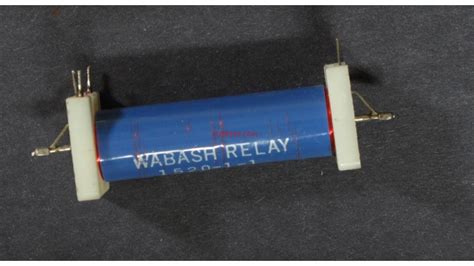

Introduction to Reed Relays

A reed relay is an electromagnetic switch that uses a magnetic field to control the opening and closing of one or more reed switches. It consists of a coil, a magnetic actuator, and a set of reed switches. When current flows through the coil, it generates a magnetic field that attracts the actuator, which in turn causes the reed switches to close or open, depending on the relay’s configuration.

Reed relays are known for their fast switching speeds, low power consumption, and ability to switch low-level signals. They are widely used in various applications, such as telecommunications, test equipment, automotive electronics, and industrial control systems.

Key Components of a Reed Relay

-

Reed Switches: These are the main switching elements in a reed relay. They consist of two ferromagnetic contacts sealed in a glass envelope filled with an inert gas, typically nitrogen or a vacuum. When a magnetic field is applied, the contacts attract each other and close the circuit.

-

Coil: The coil is an electromagnetic winding that generates a magnetic field when current flows through it. The strength of the magnetic field depends on the number of turns in the coil and the amount of current flowing through it.

-

Magnetic Actuator: The magnetic actuator is a ferromagnetic material, usually a metal plate or armature, that is attracted to the magnetic field generated by the coil. When the actuator moves, it causes the reed switches to open or close.

How Reed Relays Work

When current flows through the coil of a reed relay, it generates a magnetic field that attracts the magnetic actuator. The actuator, in turn, causes the reed switches to close or open, depending on the relay’s configuration. There are two main types of reed relays:

-

Normally Open (NO) Reed Relay: In this configuration, the reed switches are open when no current flows through the coil. When current is applied, the magnetic field causes the switches to close, completing the circuit.

-

Normally Closed (NC) Reed Relay: In this configuration, the reed switches are closed when no current flows through the coil. When current is applied, the magnetic field causes the switches to open, breaking the circuit.

Some reed relays also have a combination of NO and NC contacts, allowing for more complex switching arrangements.

Reed Relay Switching Characteristics

Reed relays have several important switching characteristics that make them suitable for various applications:

-

Switching Speed: Reed relays have fast switching speeds, typically in the range of 0.5 to 2 milliseconds. This makes them suitable for applications that require rapid switching, such as pulse circuits or high-speed control systems.

-

Switching Current: Reed relays can switch a wide range of currents, from a few microamperes to several amperes, depending on the contact material and size. However, it is essential to ensure that the switched current does not exceed the relay’s maximum rating to avoid damaging the contacts.

-

Switching Voltage: Reed relays can switch voltages ranging from a few millivolts to several kilovolts. The maximum switching voltage depends on the contact gap and the dielectric strength of the gas or vacuum inside the reed switch.

-

Contact Resistance: Reed relays have low contact resistance, typically in the range of 50 to 100 milliohms. This makes them suitable for switching low-level signals without introducing significant voltage drops or signal distortion.

Advantages of Reed Relays

Reed relays offer several advantages over other types of relays, such as electromechanical relays or solid-state relays:

-

Small Size: Reed relays are compact and lightweight, making them suitable for applications where space is limited, such as in portable devices or high-density circuit boards.

-

Low Power Consumption: Reed relays require very little power to operate, typically in the range of a few milliwatts to a few watts. This makes them suitable for battery-powered devices or applications where power efficiency is critical.

-

High Isolation: Reed relays provide excellent isolation between the coil and the contacts, typically in the range of 10^9 to 10^15 ohms. This helps prevent noise and interference from coupling between the control circuit and the switched circuit.

-

Long Life: Reed relays have a long operating life, typically in the range of 10^7 to 10^9 switching cycles, depending on the switched load and the operating conditions. This makes them suitable for applications that require frequent switching or long-term reliability.

-

Low Contact Bounce: Reed relays have low contact bounce, typically less than 100 microseconds, which helps reduce switching noise and improve signal integrity.

Disadvantages of Reed Relays

Despite their many advantages, reed relays also have some limitations and disadvantages:

-

Limited Current Handling: Reed relays have limited current handling capacity compared to other types of relays, such as electromechanical relays. The maximum switched current depends on the contact material and size, but it is typically in the range of a few amperes.

-

Sensitivity to External Magnetic Fields: Reed relays are sensitive to external magnetic fields, which can cause unwanted switching or contact chatter. This can be mitigated by using magnetic shielding or by orienting the relay to minimize the effect of external fields.

-

Fragility: The glass envelope of the reed switch is fragile and can be damaged by mechanical shock or vibration. Care must be taken when handling and mounting reed relays to avoid damaging the switch.

-

Limited Temperature Range: Reed relays have a limited operating temperature range, typically from -40°C to +125°C. Extreme temperatures can cause the contact materials to degrade or the glass envelope to crack.

Applications of Reed Relays

Reed relays are used in a wide range of applications, including:

-

Telecommunications: Reed relays are used in telephone exchanges, modems, and other communication equipment to switch audio and data signals.

-

Test and Measurement: Reed relays are used in test equipment, such as oscilloscopes, multimeters, and data acquisition systems, to switch low-level signals and high-impedance sources.

-

Automotive Electronics: Reed relays are used in automotive applications, such as engine control modules, anti-lock braking systems, and keyless entry systems, to switch low-current signals and provide isolation between circuits.

-

Industrial Control: Reed relays are used in industrial control systems, such as programmable logic controllers (PLCs), to switch low-level signals and provide isolation between the control circuit and the switched loads.

