Introduction to PDF Conversion for PCB Manufacturing

When it comes to PCB manufacturing, the industry-standard file formats are Gerber and NC Drill. These formats are used to communicate the design data to the PCB fabricator, ensuring accurate and efficient production of printed circuit boards. However, many PCB design software packages generate output files in PDF format, which is not directly compatible with the manufacturing process. In this article, we will explore the process of converting PDF files to Gerber and NC Drill formats, enabling seamless integration with PCB Fabrication workflows.

What are Gerber and NC Drill Formats?

Gerber and NC Drill are two essential file formats used in the PCB manufacturing industry. Let’s take a closer look at each format:

Gerber Format

Gerber format, also known as RS-274X, is a standard file format used to describe the 2D layout of a PCB. It contains information about the copper layers, solder mask, silkscreen, and other features of the PCB design. Gerber files are generated for each layer of the PCB, such as the top and bottom copper layers, solder mask layers, and silkscreen layers. These files are then used by the PCB fabricator to create the physical layers of the PCB.

NC Drill Format

NC Drill format, also known as Excellon format, is used to specify the locations and sizes of the drilled holes on a PCB. It contains information about the drill bit sizes, the coordinates of each hole, and the drilling sequence. The NC Drill file is essential for the PCB fabricator to accurately drill the holes in the PCB, ensuring proper component placement and connectivity.

Why Convert PDF to Gerber and NC Drill?

While PDF is a widely used file format for document exchange and printing, it is not directly suitable for PCB manufacturing. PCB fabricators require Gerber and NC Drill files to produce the physical PCBs accurately. Here are some reasons why converting PDF to Gerber and NC Drill formats is necessary:

-

Compatibility with PCB Fabrication Processes: Gerber and NC Drill formats are specifically designed for PCB manufacturing. They contain the necessary information required by the fabrication equipment to produce the PCBs accurately. PDF files, on the other hand, are not optimized for this purpose and may lack the required level of detail and precision.

-

Ensuring Data Integrity: Converting PDF to Gerber and NC Drill formats helps maintain the integrity of the PCB design data. PDF files can be prone to errors, such as incorrect scaling or loss of resolution, which can lead to manufacturing issues. By converting to Gerber and NC Drill formats, you ensure that the design data remains accurate and consistent throughout the fabrication process.

-

Streamlining the Manufacturing Workflow: PCB fabricators have well-established workflows that revolve around Gerber and NC Drill files. By providing the design data in these formats, you can seamlessly integrate your PCB design into their manufacturing process. This streamlines the overall workflow, reduces the chances of errors, and facilitates effective communication between the designer and the fabricator.

Methods for Converting PDF to Gerber and NC Drill

There are several methods available for converting PDF files to Gerber and NC Drill formats. Let’s explore some of the common approaches:

1. Using PCB Design Software

Many PCB design software packages, such as Altium Designer, KiCad, and Eagle, have built-in functionality to export the design data in Gerber and NC Drill formats. If you have access to the original PCB design files, you can use the software’s export features to generate the required manufacturing files directly.

Here’s a general step-by-step process for exporting Gerber and NC Drill files using PCB design software:

- Open the PCB design project in your software.

- Ensure that the design is complete and error-free.

- Navigate to the File menu and look for options related to manufacturing outputs or CAM (Computer-Aided Manufacturing) outputs.

- Select the Gerber and NC Drill file formats from the available options.

- Configure the export settings, such as layer selection, file naming conventions, and output directory.

- Generate the Gerber and NC Drill files by clicking the appropriate export or generate button.

It’s important to note that the specific steps and terminology may vary depending on the PCB design software you are using. Refer to the software’s documentation or support resources for detailed instructions on exporting Gerber and NC Drill files.

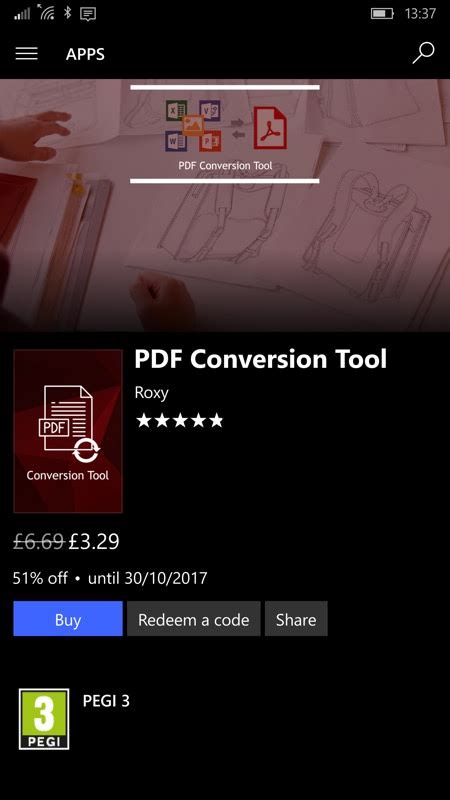

2. Using Third-Party Conversion Tools

If you don’t have access to the original PCB design files or if your design software doesn’t support direct Gerber and NC Drill export, you can use third-party conversion tools. These tools are specifically designed to convert PDF files to Gerber and NC Drill formats.

Some popular third-party conversion tools include:

- PDF2Gerber

- PCB-GCode

- CAM350

- ViewMate

These tools typically offer a user-friendly interface where you can import the PDF file, specify the conversion settings, and generate the Gerber and NC Drill files. The conversion process may involve some manual intervention, such as layer assignment and drill file configuration.

