Introduction to SMT and THT Mounting Techniques

In the world of electronics manufacturing, there are two primary methods for mounting components onto printed circuit boards (PCBs): Surface Mount Technology (SMT) and Through-Hole Technology (THT). Both techniques have their advantages and disadvantages, and the choice between them depends on various factors such as the type of components, the desired reliability, and the production volume.

What is Surface Mount Technology (SMT)?

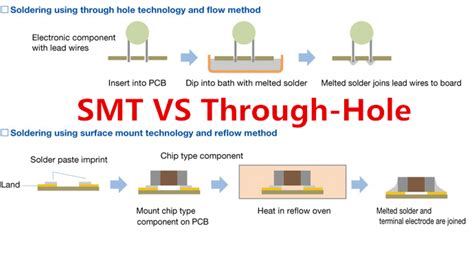

Surface Mount Technology (SMT) is a method of mounting electronic components directly onto the surface of a PCB. In this technique, the components are placed on top of the board and soldered to pads or lands on the surface. SMT components are typically smaller than their THT counterparts and have either small leads or no leads at all.

What is Through-Hole Technology (THT)?

Through-Hole Technology (THT) is a method of mounting electronic components by inserting their leads through holes drilled in the PCB. The leads are then soldered to pads on the opposite side of the board. THT components are generally larger than SMT components and have long leads that are inserted into the holes.

Advantages and Disadvantages of SMT vs THT

Advantages of SMT

-

Smaller component size: SMT components are typically smaller than THT components, allowing for higher component density on the PCB.

-

Reduced PCB size: With smaller components and higher density, SMT allows for smaller PCB sizes, which can lead to more compact devices.

-

Faster assembly: SMT components can be placed and soldered onto the PCB using automated equipment, which enables faster assembly times compared to THT.

-

Lower production costs: The faster assembly times and the ability to use automated equipment can result in lower production costs for high-volume manufacturing.

-

Improved high-frequency performance: SMT components have shorter leads, which can reduce parasitic inductance and capacitance, resulting in better high-frequency performance.

Disadvantages of SMT

-

Difficulty in manual assembly: Due to the small size of SMT components, manual assembly can be challenging and requires specialized tools and skills.

-

Higher initial setup costs: Setting up an SMT Assembly line requires significant investment in equipment and training, which can be more expensive than THT assembly.

-

Limited heat dissipation: SMT components have less surface area in contact with the PCB, which can limit their ability to dissipate heat.

Advantages of THT

-

Stronger mechanical bonds: THT components have leads that extend through the PCB, creating stronger mechanical bonds that can withstand higher levels of stress and vibration.

-

Easier manual assembly: THT components are larger and have longer leads, making them easier to handle and solder manually.

-

Better heat dissipation: THT components have more surface area in contact with the PCB, allowing for better heat dissipation.

-

Lower initial setup costs: Setting up a THT assembly line is generally less expensive than an SMT assembly line, as it requires less specialized equipment.

Disadvantages of THT

-

Larger component size: THT components are typically larger than SMT components, which can limit the component density on the PCB.

-

Larger PCB size: With larger components and lower density, THT generally requires larger PCB sizes compared to SMT.

-

Slower assembly: THT components must be inserted into holes and soldered manually or with less advanced automation, resulting in slower assembly times compared to SMT.

-

Higher production costs for high-volume: The slower assembly times and the need for more manual labor can result in higher production costs for high-volume manufacturing.

Comparison Table: SMT vs THT

| Factor | Surface Mount Technology (SMT) | Through-Hole Technology (THT) |

|---|---|---|

| Component size | Smaller | Larger |

| PCB size | Smaller | Larger |

| Assembly speed | Faster | Slower |

| Production costs | Lower for high-volume | Higher for high-volume |

| High-frequency performance | Better | Worse |

| Manual assembly | More difficult | Easier |

| Initial setup costs | Higher | Lower |

| Heat dissipation | Limited | Better |

| Mechanical strength | Weaker | Stronger |

Applications of SMT and THT

When to use SMT

-

High-volume production: SMT is the preferred choice for high-volume production due to its faster assembly times and lower production costs.