-

Medical Equipment: Reed relays are used in medical equipment, such as patient monitoring systems and diagnostic devices, to switch low-level signals and provide isolation between the patient and the equipment.

Selecting the Right Reed Relay

When selecting a reed relay for a specific application, several factors should be considered:

-

Coil Voltage and Current: The coil voltage and current should be compatible with the control circuit and should not exceed the relay’s maximum ratings.

-

Switching Current and Voltage: The switched current and voltage should be within the relay’s maximum ratings and should be compatible with the load being switched.

-

Contact Configuration: The contact configuration (NO, NC, or a combination) should match the requirements of the application.

-

Switching Speed: The switching speed should be fast enough to meet the application’s requirements, particularly in high-speed control or pulse circuits.

-

Environmental Conditions: The relay should be able to operate reliably in the expected environmental conditions, such as temperature, humidity, and vibration.

-

Packaging and Mounting: The relay’s packaging and mounting options should be compatible with the circuit board layout and the available space in the enclosure.

Reed Relay Specifications

When selecting a reed relay, it is essential to understand the key specifications and how they relate to the application requirements. Some of the most important reed relay specifications include:

| Specification | Description |

|---|---|

| Coil Voltage | The nominal voltage required to energize the coil and switch the contacts. |

| Coil Current | The current flowing through the coil when it is energized at the nominal voltage. |

| Coil Resistance | The resistance of the coil winding, which determines the coil current at a given voltage. |

| Switching Voltage | The maximum voltage that can be switched by the relay contacts. |

| Switching Current | The maximum current that can be switched by the relay contacts. |

| Contact Resistance | The resistance of the closed contacts, which determines the voltage drop across the relay. |

| Insulation Resistance | The resistance between the coil and the contacts, which determines the isolation between the control circuit and the switched circuit. |

| Operate Time | The time required for the contacts to close after the coil is energized. |

| Release Time | The time required for the contacts to open after the coil is de-energized. |

| Mechanical Life | The number of switching cycles the relay can withstand without failure due to mechanical wear. |

| Electrical Life | The number of switching cycles the relay can withstand without failure due to electrical wear, such as contact erosion or coil burnout. |

Reed Relay Testing and Troubleshooting

To ensure reliable operation and long service life, reed relays should be tested and inspected regularly. Some common testing and troubleshooting methods include:

-

Visual Inspection: Visually inspect the relay for signs of damage, such as cracks in the glass envelope, corroded contacts, or loose connections.

-

Coil Resistance Test: Measure the coil resistance using an ohmmeter and compare it to the specified value. A significant deviation from the specified value may indicate a damaged coil or incorrect relay selection.

-

Contact Resistance Test: Measure the contact resistance using a low-voltage, high-impedance ohmmeter. A high contact resistance may indicate dirty or corroded contacts, which can be cleaned with a suitable solvent or contact cleaner.

-

Insulation Resistance Test: Measure the insulation resistance between the coil and the contacts using a high-voltage insulation tester or megohmmeter. A low insulation resistance may indicate moisture ingress or insulation breakdown, which can lead to relay failure.

-

Switching Test: Test the relay’s switching function by energizing the coil and measuring the voltage or current across the contacts. Verify that the contacts close and open as expected and that there is no contact bounce or chatter.

If a reed relay fails any of these tests or exhibits abnormal behavior, it should be replaced with a new unit. In some cases, the relay may be repairable by cleaning the contacts or replacing the coil, but this should only be attempted by qualified personnel.

Frequently Asked Questions (FAQ)

- What is the difference between a reed relay and a solid-state relay?

-

A reed relay uses mechanical contacts to switch the load, while a solid-state relay uses semiconductor devices, such as transistors or thyristors. Reed relays offer higher isolation and lower leakage current, while solid-state relays offer faster switching speeds and higher current handling capacity.

-

Can reed relays be used to switch AC loads?

-

Yes, reed relays can switch both AC and DC loads, provided that the switched voltage and current are within the relay’s maximum ratings. However, when switching AC loads, the relay contacts may experience increased wear due to the higher voltage stress and arcing.

-

How do I protect a reed relay from voltage spikes and surges?

-

Reed relays can be protected from voltage spikes and surges by using transient suppression devices, such as Varistors or gas discharge tubes, connected across the coil or the contacts. These devices absorb the excess energy and limit the voltage to a safe level.

-

What is the typical life expectancy of a reed relay?

-

The life expectancy of a reed relay depends on the switched load, the operating conditions, and the relay’s specifications. Typically, reed relays have a mechanical life of 10^7 to 10^9 switching cycles and an electrical life of 10^5 to 10^7 switching cycles, depending on the switched current and voltage.

-

Can reed relays be used in explosive or hazardous environments?

- Reed relays can be used in explosive or hazardous environments, provided that they are properly sealed and rated for the specific hazardous location. Special reed relays with hermetically sealed contacts and explosion-proof enclosures are available for use in such environments.

Conclusion

Reed relays are versatile and reliable switching devices that offer many advantages over other types of relays, such as small size, low power consumption, high isolation, and long life. They are widely used in various applications, from telecommunications and test equipment to automotive electronics and industrial control systems.

When selecting a reed relay, it is essential to consider the application requirements, such as the coil voltage and current, switching current and voltage, contact configuration, switching speed, and environmental conditions. By understanding the key specifications and testing methods, engineers and technicians can ensure that the relay operates reliably and meets the application’s performance and safety requirements.

As technology advances, reed relays continue to evolve and find new applications in emerging fields, such as renewable energy, electric vehicles, and the Internet of Things (IoT). With their unique combination of mechanical and electrical properties, reed relays are likely to remain an essential component in many electronic systems for years to come.

No responses yet