Introduction to SMT Ordering

Surface Mount Technology (SMT) has revolutionized the electronics manufacturing industry by enabling the production of smaller, faster, and more reliable electronic devices. SMT ordering is a crucial step in the manufacturing process, as it involves providing accurate information and necessary files to ensure a smooth and efficient production process. This article will delve into the essential aspects of SMT ordering, including the required files, best practices, and common challenges.

Key Files for SMT Ordering

Bill of Materials (BOM)

The Bill of Materials (BOM) is a comprehensive list of all the components required to manufacture a printed circuit board (PCB) assembly. It includes the following information for each component:

- Reference designator

- Manufacturer part number

- Description

- Quantity

- Package type

- Value

A well-structured and accurate BOM is essential for ensuring that the correct components are ordered and used during the manufacturing process.

Gerber Files

Gerber files are the industry standard for PCB design data exchange. They contain the necessary information for manufacturing the PCB, including:

- Copper layers

- Solder mask

- Silkscreen

- Drill data

Gerber files should adhere to the latest format specifications (e.g., Gerber X2) to ensure compatibility with modern manufacturing equipment and avoid potential issues.

Assembly Drawings

Assembly drawings provide a visual representation of the PCB Assembly, including component placement and orientation. They serve as a guide for the manufacturing team and help ensure accurate assembly. Assembly drawings should include:

- Board dimensions

- Component locations

- Reference designators

- Special instructions (if applicable)

Clear and concise assembly drawings can help minimize errors and improve the overall quality of the final product.

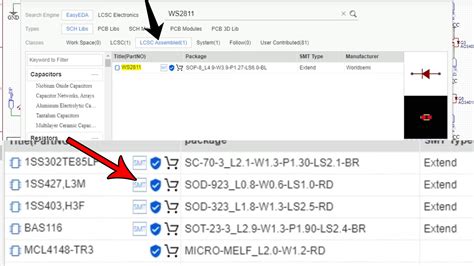

Pick and Place Files

Pick and place files, also known as centroid files or XY files, contain the coordinates for each component on the PCB. They are used by the pick and place machine to accurately position components during the assembly process. Pick and place files should include:

- Reference designator

- X and Y coordinates

- Rotation angle

- Side of the board (top or bottom)

Accurate pick and place files are crucial for ensuring proper component placement and reducing the risk of assembly errors.

IPC Standards and Requirements

The Institute for Printed Circuits (IPC) is a global trade association that develops standards for the electronics manufacturing industry. When creating files for SMT ordering, it is essential to adhere to the relevant IPC standards to ensure compatibility and quality. Some of the key IPC standards include:

- IPC-2581: Generic Requirements for Printed Board Assembly Products Manufacturing Description Data and Transfer Methodology

- IPC-7351B: Generic Requirements for Surface Mount Design and Land Pattern Standard

- IPC-A-610: Acceptability of Electronic Assemblies

Adhering to IPC standards helps ensure that the PCB assembly meets industry-recognized quality requirements and can be manufactured consistently by different suppliers.

Best Practices for SMT Ordering

Clear Communication with the Manufacturer

Clear communication with the PCB assembly manufacturer is essential for ensuring a smooth and efficient SMT ordering process. Provide all necessary files and information upfront, and be responsive to any questions or clarifications requested by the manufacturer. Establish a single point of contact to streamline communication and avoid confusion.

Consistent File Naming and Organization

Use consistent file naming conventions and organize files in a logical manner when submitting them for SMT ordering. This helps the manufacturer quickly identify and access the required files, reducing the risk of errors and delays. Consider using a naming scheme that includes the project name, version number, and file type.

Regular Design Reviews

Conduct regular design reviews to catch potential issues early in the process. This includes reviewing the BOM, Gerber files, assembly drawings, and pick and place files for accuracy and completeness. Involve key stakeholders, such as design engineers, procurement specialists, and quality control personnel, to ensure a comprehensive review process.

Prototype and Test Runs

Before placing a full production order, consider requesting a prototype or test run from the manufacturer. This allows you to validate the design, verify the manufacturing process, and identify any potential issues or improvements. Prototype and test runs can help minimize the risk of costly errors and delays in full-scale production.

Continuous Improvement

Embrace a continuous improvement mindset when it comes to SMT ordering. Regularly review and analyze the ordering process to identify areas for optimization. This may include streamlining file preparation, improving communication channels, or adopting new technologies and standards. By continuously refining the SMT ordering process, you can achieve greater efficiency, quality, and cost-effectiveness.

Common Challenges in SMT Ordering

Incomplete or Inaccurate Files

One of the most common challenges in SMT ordering is incomplete or inaccurate files. This can include missing or incorrect information in the BOM, Gerber files, assembly drawings, or pick and place files. Inaccurate files can lead to manufacturing delays, incorrect component placement, and quality issues in the final product.

