Understanding Ferric Chloride

What is Ferric Chloride?

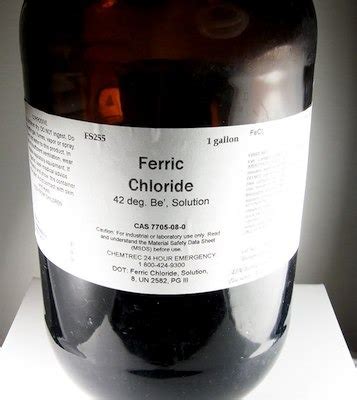

Ferric chloride, also known as iron(III) chloride, is a chemical compound with the formula FeCl3. It is a solid at room temperature and appears as dark green or brownish-black crystals. Ferric chloride is highly hygroscopic, meaning it readily absorbs moisture from the air, and it is soluble in water, forming a brownish-yellow solution.

Properties of Ferric Chloride

| Property | Value |

|---|---|

| Molecular Formula | FeCl3 |

| Molar Mass | 162.2 g/mol |

| Appearance | Dark green or brownish-black crystals |

| Density | 2.9 g/cm³ |

| Melting Point | 307.6 °C (585.7 °F) |

| Boiling Point | 316 °C (601 °F) (sublimes) |

| Solubility in Water (20°C) | 920 g/L |

Ferric chloride is a strong Lewis acid and an oxidizing agent. It readily hydrolyzes in water, forming complex ions and releasing heat. The aqueous solution of ferric chloride is acidic due to the hydrolysis reaction:

FeCl3 + 3H2O → Fe(OH)3 + 3HCl

Safety Precautions

Before handling ferric chloride, it is crucial to understand the potential hazards and take necessary safety precautions.

Hazards of Ferric Chloride

- Corrosive: Ferric chloride is corrosive to metals and can cause severe skin burns and eye damage.

- Irritant: It can cause respiratory irritation if inhaled and may cause digestive tract irritation if ingested.

- Environmental hazard: Ferric chloride is toxic to aquatic life and can have long-lasting effects on the environment.

Personal Protective Equipment (PPE)

When working with ferric chloride, always wear appropriate personal protective equipment:

- Goggles or face shield to protect eyes

- Rubber or neoprene gloves to protect hands

- Lab coat or protective clothing to protect skin

- Closed-toe shoes to protect feet

- Respirator or mask if working in poorly ventilated areas

Workplace Safety

- Work in a well-ventilated area or under a fume hood.

- Keep ferric chloride away from incompatible materials, such as strong bases, reducing agents, and combustible materials.

- Store ferric chloride in a cool, dry place, away from moisture and direct sunlight.

- Label containers clearly with the chemical name, concentration, and hazard information.

- Have a safety shower and eyewash station readily accessible in case of accidental exposure.

Mixing Ferric Chloride Solution

Materials and Equipment

- Ferric chloride crystals or anhydrous powder

- Distilled or deionized water

- Graduated cylinder or volumetric flask

- Stirring rod or magnetic stirrer

- Beaker or mixing container

- Balance or weighing scale

- pH meter (optional)

Procedure

-

Determine the desired concentration of ferric chloride solution. Common concentrations range from 1% to 50% by weight.

-

Calculate the amount of ferric chloride needed based on the desired concentration and volume of solution. Use the following formula:

Mass of FeCl3 (g) = Concentration (%) × Volume of solution (L) × Density of solution (g/mL)

For example, to prepare 1 liter of a 10% ferric chloride solution, assuming a solution density of 1.1 g/mL:

Mass of FeCl3 = 0.10 × 1 L × 1.1 g/mL = 110 g

-

Weigh the required amount of ferric chloride crystals or anhydrous powder using a balance or weighing scale.

-

Measure the necessary volume of distilled or deionized water using a graduated cylinder or volumetric flask.

-

In a beaker or mixing container, slowly add the ferric chloride to the water while stirring continuously. Use a stirring rod or magnetic stirrer to ensure uniform mixing.

-

Continue stirring until the ferric chloride is completely dissolved and the solution appears homogeneous.

-

If desired, check the pH of the solution using a pH meter. Ferric chloride solutions are typically acidic, with a pH range of 1-2.

-

Transfer the prepared ferric chloride solution to a labeled container for storage or immediate use.

Adjusting Concentration

If you need to adjust the concentration of a ferric chloride solution, you can either dilute it with water or add more ferric chloride.

