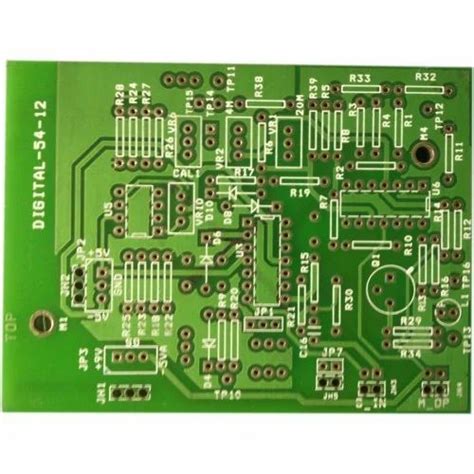

What is FR4 PCB?

FR4 (Flame Retardant 4) is a type of material used in the manufacturing of printed circuit boards (PCBs). It is a composite material composed of woven fiberglass cloth with an epoxy resin binder that is flame resistant. FR4 PCB is the most common type of PCB material used in electronic devices due to its excellent mechanical, electrical, and thermal properties.

Composition of FR4 PCB

FR4 PCB is made up of multiple layers of copper foil, fiberglass, and epoxy resin. The number of layers can vary depending on the complexity of the circuit design. The typical composition of an FR4 PCB is as follows:

| Layer | Material |

|---|---|

| Copper Foil | Thin layer of copper on both sides |

| Prepreg | Fiberglass impregnated with epoxy resin |

| Core | Fiberglass impregnated with epoxy resin |

The copper foil is used for the conductive traces, pads, and vias of the circuit. The prepreg and core layers provide insulation and structural support to the PCB.

Properties of FR4 PCB

FR4 PCB has several properties that make it an ideal choice for electronic applications:

- High dielectric strength

- Good mechanical strength and dimensional stability

- Excellent thermal stability

- Flame retardant

- Moisture resistant

These properties ensure that FR4 PCBs can withstand various environmental conditions and stresses during operation.

FR4 PCB Manufacturing Process

The manufacturing process of FR4 PCBs involves several steps, each of which is critical to the quality and reliability of the final product.

Step 1: Design and Layout

The first step in FR4 PCB manufacturing is to design the circuit and create a layout. This is done using specialized PCB design software, such as Altium Designer or Eagle. The design includes the placement of components, routing of traces, and the creation of vias and pads.

Step 2: Material Selection

Once the design is complete, the appropriate FR4 material is selected based on the requirements of the application. The thickness, copper weight, and number of layers are determined at this stage.

Step 3: Printing and Etching

The next step is to print the circuit layout onto the FR4 material using a photoresist process. The copper foil is then etched away, leaving only the desired traces and pads.

Step 4: Lamination

After etching, the layers of FR4 material are stacked and laminated together under high pressure and temperature. This process bonds the layers together and creates a solid, rigid board.

Step 5: Drilling

Holes are drilled through the laminated board to create vias and mounting holes for components. The drilling process is typically done using CNC machines for precision and accuracy.

Step 6: Plating

The drilled holes are then plated with copper to create a conductive path between layers. This is done using an electroplating process.

Step 7: Solder Mask and Silkscreen

A solder mask is applied to the board to protect the copper traces from oxidation and prevent solder bridges during assembly. A silkscreen layer is also added to provide labels and markings for components.

Step 8: Surface Finish

Finally, a surface finish is applied to the exposed copper areas to prevent oxidation and improve solderability. Common surface finishes include HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), and OSP (Organic Solderability Preservative).

Advantages of FR4 PCB

FR4 PCBs offer several advantages over other types of PCB materials:

-

Cost-effective: FR4 is relatively inexpensive compared to other PCB materials, making it a cost-effective choice for many applications.

-

Versatile: FR4 can be used in a wide range of applications, from consumer electronics to industrial equipment.

-

Reliable: FR4 PCBs are known for their reliability and durability, even in harsh environments.

-

Easy to manufacture: The manufacturing process for FR4 PCBs is well-established and can be easily scaled up for high-volume production.

Applications of FR4 PCB

FR4 PCBs are used in a variety of electronic applications, including:

-

Consumer electronics: Smartphones, laptops, tablets, and other consumer devices.

-

Industrial equipment: Sensors, controllers, and automation systems.

-

Automotive electronics: Engine control units, infotainment systems, and safety devices.

-

Medical devices: Diagnostic equipment, monitoring systems, and implantable devices.

-

Aerospace and defense: Avionics, communication systems, and radar equipment.

Frequently Asked Questions (FAQ)

1. What does FR4 stand for?

FR4 stands for Flame Retardant 4, which indicates that the material is designed to be flame resistant.

2. Can FR4 PCBs be used for high-frequency applications?

Yes, FR4 PCBs can be used for high-frequency applications up to a certain point. However, for very high-frequency applications (above 10 GHz), other materials such as Rogers or Teflon may be more suitable.

3. What is the maximum number of layers that can be used in an FR4 PCB?

The maximum number of layers in an FR4 PCB is typically around 20-24 layers. Beyond that, the manufacturing process becomes more complex and expensive.

4. How does the thickness of the FR4 material affect the performance of the PCB?

The thickness of the FR4 material can affect the impedance and signal integrity of the PCB. Thicker boards generally have better mechanical strength and thermal stability, while thinner boards are more flexible and can be used in space-constrained applications.

5. What is the typical lead time for FR4 PCB manufacturing?

The lead time for FR4 PCB manufacturing can vary depending on the complexity of the design and the volume of the order. Typical lead times range from 1-2 weeks for simple designs to 4-6 weeks for more complex, high-volume orders.

Conclusion

FR4 PCB is the most widely used material in the manufacturing of printed circuit boards. Its excellent mechanical, electrical, and thermal properties make it an ideal choice for a wide range of electronic applications. The manufacturing process for FR4 PCBs involves several critical steps, from design and layout to surface finish and inspection.

As electronic devices continue to become more complex and sophisticated, the demand for high-quality FR4 PCBs will only continue to grow. By understanding the properties and manufacturing process of FR4 PCBs, designers and engineers can create reliable, high-performance electronic products that meet the needs of today’s market.

No responses yet