-

Compact devices: SMT allows for smaller components and higher density, making it ideal for compact devices such as smartphones, smartwatches, and portable electronics.

-

High-frequency applications: SMT components have better high-frequency performance, making them suitable for applications such as wireless communication devices and high-speed digital circuits.

When to use THT

-

Low-volume production: THT can be more cost-effective for low-volume production due to its lower initial setup costs and the ability to use manual assembly.

-

High-power applications: THT components can dissipate heat better, making them suitable for high-power applications such as power supplies and motor controllers.

-

Mechanical stress: THT components have stronger mechanical bonds, making them suitable for applications that are subject to high levels of stress and vibration, such as automotive electronics and industrial controls.

Mixed Assembly: Combining SMT and THT

In some cases, it may be beneficial to use a combination of SMT and THT components on the same PCB. This approach, known as mixed assembly, allows designers to take advantage of the strengths of both technologies.

Mixed assembly can be used when a design requires components that are not available in SMT packages, or when certain components need to withstand higher levels of stress or heat dissipation. In such cases, the SMT components can be used for the majority of the board, while THT components are used for specific parts that require their unique properties.

Future Trends in SMT and THT

As electronic devices continue to become smaller, more powerful, and more complex, the demand for advanced assembly technologies will continue to grow. Some of the future trends in SMT and THT include:

-

Miniaturization: The development of smaller SMT components and finer pitch sizes will enable even higher component density and smaller PCB sizes.

-

Advanced materials: The use of advanced materials, such as high-temperature solders and low-loss dielectrics, will improve the performance and reliability of both SMT and THT assemblies.

-

3D printing: The integration of 3D printing technology with electronics manufacturing may enable the creation of complex, three-dimensional PCB structures that combine SMT and THT components in novel ways.

-

Automation and AI: The increasing use of automation and artificial intelligence in electronics manufacturing will further optimize the assembly process, improve quality control, and reduce production costs.

Frequently Asked Questions (FAQ)

-

Q: Can SMT and THT components be used on the same PCB?

A: Yes, it is possible to use a combination of SMT and THT components on the same PCB. This approach is known as mixed assembly and can be used when specific components are not available in SMT packages or require the unique properties of THT mounting. -

Q: Which technology is better for prototyping, SMT or THT?

A: THT is often preferred for prototyping due to its easier manual assembly and lower initial setup costs. However, as prototypes become more complex and require smaller components, SMT may be necessary. -

Q: Can SMT components be soldered manually?

A: While it is possible to solder SMT components manually, it can be challenging due to their small size. Manual SMT assembly requires specialized tools, such as tweezers and a fine-tipped soldering iron, as well as a steady hand and good eyesight. -

Q: Are THT components becoming obsolete?

A: While SMT has become the dominant technology in electronics manufacturing, THT components are still widely used in certain applications that require their unique properties, such as high-power handling or mechanical strength. As such, THT is not likely to become obsolete in the near future. -

Q: Which technology is more environmentally friendly, SMT or THT?

A: SMT is generally considered more environmentally friendly than THT, as it uses less material (due to smaller component sizes) and produces less waste during the assembly process. Additionally, the ability to use automated assembly equipment reduces the energy consumption and emissions associated with manual labor.

Conclusion

In summary, Surface Mount Technology (SMT) and Through-Hole Technology (THT) are two distinct methods for mounting electronic components onto printed circuit boards. Each technology has its own advantages and disadvantages, and the choice between them depends on factors such as the type of components, desired reliability, production volume, and cost.

SMT is characterized by smaller component sizes, higher component density, faster assembly times, and lower production costs for high-volume manufacturing. On the other hand, THT offers stronger mechanical bonds, easier manual assembly, better heat dissipation, and lower initial setup costs.

In some cases, a combination of SMT and THT components can be used on the same PCB to take advantage of the strengths of both technologies. As electronic devices continue to evolve, future trends in SMT and THT will likely focus on miniaturization, advanced materials, 3D printing, and increased automation and AI integration.

Ultimately, understanding the differences between SMT and THT, as well as their respective applications, is crucial for designers, engineers, and manufacturers in the electronics industry to make informed decisions and create products that meet the ever-changing demands of the market.

No responses yet