To dilute a solution, use the following formula:

C1V1 = C2V2

Where:

– C1 is the initial concentration

– V1 is the initial volume

– C2 is the desired concentration

– V2 is the final volume

For example, if you have 500 mL of a 20% ferric chloride solution and want to dilute it to a 10% solution, you would solve for V2:

(20%)(500 mL) = (10%)(V2)

V2 = 1000 mL

This means you would need to add 500 mL of water to the original solution to achieve a 10% concentration.

To increase the concentration, simply add more ferric chloride crystals or anhydrous powder to the existing solution and stir until dissolved.

Applications of Ferric Chloride

Ferric chloride has numerous applications in various fields, including:

Etching Printed Circuit Boards (PCBs)

Ferric chloride is commonly used as an etchant in the production of printed circuit boards. It selectively removes copper from the substrate, leaving behind the desired circuit pattern. The etching process involves:

- Preparing the PCB with a resist pattern that protects the desired copper traces.

- Immersing the PCB in a heated ferric chloride solution (typically 30-45°C).

- Agitating the solution to ensure even etching.

- Monitoring the etching progress and removing the PCB once the unwanted copper is dissolved.

- Rinsing the PCB with water and removing the resist.

Wastewater Treatment

Ferric chloride is used in wastewater treatment plants to remove phosphates and other contaminants from the water. It acts as a coagulant, promoting the formation of flocs that settle out of the water, carrying the contaminants with them. The treatment process typically involves:

- Adding ferric chloride to the wastewater stream.

- Mixing the water to ensure even distribution of the coagulant.

- Allowing the flocs to form and settle in a sedimentation tank.

- Removing the clarified water from the top of the tank for further treatment or discharge.

- Collecting and disposing of the settled sludge.

Catalyst in Organic Synthesis

Ferric chloride serves as a Lewis acid catalyst in various organic synthesis reactions, such as:

- Friedel-Crafts alkylation and acylation

- Diels-Alder reactions

- Esterification reactions

- Polymerization reactions

In these applications, ferric chloride activates the substrate or promotes the formation of reactive intermediates, facilitating the desired chemical transformation.

Frequently Asked Questions (FAQ)

-

Q: What is the shelf life of ferric chloride solutions?

A: Ferric chloride solutions are relatively stable and can be stored for several months to a year, depending on the concentration and storage conditions. To maximize shelf life, store solutions in a cool, dry place, away from direct sunlight and moisture. Over time, the solution may darken or form a precipitate, but this does not necessarily affect its performance. -

Q: Can I reuse ferric chloride solutions?

A: In some applications, such as etching PCBs, ferric chloride solutions can be reused multiple times until they become saturated with dissolved copper. However, the etching rate may decrease as the solution becomes more saturated. In wastewater treatment, ferric chloride is consumed during the process and cannot be reused. -

Q: How do I dispose of ferric chloride solutions?

A: Ferric chloride solutions should not be poured down the drain or disposed of in the regular trash. Contact your local waste management authority for guidance on proper disposal methods. In general, ferric chloride solutions should be collected in clearly labeled containers and disposed of as hazardous waste through a licensed chemical waste handler. -

Q: Can I mix ferric chloride with other chemicals?

A: Ferric chloride is incompatible with certain chemicals, such as strong bases (e.g., sodium hydroxide), reducing agents (e.g., sodium borohydride), and combustible materials. Mixing ferric chloride with these substances can lead to violent reactions, heat generation, or the release of toxic gases. Always consult the safety data sheet (SDS) and follow proper handling guidelines when working with ferric chloride and other chemicals. -

Q: What should I do in case of accidental exposure to ferric chloride?

A: In case of skin contact, immediately flush the affected area with plenty of water for at least 15 minutes. Remove contaminated clothing and seek medical attention if irritation persists. For eye contact, rinse the eyes with water for at least 15 minutes, holding the eyelids apart to ensure thorough irrigation. Seek medical attention immediately. If inhaled, move to fresh air and seek medical attention if respiratory irritation occurs. If ingested, rinse the mouth with water and seek medical attention. Do not induce vomiting unless directed by medical personnel.

Conclusion

Mixing ferric chloride requires careful handling and adherence to safety protocols. By understanding the properties, hazards, and proper mixing procedures, you can prepare ferric chloride solutions for various applications, such as etching PCBs, treating wastewater, and catalyzing chemical reactions. Always prioritize safety by wearing appropriate personal protective equipment, working in well-ventilated areas, and properly storing and disposing of ferric chloride solutions. With the knowledge gained from this article, you are now equipped to handle ferric chloride mixing tasks safely and effectively.

No responses yet