HDI PCB. The simulation helped identify the areas of high current density and potential bridging, allowing the designers to modify the trace spacing and plating parameters accordingly.

| Parameter | Before Optimization | After Optimization |

|---|---|---|

| Trace Spacing | 50 μm | 75 μm |

| Plating Thickness | 15-25 μm | 18-22 μm |

| Bridging Rate | 10% | 1% |

As shown in the table above, the optimization using PCB Plating Simulation allowed the company to increase the trace spacing from 50 μm to 75 μm, which reduced the risk of bridging. The plating thickness also became more consistent, with a tighter tolerance range. As a result, the bridging rate dropped from 10% to 1%, significantly improving the yield and reliability of the HDI PCBs.

Best Practices for Using PCB Plating Simulation

To get the most out of PCB Plating Simulation, it’s important to follow some best practices:

-

Start early: Incorporate PCB Plating Simulation early in the design process, ideally during the layout and routing phase. This allows you to optimize the design for better plating quality from the beginning, rather than trying to fix issues later on.

-

Use accurate models: Ensure that the simulation models are accurate and up-to-date, based on the latest material properties and process parameters. This may require collaboration with your PCB fabricator or plating service provider.

-

Validate with physical testing: While PCB Plating Simulation can provide valuable insights and predictions, it’s still important to validate the results with physical testing. Use the simulation results to guide your testing and verification process, but don’t rely on them exclusively.

-

Iterate and refine: Use the feedback from the simulation and physical testing to iterate and refine your design. PCB Plating Simulation is not a one-time solution, but rather a tool that can be used throughout the design process to continuously improve the plating quality.

FAQ

-

What is PCB Plating Simulation?

PCB Plating Simulation is a software tool that allows PCB designers to virtually simulate the electrochemical plating process, predicting the plating thickness and distribution across the PCB surface. -

Why is PCB Plating Simulation important?

PCB Plating Simulation is important because it allows designers to optimize their designs for better plating quality, reducing the risk of defects and improving the overall reliability of the PCB. It can also help reduce the time and cost associated with physical prototyping and testing. -

What factors does PCB Plating Simulation take into account?

PCB Plating Simulation takes into account various factors that affect the plating process, such as the geometry and layout of the PCB, the material properties of the copper traces and plating solution, and the operating conditions of the plating bath. -

How does PCB Plating Simulation work?

PCB Plating Simulation works by using advanced algorithms to model the electrochemical processes involved in PCB plating. It generates a 3D model of the PCB, showing the plating thickness at every point on the surface, allowing designers to identify areas of uneven plating or potential defects. -

What are some best practices for using PCB Plating Simulation?

Some best practices for using PCB Plating Simulation include starting early in the design process, using accurate models, validating with physical testing, and iterating and refining the design based on the simulation results and feedback.

Conclusion

PCB Plating Simulation is a powerful tool that can help PCB designers optimize their designs for better plating quality, reducing the risk of defects and improving the overall reliability of the PCB. By using advanced algorithms to model the electrochemical plating process, PCB Plating Simulation allows designers to predict the plating thickness and distribution across the PCB surface, identifying areas of potential issues and making necessary adjustments.

As demonstrated in the case studies, PCB Plating Simulation has been successfully used to improve the plating quality and yield of various types of PCBs, from automotive ECUs to high-density interconnects. By following best practices and incorporating PCB Plating Simulation into their design process, PCB designers can unlock new levels of efficiency, reliability, and innovation in their products.

No responses yet