To mitigate this challenge, establish a robust file preparation and review process. Use checklists to ensure that all necessary information is included and double-check files for accuracy before submitting them to the manufacturer.

Component Availability and Lead Times

Component availability and lead times can significantly impact the SMT ordering process. Long lead times for certain components can delay production and increase overall manufacturing time. Additionally, obsolete or hard-to-find components can pose sourcing challenges and may require redesigns or alternative solutions.

To address this challenge, work closely with your procurement team and the manufacturer to identify potential component availability issues early in the process. Consider using alternative components or redesigning the PCB to accommodate more readily available parts. Regularly monitor component lead times and adjust ordering schedules accordingly.

Design for Manufacturability (DFM) Issues

Design for Manufacturability (DFM) issues can arise when the PCB design does not consider the limitations and requirements of the manufacturing process. This can include component placement challenges, insufficient clearances, or incompatible materials. DFM issues can lead to manufacturing delays, reduced yields, and increased costs.

To overcome DFM issues, involve the manufacturer early in the design process. Share preliminary designs and seek feedback on potential manufacturability concerns. Adhere to industry-standard DFM guidelines and best practices, such as those outlined in IPC standards. Regularly review and update designs based on feedback from the manufacturing team.

Tips for Streamlining SMT Ordering

- Develop and maintain a comprehensive component library with up-to-date information on preferred parts, lead times, and availability.

- Establish a standardized file format and naming convention for all SMT ordering files, and ensure that all team members adhere to these standards.

- Implement automated file generation tools, such as CAD plugins or standalone software, to minimize manual errors and ensure consistency across projects.

- Foster a collaborative relationship with your PCB assembly manufacturer, and involve them early in the design process to identify and address potential manufacturability issues.

- Continuously monitor and analyze SMT ordering metrics, such as lead times, quality levels, and cost, to identify areas for improvement and optimize the overall process.

SMT Ordering Checklist

To ensure a smooth and efficient SMT ordering process, use the following checklist:

- [ ] BOM is complete, accurate, and includes all necessary information

- [ ] Gerber files are generated according to the latest format specifications

- [ ] Assembly drawings are clear, concise, and include all relevant information

- [ ] Pick and place files are accurate and include all required data

- [ ] All files adhere to relevant IPC standards and requirements

- [ ] Files are consistently named and organized

- [ ] Design reviews have been conducted and potential issues addressed

- [ ] Prototype or test run has been requested and reviewed (if applicable)

- [ ] Component availability and lead times have been verified

- [ ] DFM guidelines have been followed and manufacturability concerns addressed

By following this checklist and implementing the best practices outlined in this article, you can streamline your SMT ordering process, reduce errors and delays, and ensure the successful manufacturing of high-quality PCB assemblies.

Conclusion

SMT ordering is a critical step in the electronics manufacturing process, and accurate information and necessary files are essential for ensuring a smooth and efficient production process. By understanding the key files required for SMT ordering, adhering to industry standards and best practices, and addressing common challenges, you can optimize your SMT ordering process and achieve better results.

Remember to prioritize clear communication with your manufacturer, maintain consistent file organization, and continuously review and improve your processes. By doing so, you can reduce errors, minimize delays, and ultimately produce higher-quality PCB assemblies that meet your customers’ expectations.

Frequently Asked Questions (FAQ)

-

What is the difference between Gerber files and pick and place files?

Gerber files contain the necessary information for manufacturing the PCB, including copper layers, solder mask, and drill data. Pick and place files, on the other hand, contain the coordinates for each component on the PCB and are used by the pick and place machine to accurately position components during the assembly process. -

Why is it important to adhere to IPC standards when creating files for SMT ordering?

Adhering to IPC standards ensures that the PCB assembly meets industry-recognized quality requirements and can be manufactured consistently by different suppliers. It also helps ensure compatibility with modern manufacturing equipment and processes, reducing the risk of potential issues and delays. -

How can I address component availability and lead time challenges in SMT ordering?

To address component availability and lead time challenges, work closely with your procurement team and the manufacturer to identify potential issues early in the process. Consider using alternative components or redesigning the PCB to accommodate more readily available parts. Regularly monitor component lead times and adjust ordering schedules accordingly. -

What is Design for Manufacturability (DFM), and why is it important in SMT ordering?

Design for Manufacturability (DFM) refers to the practice of designing PCBs in a way that considers the limitations and requirements of the manufacturing process. DFM issues can lead to manufacturing delays, reduced yields, and increased costs. By involving the manufacturer early in the design process and adhering to industry-standard DFM guidelines, you can minimize these issues and ensure a smoother manufacturing process. -

How can I streamline my SMT ordering process?

To streamline your SMT ordering process, develop and maintain a comprehensive component library, establish standardized file formats and naming conventions, implement automated file generation tools, foster a collaborative relationship with your PCB assembly manufacturer, and continuously monitor and analyze SMT ordering metrics to identify areas for improvement.

No responses yet