1. Missing or Incorrect Layers

One of the most common mistakes in Gerber files is missing or incorrect layers. This can happen when the designer forgets to include a necessary layer or accidentally includes an unnecessary one.

To avoid this mistake:

– Double-check that all required layers are included (e.g., top copper, bottom copper, soldermask, silkscreen)

– Verify that the correct file extension is used for each layer (e.g., .GTL for top copper, .GBL for bottom copper)

– Review the layer order to ensure it matches your manufacturer’s specifications

2. Incorrect Aperture Definitions

Aperture definitions specify the shapes and sizes of pads, traces, and other features in your PCB design. Incorrect aperture definitions can lead to manufacturing issues and a non-functional board.

To avoid this mistake:

– Use a standard aperture list or provide a custom aperture list with your Gerber files

– Verify that the aperture sizes match your design intent

– Ensure that the aperture file is included with your Gerber files

3. Overlapping or Conflicting Features

Overlapping or conflicting features can cause short circuits, open circuits, or other manufacturing defects. This often occurs when traces or pads are too close together or when copper pours overlap with other features.

To avoid this mistake:

– Follow your manufacturer’s design rules for minimum clearances and trace widths

– Use a design rule check (DRC) tool to identify and resolve overlapping or conflicting features

– Visually inspect your design for any apparent conflicts or overlaps

4. Incorrect Units or Scale

Gerber files can be generated in either metric (mm) or imperial (inch) units. Using the wrong units or scale can result in a PCB that is either too small or too large, making it unusable.

To avoid this mistake:

– Specify the correct units when generating your Gerber files

– Verify that the scale is set to 1:1 (actual size)

– Communicate the units and scale to your manufacturer to avoid confusion

5. Insufficient or Excessive Copper Clearance

Copper clearance refers to the space between copper features, such as traces and pads. Insufficient clearance can lead to short circuits, while excessive clearance can make routing more difficult and reduce the available board space.

To avoid this mistake:

– Follow your manufacturer’s recommendations for minimum copper clearance

– Use a DRC tool to ensure that your design meets the specified clearance requirements

– Consider the voltage and current requirements of your design when determining appropriate clearances

6. Incorrect Drill File Format or Alignment

Drill files specify the location and size of holes in your PCB, including vias and component mounting holes. Incorrect drill file format or alignment can cause misaligned or missing holes.

To avoid this mistake:

– Use the correct file format for your drill files (e.g., Excellon)

– Ensure that the drill file units match the Gerber file units

– Verify that the drill file origin aligns with the Gerber file origin

– Include a drill map or drawing to help your manufacturer understand the hole locations and sizes

7. Incomplete or Inaccurate Documentation

Providing complete and accurate documentation is essential for ensuring a smooth manufacturing process. Missing or inaccurate information can lead to delays, misunderstandings, and potentially costly mistakes.

To avoid this mistake:

– Include a README file with your Gerber files that provides essential information, such as:

– PCB dimensions

– Layer stack-up

– Surface finish

– Special requirements or instructions

– Provide a bill of materials (BOM) that lists all components used in your design

– Include assembly drawings or screenshots to help your manufacturer understand the component placement and orientation

FAQ

1. What are Gerber files?

Gerber files are a standard file format used in the PCB industry to describe the layout of a printed circuit board. They contain information about the copper layers, soldermask, silkscreen, and drill holes required to manufacture a PCB.

2. Why is it important to avoid Gerber File Mistakes?

Avoiding Gerber file mistakes is crucial because errors can lead to manufacturing delays, additional costs, or even a non-functional PCB. By ensuring the accuracy and completeness of your Gerber files, you can streamline the manufacturing process and receive a high-quality PCB that meets your design intent.

3. What tools can I use to check my Gerber files for mistakes?

There are several tools available to check your Gerber files for mistakes, including:

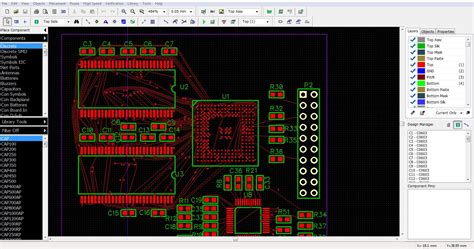

– Gerber viewers: These tools allow you to visually inspect your Gerber files and check for errors or inconsistencies.

– Design rule check (DRC) tools: DRC tools can help identify design issues, such as overlapping features or insufficient clearances, before generating Gerber files.

– Manufacturer-provided tools: Some PCB manufacturers offer online tools or services to help you verify your Gerber files before submitting them for production.

4. How can I ensure that my Gerber files are compatible with my manufacturer’s requirements?

To ensure compatibility with your manufacturer’s requirements, follow these steps:

1. Consult your manufacturer’s design guidelines and specifications.

2. Use a standard aperture list or provide a custom aperture list that meets your manufacturer’s requirements.

3. Specify the correct units and scale when generating your Gerber files.

4. Provide complete and accurate documentation, including a README file, BOM, and assembly drawings.

5. Communicate with your manufacturer to clarify any questions or concerns.

5. What should I do if I discover a mistake in my Gerber files after submitting them for manufacturing?

If you discover a mistake in your Gerber files after submitting them for manufacturing, contact your manufacturer immediately. Depending on the nature and severity of the mistake, they may be able to correct the issue before proceeding with production. In some cases, you may need to generate new Gerber files and resubmit them, which could result in delays or additional costs.

Conclusion

Avoiding common Gerber file mistakes is essential for ensuring a smooth and successful PCB manufacturing process. By following the tips and best practices outlined in this article, you can minimize the risk of errors and delays, ultimately saving time and money. Remember to double-check your files, use appropriate tools for verification, and provide clear and complete documentation to your manufacturer. With attention to detail and effective communication, you can create high-quality Gerber files that result in a functional and reliable PCB.

No responses yet