When using third-party conversion tools, it’s crucial to ensure the accuracy and completeness of the converted files. Verify that all the necessary layers are present, the dimensions are correct, and the drill holes are properly defined. It’s also a good practice to review the generated files using a Gerber viewer to catch any potential issues before sending them to the PCB fabricator.

3. Outsourcing the Conversion Process

If you lack the necessary software or expertise to convert PDF files to Gerber and NC Drill formats, you can outsource the conversion process to specialized service providers. Many PCB fabrication companies offer file conversion services as part of their overall manufacturing solutions.

When outsourcing the conversion process, you typically need to provide the PDF files along with any additional design specifications or requirements. The service provider will then handle the conversion and provide you with the Gerber and NC Drill files ready for manufacturing.

Outsourcing the conversion process can save time and effort, especially if you are not familiar with the technicalities of Gerber and NC Drill file generation. However, it’s important to choose a reputable service provider with experience in PCB file conversion to ensure the quality and accuracy of the converted files.

Best Practices for PDF to Gerber and NC Drill Conversion

To ensure a smooth and successful conversion process, consider the following best practices:

-

Use High-Quality PDF Files: Start with high-quality PDF files that accurately represent your PCB design. Ensure that the PDF files are generated from the original design software with the correct settings, such as appropriate resolution and layer separation.

-

Include All Necessary Layers: Make sure that the PDF files include all the required layers for PCB manufacturing, such as copper layers, solder mask, silkscreen, and drill layers. Incomplete or missing layers can lead to manufacturing errors.

-

Specify Clear Layer Naming Conventions: Use clear and consistent naming conventions for the layers in your PDF files. This helps in accurately mapping the layers to their corresponding Gerber and NC Drill files during the conversion process.

-

Provide Accurate Drill Information: Include accurate information about the drill holes, such as hole sizes, locations, and tolerances. This information is critical for generating the NC Drill files and ensuring proper drilling during manufacturing.

-

Communicate Design Requirements: Clearly communicate any specific design requirements or constraints to the PCB fabricator or the service provider handling the file conversion. This includes any special materials, finishes, or tolerances that need to be considered during manufacturing.

-

Verify the Converted Files: Always verify the converted Gerber and NC Drill files before sending them for manufacturing. Use a Gerber viewer or a PCB design software to open and inspect the files, ensuring that all the layers are present, the dimensions are accurate, and the drill holes are properly defined.

-

Collaborate with the PCB Fabricator: Maintain open communication with your PCB fabricator throughout the conversion and manufacturing process. They can provide valuable guidance and feedback on file formatting, design optimization, and manufacturability aspects.

Frequently Asked Questions (FAQ)

-

Can I convert PDF files to Gerber and NC Drill formats using free software?

While there are some free tools available for PDF to Gerber and NC Drill conversion, they may have limitations in terms of features and accuracy. It’s recommended to use professional PCB design software or reliable third-party conversion tools to ensure the best results. -

What if I don’t have access to the original PCB design files?

If you don’t have access to the original PCB design files, you can still convert the PDF files to Gerber and NC Drill formats using third-party conversion tools or by outsourcing the conversion process to a specialized service provider. -

How long does the conversion process take?

The time required for PDF to Gerber and NC Drill conversion varies depending on the complexity of the PCB design and the method used for conversion. Using PCB design software with built-in export functionality is usually the quickest option, while using third-party tools or outsourcing the process may take longer. -

What should I do if the converted files have errors or inconsistencies?

If you encounter errors or inconsistencies in the converted Gerber and NC Drill files, first try to identify the source of the issue. Check if the original PDF files are complete and accurate. If the problem persists, reach out to the PCB fabricator or the service provider handling the conversion for assistance and guidance. -

Can I use the same Gerber and NC Drill files for different PCB fabricators?

Gerber and NC Drill formats are industry standards, so the same files can be used for different PCB fabricators. However, it’s always a good practice to communicate with the specific fabricator you are working with to ensure compatibility and adherence to their manufacturing guidelines.

Conclusion

Converting PDF files to Gerber and NC Drill formats is a crucial step in the PCB manufacturing process. By understanding the importance of these file formats and the available methods for conversion, you can ensure that your PCB design data is accurately translated for fabrication.

Whether you choose to use PCB design software, third-party conversion tools, or outsource the conversion process, following best practices and maintaining clear communication with your PCB fabricator are key to successful file conversion and manufacturing outcomes.

By adopting a systematic approach to PDF to Gerber and NC Drill conversion, you can streamline your PCB design workflow, minimize errors, and achieve high-quality manufactured PCBs that meet your design requirements.

| Conversion Method | Advantages | Disadvantages |

|---|---|---|

| PCB Design Software | – Direct export from the original design files – Ensures data accuracy and consistency – Quick and efficient process |

– Requires access to the original PCB design files – Limited to the software’s supported file formats |

| Third-Party Conversion Tools | – Supports conversion from PDF files – User-friendly interface for file import and conversion settings – Suitable when original design files are not available |

– May require manual intervention and layer assignment – Accuracy depends on the quality of the PDF files and the tool’s capabilities |

| Outsourcing the Conversion | – Saves time and effort – Leverages the expertise of specialized service providers – Ideal for those lacking software or technical knowledge |

– Relies on the service provider’s turnaround time – May incur additional costs for the conversion service |

Remember, the key to successful PDF to Gerber and NC Drill conversion lies in starting with high-quality PDF files, including all necessary layers, providing accurate drill information, and verifying the converted files before proceeding with manufacturing. By following these guidelines and collaborating closely with your PCB fabricator, you can ensure a smooth and efficient transition from design to fabrication.

No responses yet