Introduction to Rigid-Flex PCB

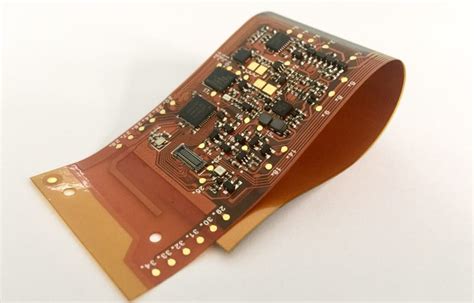

Rigid-Flex PCB, also known as rigid-flexible printed circuit board, is a unique combination of rigid and Flexible PCB technologies. It consists of multiple layers of flexible PCB Substrates integrated with rigid PCB sections, allowing for both the stability of rigid boards and the flexibility of flex circuits in a single design. This innovative approach offers numerous advantages over traditional flexible PCB in electronic projects.

Advantages of Rigid-Flex PCB over Flexible PCB

1. Enhanced Mechanical Stability

One of the key benefits of using rigid-flex PCB is the enhanced mechanical stability it provides compared to flexible PCB. The rigid sections of the board offer structural support and protect the sensitive electronic components from mechanical stress and vibration. This is particularly important in applications where the device is subject to frequent movement or harsh environmental conditions.

| PCB Type | Mechanical Stability | Vibration Resistance | Durability |

|---|---|---|---|

| Rigid-Flex PCB | High | Excellent | Long-lasting |

| Flexible PCB | Low | Fair | Limited |

2. Improved Signal Integrity

Rigid-flex PCB designs offer improved signal integrity compared to flexible PCB. The rigid sections of the board provide a stable platform for critical signal traces, reducing the risk of signal distortion or loss due to flexing or movement. This is crucial in high-speed applications where maintaining signal integrity is essential for optimal performance.

3. Space Savings and Miniaturization

By combining rigid and flexible sections in a single PCB, Rigid-Flex Designs enable significant space savings and miniaturization. The flexible sections allow for the folding and bending of the board, allowing it to fit into tight spaces or conform to unique device shapes. This eliminates the need for multiple separate boards and connectors, reducing the overall size and weight of the electronic device.

| PCB Type | Space Savings | Miniaturization | Packaging Efficiency |

|---|---|---|---|

| Rigid-Flex PCB | High | Excellent | Optimized |

| Flexible PCB | Moderate | Good | Limited |

4. Increased Reliability

Rigid-flex PCB designs offer increased reliability compared to flexible PCB. The rigid sections provide a stable foundation for the electronic components, reducing the risk of component failure due to flexing or movement. Additionally, the integrated nature of rigid-flex boards eliminates the need for connectors and cables between separate boards, further enhancing reliability by reducing potential points of failure.

5. Cost-Effectiveness

While rigid-flex PCB may have a higher initial cost compared to flexible PCB, it can be more cost-effective in the long run. The integration of rigid and flexible sections in a single board reduces the number of required components, simplifies assembly, and minimizes the need for additional connectors and cables. This can lead to lower manufacturing and assembly costs, especially in high-volume production.

Applications of Rigid-Flex PCB

Rigid-flex PCB finds applications in various industries and electronic projects where reliability, space savings, and flexibility are critical. Some common applications include:

- Wearable Electronics

- Medical Devices

- Aerospace and Defense Systems

- Automotive Electronics

- Industrial Automation and Robotics

Designing Rigid-Flex PCB

Designing rigid-flex PCB requires careful consideration of several factors to ensure optimal performance and reliability. Some key design considerations include:

-

Material Selection: Choosing the appropriate flexible and rigid substrate materials based on the application requirements.

-

Layer Stackup: Determining the number and arrangement of layers in the rigid-flex PCB to achieve the desired electrical and mechanical properties.

-

Bend Radius: Specifying the minimum bend radius for the flexible sections to avoid excessive stress and ensure long-term reliability.

-

Trace Routing: Routing traces and placing components strategically to minimize stress on the flexible sections during bending.

-

Shielding and Grounding: Implementing proper shielding and grounding techniques to mitigate electromagnetic interference (EMI) and ensure signal integrity.

Manufacturing Rigid-Flex PCB

Manufacturing rigid-flex PCB involves a combination of rigid and flexible PCB fabrication processes. The key steps in the manufacturing process include:

-

Substrate Preparation: Cutting and laminating the flexible and rigid substrate materials.

-

Patterning and Etching: Creating the conductive traces and pads on the substrates using photolithography and etching techniques.

-

Lamination: Bonding the flexible and rigid layers together using adhesives and pressure.

-

Drilling and Plating: Drilling through-holes and plating them with conductive materials to establish electrical connections between layers.

-

Surface Finishing: Applying surface finishes, such as ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative), to protect the exposed copper and enhance solderability.

FAQs

-

Q: What is the difference between rigid-flex PCB and flexible PCB?

A: Rigid-flex PCB combines rigid and flexible sections in a single board, offering both stability and flexibility. Flexible PCB, on the other hand, consists entirely of flexible substrates and lacks the structural support provided by rigid sections. -

Q: What are the advantages of using rigid-flex PCB in electronic projects?

A: Rigid-flex PCB offers several advantages, including enhanced mechanical stability, improved signal integrity, space savings and miniaturization, increased reliability, and cost-effectiveness in the long run. -

Q: In what industries is rigid-flex PCB commonly used?

A: Rigid-flex PCB finds applications in various industries, such as wearable electronics, medical devices, aerospace and defense systems, automotive electronics, and industrial automation and robotics. -

Q: What are the key considerations when designing rigid-flex PCB?

A: When designing rigid-flex PCB, key considerations include material selection, layer stackup, bend radius, trace routing, and shielding and grounding techniques. -

Q: How is rigid-flex PCB manufactured?

A: Rigid-flex PCB manufacturing involves a combination of rigid and flexible PCB fabrication processes, including substrate preparation, patterning and etching, lamination, drilling and plating, and surface finishing.

Conclusion

Rigid-flex PCB offers a superior solution to flexible PCB in electronic projects that require a combination of stability, flexibility, and reliability. By integrating rigid and flexible sections in a single board, rigid-flex PCB enables enhanced mechanical stability, improved signal integrity, space savings, and increased reliability. While the initial cost may be higher than flexible PCB, the long-term benefits and cost-effectiveness make rigid-flex PCB a preferred choice for a wide range of applications.

As technology continues to advance and electronic devices become more complex and compact, the demand for rigid-flex PCB is expected to grow. Designers and manufacturers who embrace this innovative technology can unlock new possibilities in Electronic Design and stay ahead of the curve in their respective industries.

No responses yet